A method for producing ethanol by fermenting raw materials of tobacco stalks

A tobacco stalk and raw material technology, applied in the field of ethanol production by fermenting tobacco stalk raw materials, can solve the problems of waste of agricultural surplus resources and environmental pollution, and achieve the effects of rational development and utilization, reduction of environmental pollution, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

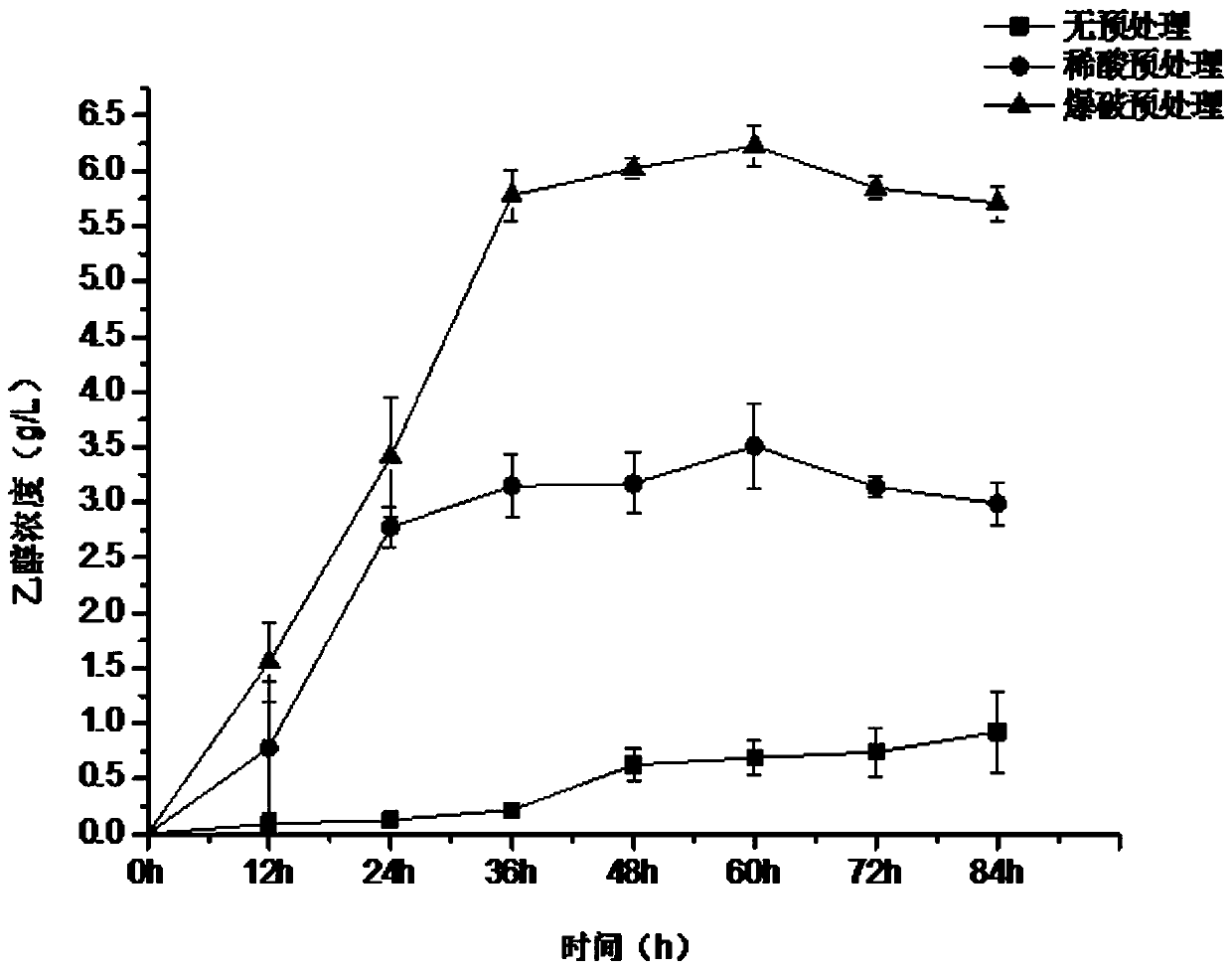

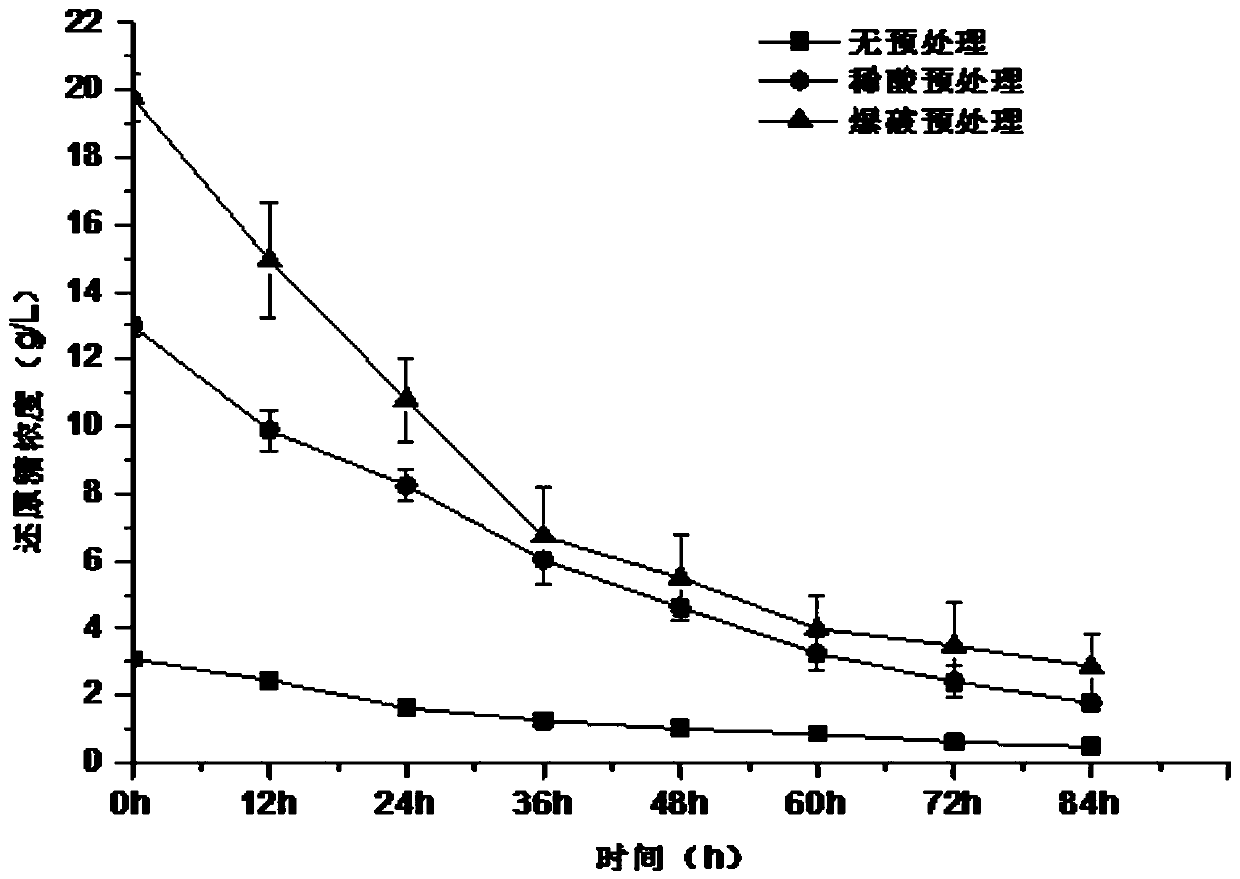

Embodiment 1

[0021] A method for producing ethanol by fermenting raw materials of tobacco stalks, comprising the following steps:

[0022] ① Pretreatment of raw materials: crush the tobacco stalks to 10 meshes, and then perform steam explosion pretreatment on the crushed tobacco stalks. The explosion pressure is 2.0 MP, the pressure holding time is 2.5 minutes, and then the pressure is released to normal pressure instantly;

[0023] ② Enzymatic hydrolysis and saccharification of materials: add water to the tobacco stalks pretreated by steam explosion, mix, and stir to form a uniform solid-liquid mixture. The solid-liquid ratio of tobacco stalks and added water is 1:8 (kg / L); 10 mol / L sodium hydroxide was used to adjust the pH value of the solid-liquid mixture to 4.8, then cellulase and xylanase were added, and at 48°C, 120 r / min shaker was used for enzymolysis for 48 hours, and then filtered to obtain the enzymolysis solution ; Wherein the addition amount of cellulase is 15 FPU / g tobacco s...

Embodiment 2

[0036] A method for producing ethanol by fermenting raw materials of tobacco stalks, comprising the following steps:

