Method and device for conveying bottles arrayed in double rows

A technology for arranging conveying devices and bottles, which is applied in the directions of conveyor control devices, conveyor objects, transportation and packaging, etc. Bacteria and other problems to achieve the effect of ensuring a clean environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

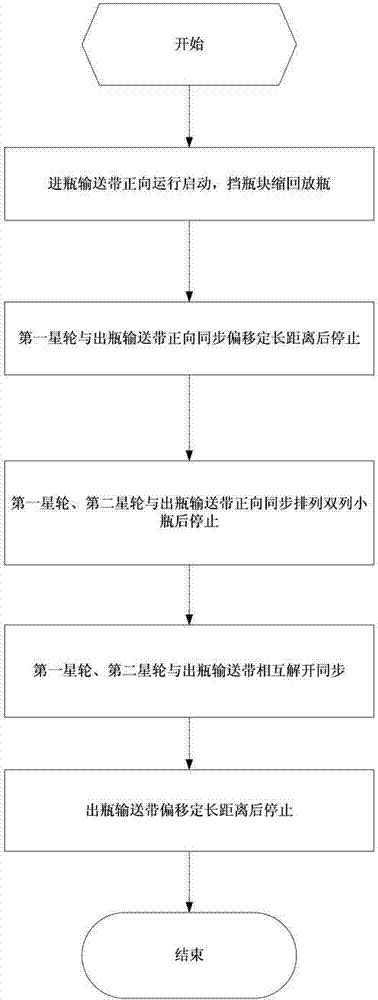

[0059] like Figure 1 to Figure 15 As shown, the double-row bottle arrangement conveying method of the present embodiment comprises the following steps:

[0060] 1) The bottle infeed conveyor belt 8 runs in the forward direction and starts to convey the double-row small bottles 9, the first bottle stopper 19 and the second bottle stopper 21 are retracted to release the bottles, when the first small bottle row length detection part 1 and the second round of front bottle inspection Component 22, the first small bottle column length detection component 1, and the second round of front bottle inspection component 22 detect that there is a bottle, and the outlet bottle positions of the first star wheel 4 and the second star wheel 23 are at the same initial position, that is, the outlet bottle position The angle between the tangent of the notch and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com