Rubber plasticator

A plasticizer and rubber technology is applied in the field of rubber plasticizers to avoid waste of raw materials, speed up plasticization and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

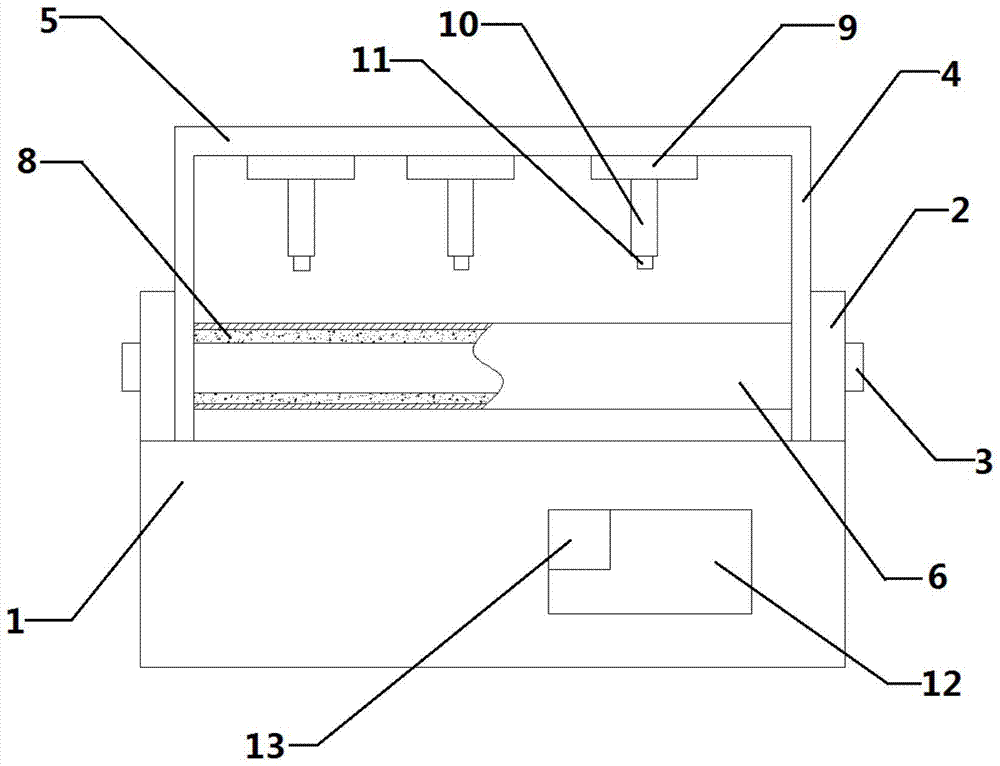

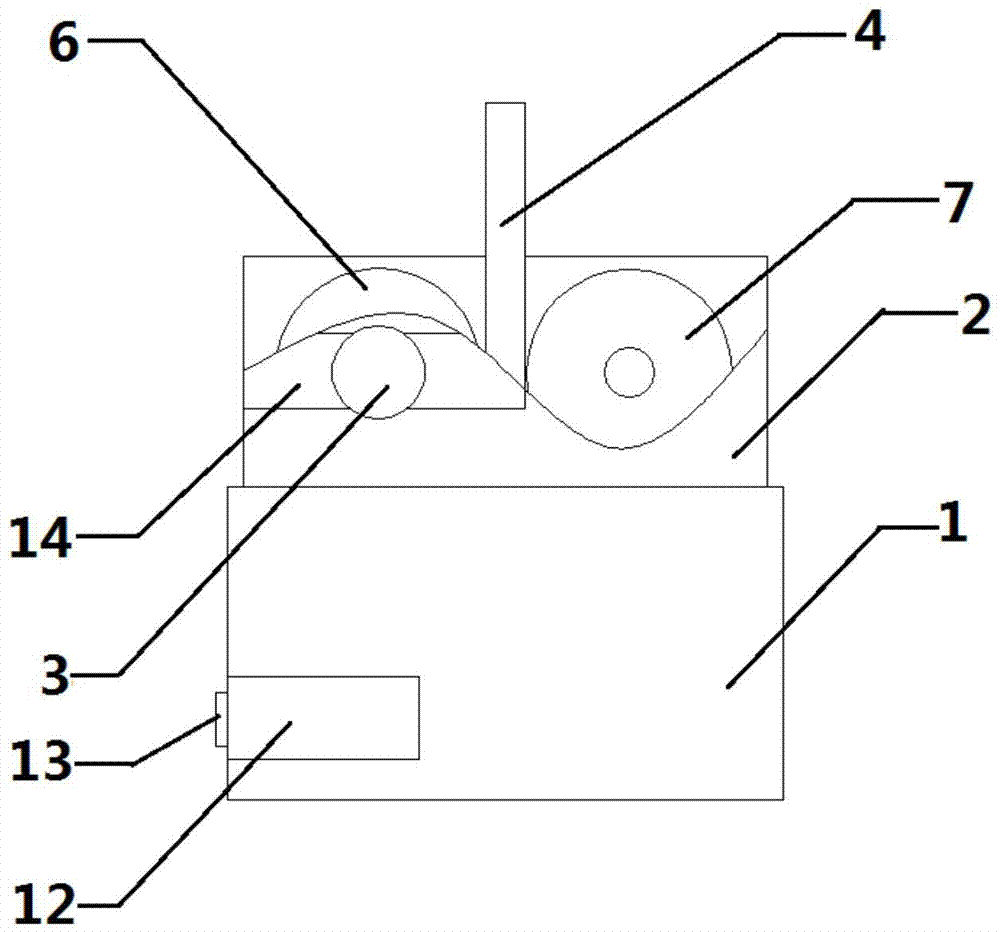

[0010] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0011] A kind of rubber plasticating machine as shown in the accompanying drawing, comprises workbench 1, and described workbench 1 top surface both sides are respectively provided with a roller frame 2 any described roller frame 2 is all provided with slideways 14, two slideways A movable pressure roller 6 is arranged between the roads 14, and the movable pressure roller 6 is connected with any slideway through a locking hand wheel 3; a fixed pressure roller 7 is arranged between the roller frames 2, and the fixed pressure roller 7 is connected with the movable pressure roller. 6 are parallel and at the same height, and the inner walls of the fixed pressure roller 7 and the movable pressure roller 6 are all provided with a heating layer 8; the two sides of the top surface of the workbench 1 are respectively provided with a bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com