Polyurethane water blocking agent and its preparation method and use method

A polyurethane and water blocking agent technology, applied in the field of polyurethane, can solve the problems of long curing time, unadjustable speed, poor waterproof performance, etc., and achieve the effects of fast reaction speed, long storage period, excellent fluidity and cohesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw materials of component A are:

[0040]

[0041] The raw materials of component B are:

[0042] Polyoxypropylene Triol 330N: 20

[0043] Diethylene glycol diethyl ether: 10

[0044] Triethylenediamine: 20

[0045] Component A is prepared by the following steps: Put the polyoxypropylene triol MN-1000 based on the formula into the reactor at room temperature, raise it to 100 to 120°C, stir, vacuumize and dehydrate for 2-3 hours, and cool down Add isocyanate PM-200 to 10-40°C, react at 80-85°C for 2-3 hours, cool down to 30-40°C, add dibutyl phthalate, acetone, water-soluble silicone oil and phosphoric acid, mix well, and pack into barrels .

[0046] Component B is prepared through the following steps: Put the measured 330N, diethylene glycol diethyl ether, and triethylenediamine into the reaction kettle, stir at room temperature for 2-3 hours, and then fill the barrel.

[0047] The properties of the polyurethane water blocking agent product in this example ...

Embodiment 2

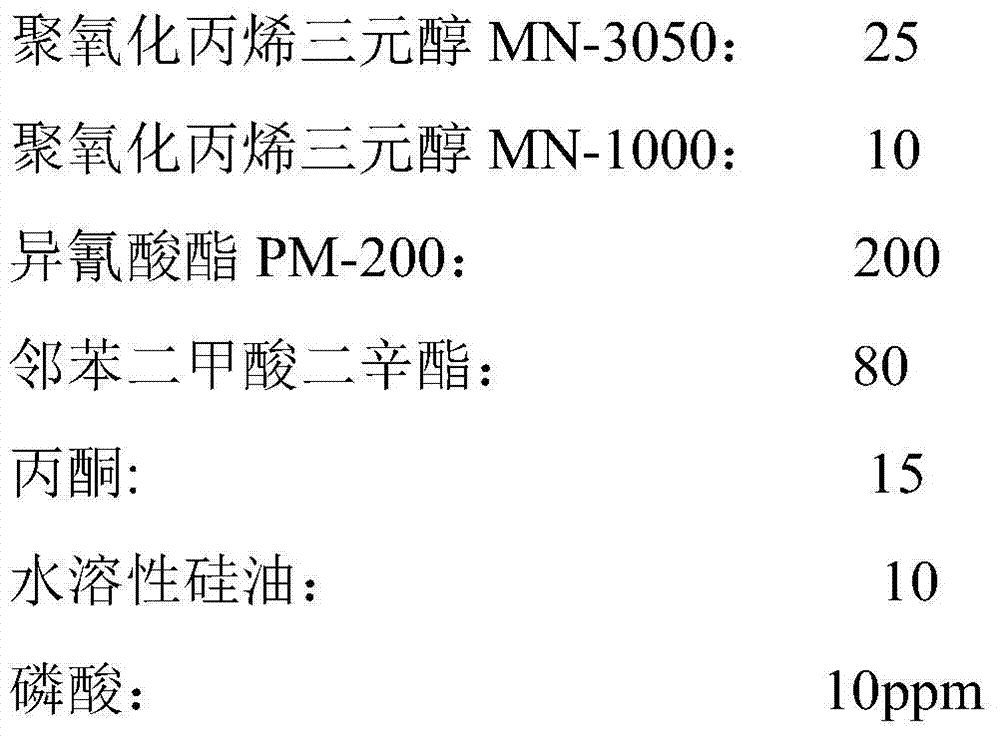

[0051] The raw materials of component A are:

[0052]

[0053] The raw materials of component B are:

[0054] Polyoxypropylene Triol 330N: 30

[0055] Ethylene glycol diethyl ether: 20

[0056] Triethylenediamine: 25

[0057] Component A is prepared by the following steps: Put the polyoxypropylene triol MN-3050 and polyoxypropylene triol MN-1000 based on the formula into the reactor at room temperature, raise the temperature to 100 to 120 °C, stir, pump Vacuum dehydration and degassing for 2-3 hours, cool down to 10-40°C, add isocyanate PM-200, react at 80-85°C for 2-3 hours, cool down to 30-40°C, add dioctyl phthalate, acetone, Stir the water-soluble silicone oil and phosphoric acid evenly, and pack into barrels.

