Extraction method of Homoharringtonine through microbial fermentation and application of Homoharringtonine

A technology for homoharringtonine and microbial fermentation, which is applied in the field of bioengineering to achieve the effect of facilitating purification and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1 microbial fermentation

[0083] Taking Alternaria tentoides CH1307 (preservation number CGMCC No.4443) as an example, Example 1 of the present invention provides a method for producing homoharringtonine by microbial fermentation, specifically referring to the inventor's authorized patent (Application No. : 201110028195.7) "A method for preparing homoharringtonine and a special strain" on page 8 of Example 2 (method for preparing homoharringtonine) 1-3 steps; obtain Alternaria tenopolaris CH1307 fermentation product.

Embodiment 2

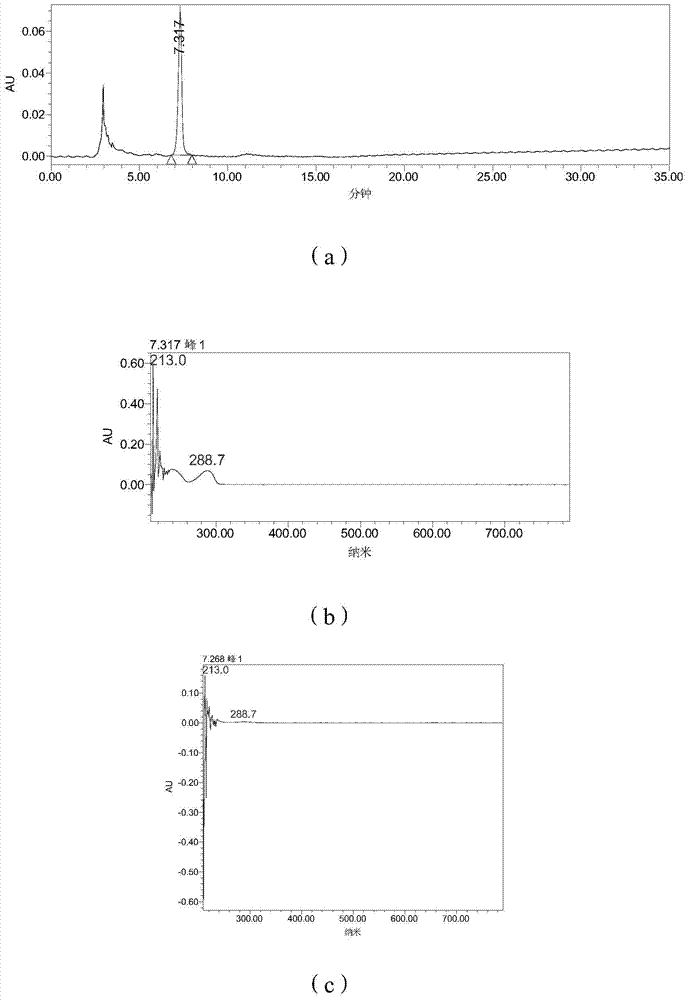

[0084] Example 2 Purification of Homoharringtonine from the Fermentation Broth Removed from Bacteria

