A three-dimensional braided composite material propeller blade for ships and its preparation method

A three-dimensional weaving, composite material technology, applied in the direction of rotating propellers, rotary propellers, etc., can solve problems such as poor bonding strength, and achieve the effect of improving strength and stiffness, high material uniformity and dimensional precision, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

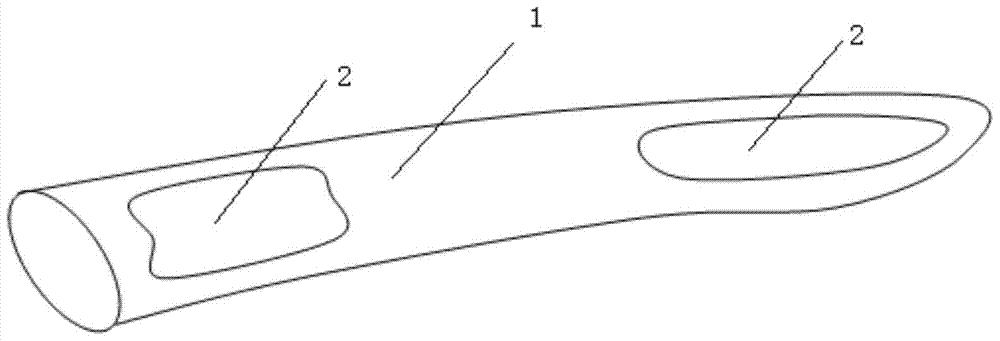

[0032] figure 1 It is a structural schematic diagram of the core mold of the propeller blade of the present invention, and the core mold includes a core mold main body 1 and a structural reinforcement part 2 arranged on the core mold main body. The three-dimensional braided structure of the propeller blade of the present invention is based on figure 1 The mold structure in the weaving molding.

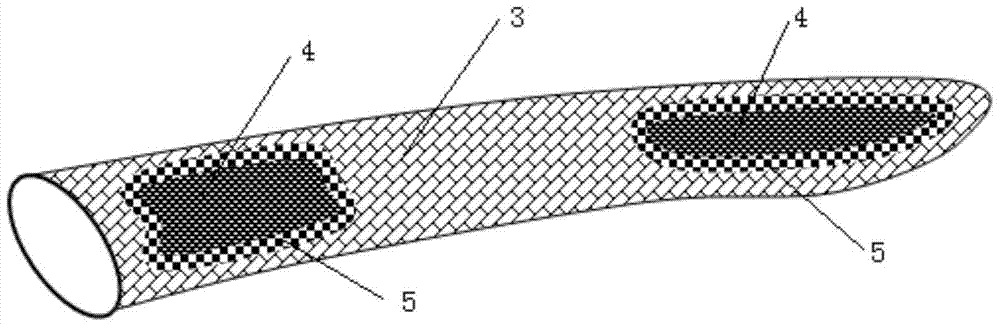

[0033] Such as figure 2 As shown, a propeller blade of a three-dimensional braided composite material for a ship includes an internal three-dimensional braided structure and a resin layer impregnated and cured on the three-dimensional braided structure, and the three-dimensional braided structure includes a main body of the three-dimensional braided structure Part 3, the reinforced structure part 4 of the three-dimensional braided structure, and the high-density yarn stitching structure between the main body part 3 of the three-dimensional braided structure and the reinforced struct...

Embodiment 2

[0037] based on figure 1 The core mold in the hybrid fiber three-dimensional braided preform is prepared, such as figure 2 As shown, the main part 3 of the three-dimensional braided structure uses T300 carbon fiber and Kevlar29 aramid fiber hybrid yarn for mixed weaving, and the reinforcing structure part 4 of the three-dimensional braided structure uses two hybrid combinations of Kevlar49 aramid fiber and T700 carbon fiber. . The overall three-dimensional braided propeller blade has a length of 5m and a width of 1.2m.

[0038] The hybrid fiber blade preform after three-dimensional weaving uses phenolic resin glue as the base material, and the VARI vacuum introduction process is used to fully impregnate the above blade preform with the glue, and the vacuum degree of the entire impregnation and compounding process is kept at 0.1MPa. The resin-impregnated blades were cured at 120°C for 4 hours and then molded, with the glue content kept at 40%.

Embodiment 3

[0040] based on figure 1 The core mold in the hybrid fiber three-dimensional braided preform is prepared, such as figure 2 As shown, the main part 3 of the three-dimensional braided structure uses T700 carbon fiber and Kevlar49 aramid fiber hybrid yarn for mixed weaving, and the reinforcing structure part 4 of the three-dimensional braided structure can choose Kevlar29 aramid fiber and T800 carbon fiber. combination. The length of the propeller blade after overall three-dimensional weaving is 4m and the width is 0.8m.

[0041]The hybrid fiber blade prefabricated body after three-dimensional weaving uses epoxy resin glue as the matrix raw material, and uses the VARI vacuum introduction process to fully impregnate the above blade prefabricated body with the glue, and the vacuum degree of the entire impregnation composite process is kept at 0.06MPa. The resin-impregnated blades were cured at 90°C for 2.5 hours and then molded, with the glue content kept at 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com