[0058] Component B is prepared by the following steps: Put the measured polyoxypropylene triol 330N, ethylene glycol diethyl ether, and triethylenediamine into the reaction kettle, stir at room temperature for 2-3 hours, and then fill the barrel .

[0059] T...

Embodiment 3

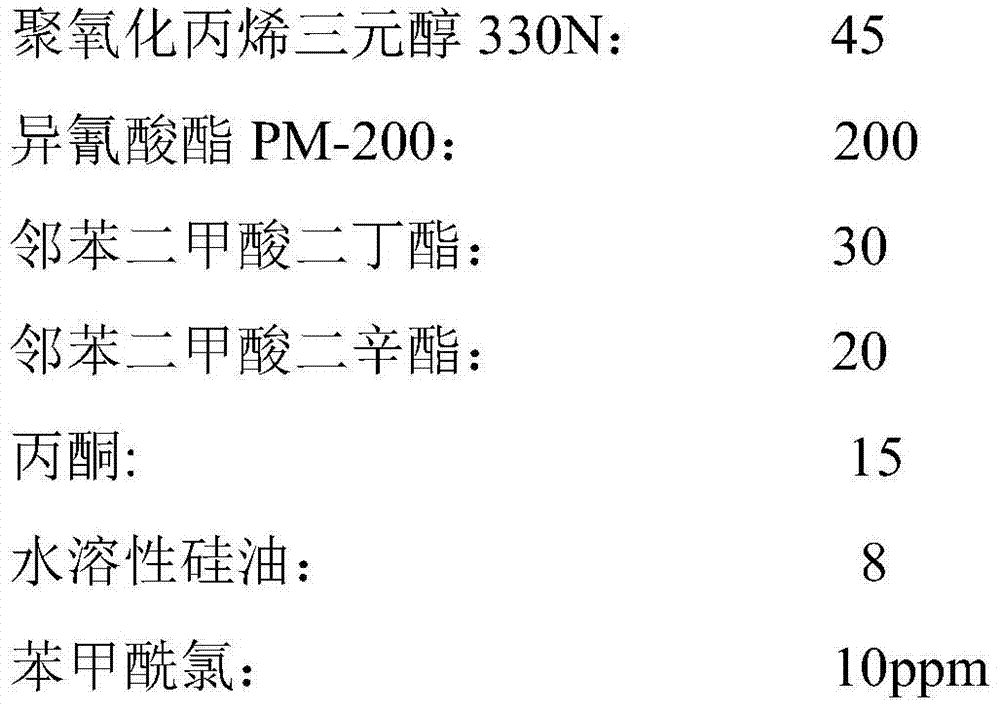

[0063] The raw materials of component A are:

[0064]

[0065] The raw materials of component B are:

[0066]

[0067] Preparation of component A: Put the 330N based on the formula into the reaction kettle at room temperature, raise it to 100 to 120°C, stir, vacuumize and dehydrate and degas for 2-3 hours, cool down to 10-40°C, add isocyanate PM-200, at 80 React at -85°C for 2-3 hours, cool down to 30-40°C, add dioctyl phthalate, dibutyl phthalate, acetone, water-soluble silicone oil and phosphoric acid, stir evenly, and pack into barrels.

[0068] Preparation of component B: Put the measured polyoxypropylene triol MN-3050, diethylene glycol diethyl ether, ethylene glycol diethyl ether, and triethylenediamine into the reaction kettle, and stir at room temperature for 2-3 hours, that is Can be barreled.

[0069] The properties of the polyurethane water blocking agent product in this example are as follows: the viscosity (25° C.) is: 230 mPa·s for component A, and 72 mPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com