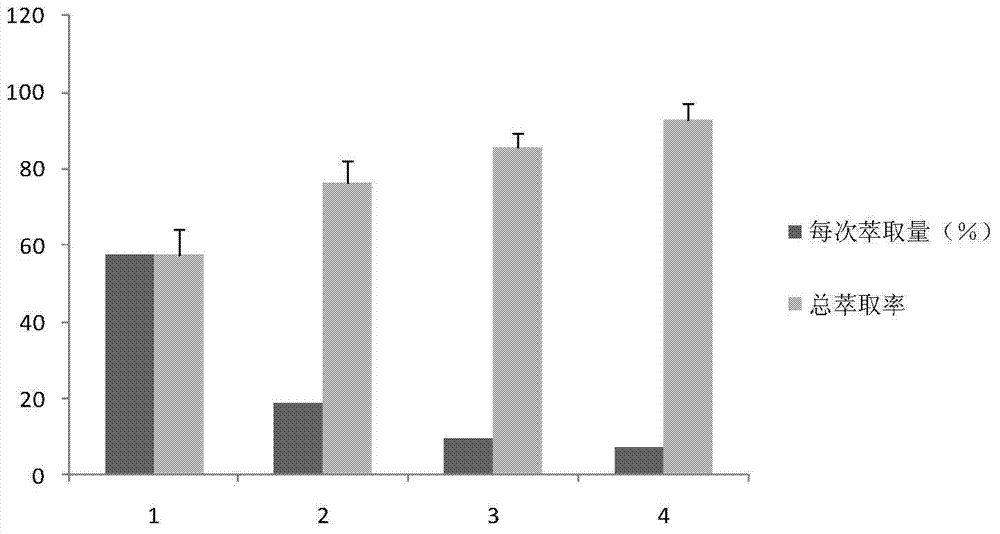

[0085] (1) Centrifuge and suction-filter the fermented material of Alternaria tenopolaris CH1307 in Example 1 to obtain 10 L of fermented liquid from which mycelium has been removed, concentrate it to 400 mL by rotary evaporation at 45° C., and adjust the pH to 8.0. Extract with chloroform four times, 100 mL each time, combine the organic phases and spin dry, redissolve in 0.05 mol / L, pH 9.0 ammonia-ammonium chloride buffer solution 100 mL.

[0086](2) The reconstituted extract was stirred and adsorbed with 10 g of NKA-9 macroporous resin for 1 h, filtered and washed twice with a small amount of the above-mentioned ammonia-ammonium chloride buffer solution. The resin was placed in 0.1mol / L pH 5.0 citric acid buffer solution:methanol (3:7) for desorption for 2h, filtered and rinsed twice with a small amount of the above desorption solution, the combined filtrate was concentrat...

Embodiment 3

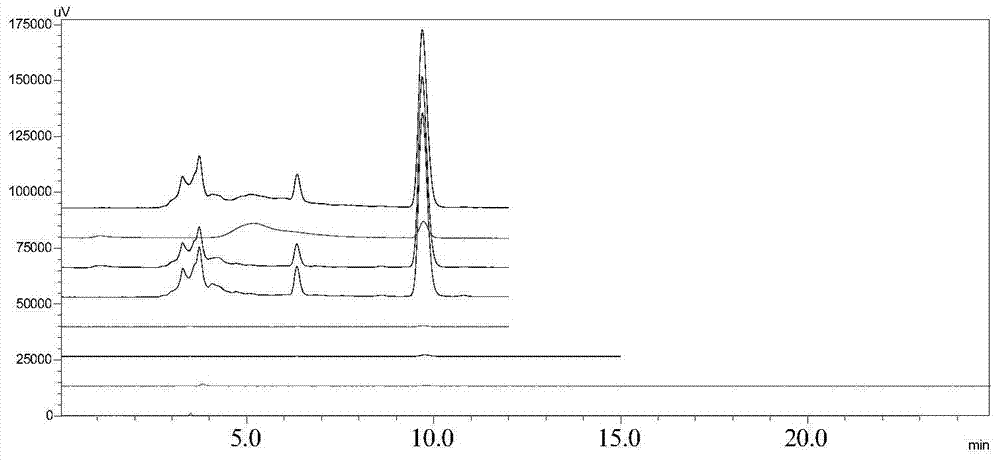

[0089] Example 3 Purification of Homoharringtonine from Fermentation Broth Removed from Bacteria

[0090] (1) Centrifuge and suction-filter the fermented product of Alternaria tenopolaris CH1307 in Example 1 to obtain 20 L of fermentation broth from which mycelium has been removed, concentrate it to 500 mL by rotary evaporation at 45° C., and adjust the pH to 8.0. Extract 4 times with chloroform, 125 mL each time, combine the organic phases and spin dry, and redissolve in 200 mL of 0.05 mol / L, pH 9.0 ammonia-ammonium chloride buffer solution.

[0091] (2) The reconstituted extract was statically adsorbed with 20 g of NKA-9 macroporous resin for 1 hour, filtered and washed twice with a small amount of the above-mentioned ammonia-ammonium chloride buffer solution. The resin was placed in 0.1mol / L pH 5.0 citric acid buffer solution:methanol (3:7) for desorption for 2h, filtered and washed twice with a small amount of the above desorption solution, the combined filtrate was concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com