[0037] ①Pretreatment of raw materials: crush the tobacco stalks to 50 meshes, and then perform steam explosion pretreatment on the crushed tobacco stalks. The blasting pressure is 2.5MP, the pressure holding time is 1min, and then the pressure is released to normal pressure instantly;

[0038] ② Enzymatic hydrolysis and saccharification of materials: add water to the tobacco stalks pretreated by steam explosion, mix, and stir to form a uniform solid-liquid mixture. The solid-liquid ratio of tobacco stalks and added water is 1:5 (kg / L); 10 mol / L sodium hydroxide was used to adjust the pH value of the solid-liquid mixture to 4.5, then cellulase and xylanase were added, and at 45°C, 120 r / min shaker was shaken for 36 hours, and filtered to obtain the enzymolysis solution , wherein, the addition amount of cellulase is 50 FPU / g tobacco stalk, and the addition amoun...

Embodiment 3

[0045] A method for producing ethanol by fermenting raw materials of tobacco stalks, comprising the following steps:

[0046] ①Pretreatment of raw materials: crush the tobacco stalks to 100 mesh, and then perform steam explosion pretreatment on the crushed tobacco stalks, the blasting pressure is 1.5 MP, the pressure holding time is 5 minutes, and then the pressure is released to normal pressure instantly;

[0047] ② Enzymatic hydrolysis and saccharification of materials: add water to the tobacco stalks pretreated by steam explosion, mix, and stir to form a uniform solid-liquid mixture. The solid-liquid ratio of tobacco stalks and added water is 1:10 (kg / L); 10 mol / L sodium hydroxide was used to adjust the pH value of the solid-liquid mixture to 4.5, then cellulase and xylanase were added, and at 45°C, 120 r / min shaker was used for enzymolysis for 48 hours, and then filtered to obtain the enzymolysis solution ; Wherein, the addition amount of cellulase is 30 FPU / g tobacco stal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com