Method and device for preparing high-purity boric acid

A technology of high-purity boric acid and boric acid, which is applied in the direction of boron oxide compounds, etc., can solve the problems of complex preparation process and low purity of high-purity boric acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares the device of high-purity boric acid

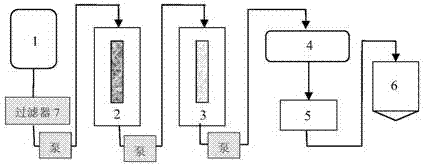

[0027] Such as figure 1 As shown, the device for preparing high-purity boric acid includes a saturated solution premixer 1, a filter 7, a cation exchange column 2, an anion exchange column 3, an evaporation device 4, a cooling crystallization container 5 and a suction filtration drying device 6 connected in sequence. Water pumps are installed between the filter 7 and the cation exchange column 2 , between the cation exchange column 2 and the anion exchange column 3 , and between the anion exchange column 3 and the evaporator 4 .

Embodiment 2

[0028] Embodiment 2 prepares high-purity boric acid

[0029] The raw material is industrial-grade boric acid. Prepare 10L of saturated boric acid solution at 30°C. If there is obvious precipitation after dissolution, it needs to be filtered. First pass the prepared saturated boric acid solution through a cation exchange column, the inner diameter of the column is 30 mm, the height of the cation exchange resin in the column is 400 mm, and the filling material is the cation exchange resin produced by Zhejiang Zhengguang Industrial Co., Ltd. ℃. Pump the boric acid solution that has passed through the cation exchange column into the anion exchange column. The inner diameter of the column is 30mm, and the height of the anion exchange resin in the column is 400mm. The filling material is anion exchange resin produced by Zhejiang Zhengguang Industrial Co., Ltd. min, keep at 30°C. Then pump the boric acid solution that has passed through the anion exchange column into the evaporatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com