Silicon-containing tung oil-based alkyd resin as well as preparation method and application of alkyd resin

A technology of alkyd resin and tung oil, applied in the direction of coating, can solve the problems of water resistance and poor heat resistance of alkyd resin, and achieve the effects of stable product quality, easy industrial expansion of production, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0027] Add 5g of tung oil and the calculated amount of maleic anhydride to a 25mL disposable light-transmitting vial, put it into a polytetrafluoroethylene reactor and seal it with a cap. The reactor is placed on a polypropylene rotatable chassis and secured with bolts. Then put the whole device into Ethos MicroSYNTH 1600 microwave synthesizer (Milestone Company, USA), and carry out microwave heating reaction while rotating. , the reaction pressure is controlled by the temperature of the closed system. Its product is light yellow thin transparent liquid to dark brown opaque liquid. The reaction conditions such as the proportion of reaction raw materials, reaction power, reaction time, amount of catalyst added, and whether to pressurize are shown in the table below. After the reaction was complete, vacuum was used to remove unreacted maleic anhydride. Under optimal conditions, the acid value of the maleinized oil is 44.9-187.9 mgKOH / g, that is, the number of maleic anhydride...

Embodiment 13

[0032] Add 10g of tung oil and 0.9g of maleic anhydride to a 50mL three-neck round bottom flask, heat and stir in an oil bath and pass nitrogen gas. When the temperature rises to 80°C, react for 1h. Continue to add 0.9g of maleic anhydride, raise the temperature to 100°C, and react for 1h. Finally, 0.9 g of maleic anhydride was added, the temperature was raised to 120° C., and the reaction was carried out for 1 h. Finally, a light brown transparent liquid was obtained. After vacuum purification of the obtained maleic anhydride soybean oil, the acid value is about 203.1 mgKOH / g, that is, the number of maleic anhydride attached to each fatty acid chain is 0.60.

Embodiment 14

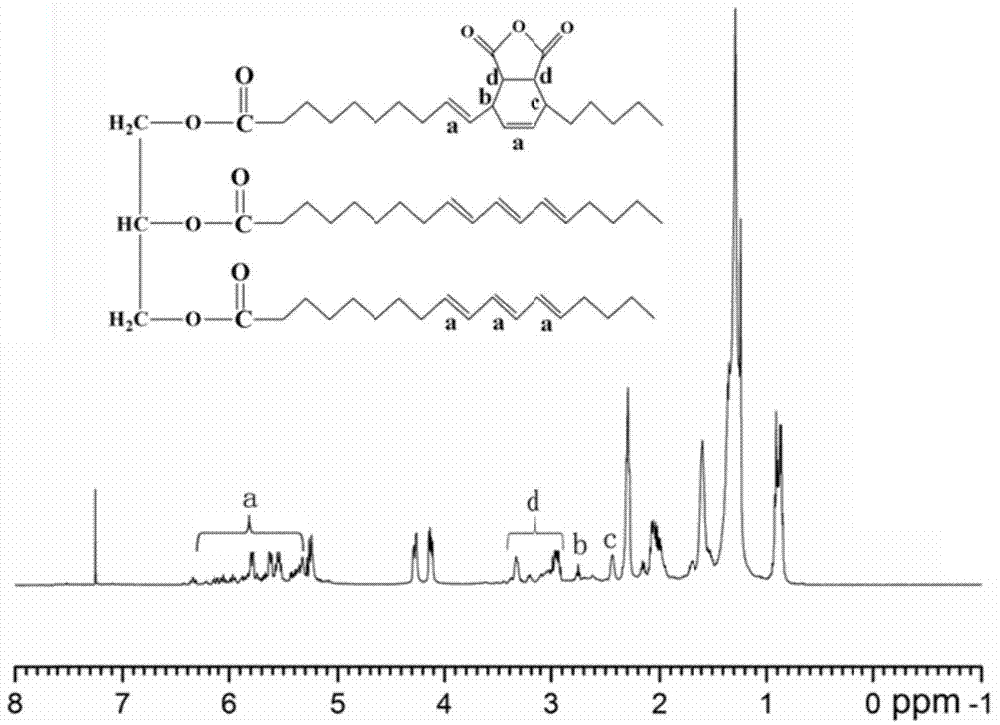

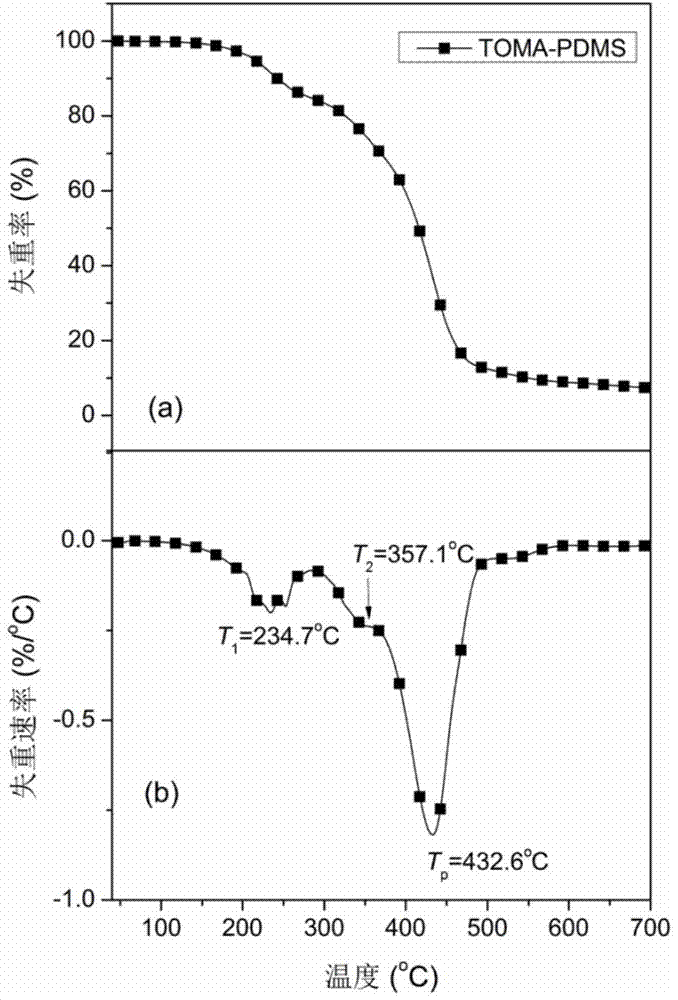

[0034] Add maleic anhydrided tung oil (Example 3) and hydroxyl-terminated polydimethylsiloxane with a molecular weight of 550 into a 40mL light-transmitting vial, wherein the ratio of anhydride to hydroxyl is 1:2, and add 1% of the total weight of the reaction system 2-methylimidazole was stirred at 110°C for 3h, then the mixture was poured into a preheated silica gel mold and degassed for 15min at a temperature of 110°C. It was placed in an oven, cured at 120°C for 24h and post-treated at 160°C for 2h. Finally, a light brown opaque silicon-containing tung oil alkyd resin was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com