Antiseptic and mildew-proof agent for wooden and/or bamboo product and application thereof

A technology for anti-corrosion and anti-fungal agent and bamboo products, which is applied in the direction of wood treatment, impregnating wood, manufacturing tools, etc. problems, to achieve the effect of improving the use value and safety of use, inhibiting bacteriostasis and inhibiting the growth of microorganisms, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of anti-mold preservative for wood and bamboo products

[0030] Percentage of each component: sodium benzoate 0.05%, potassium sorbate 0.25%, sodium ethyl p-hydroxybenzoate 0.03%, the balance of water. Dissolve the ingredients in water, stir well and mix well.

[0031] 2. Sample processing

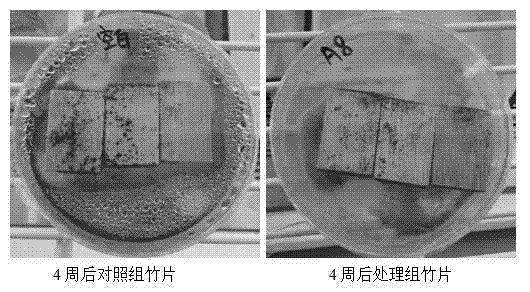

[0032] The moso bamboo was sawed into 30mm×20mm×5mm bamboo slices, and randomly divided into control group and treatment group, with three pieces in each group. The treatment group was completely immersed in the above-mentioned antiseptic, antiseptic and antifungal agent solution for 8 hours, and the control group was immersed in sterile water for 8 hours, taken out and drained, and then the bamboo slices were placed in a dry sterile culture dish.

Embodiment 2

[0034] 1. Preparation of anti-mold preservative for wood and bamboo products

[0035] Percentage of each component: sodium benzoate 0.15%, potassium sorbate 0.25%, sodium ethyl p-hydroxybenzoate 0.05%, the balance of water. Dissolve the ingredients in water, stir well and mix well.

[0036] 2. Sample processing

[0037]The poplar wood was sawn into 20mm×20mm×20mm specimens, randomly divided into control group and treatment group, with three pieces in each group. The wooden blocks were completely immersed in the above-mentioned antiseptic and antifungal agent solution for 12 hours, and the control group was immersed in sterile water for 12 hours. After taking it out, drain it, and then put the wooden blocks in a dry sterile petri dish.

Embodiment 3

[0039] 1. Preparation of anti-mold preservative for wood and bamboo products

[0040] Percentage of each component: sodium benzoate 0.10%, potassium sorbate 0.10%, sodium ethyl p-hydroxybenzoate 0.015%, the balance of water. Dissolve the ingredients in water, stir well and mix well.

[0041] 2. Sample processing

[0042] Saw the moso bamboo into 30mm×20mm×5mm specimens, and randomly divided them into control group, spraying group and dipping group, with two pieces in each group. The spraying group uses spray equipment to evenly spray the above antiseptic and antifungal agent solution on the surface of bamboo; the dipping group is to immerse the test piece in the above antiseptic and antifungal agent solution for 8 hours, and then place the bamboo slices in a dry sterile petri dish. ; The control group was immersed in sterile water for 8 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com