Micro-nano copper particle filled Sn based soldering paste for high-temperature packaging of electronic module and preparation method of soldering paste

A technology of micro-nano particles and electronic modules, applied in the field of materials, can solve problems affecting the reliability of solder joints, achieve huge development potential and application prospects, enhance solder joint performance, and improve high-temperature service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

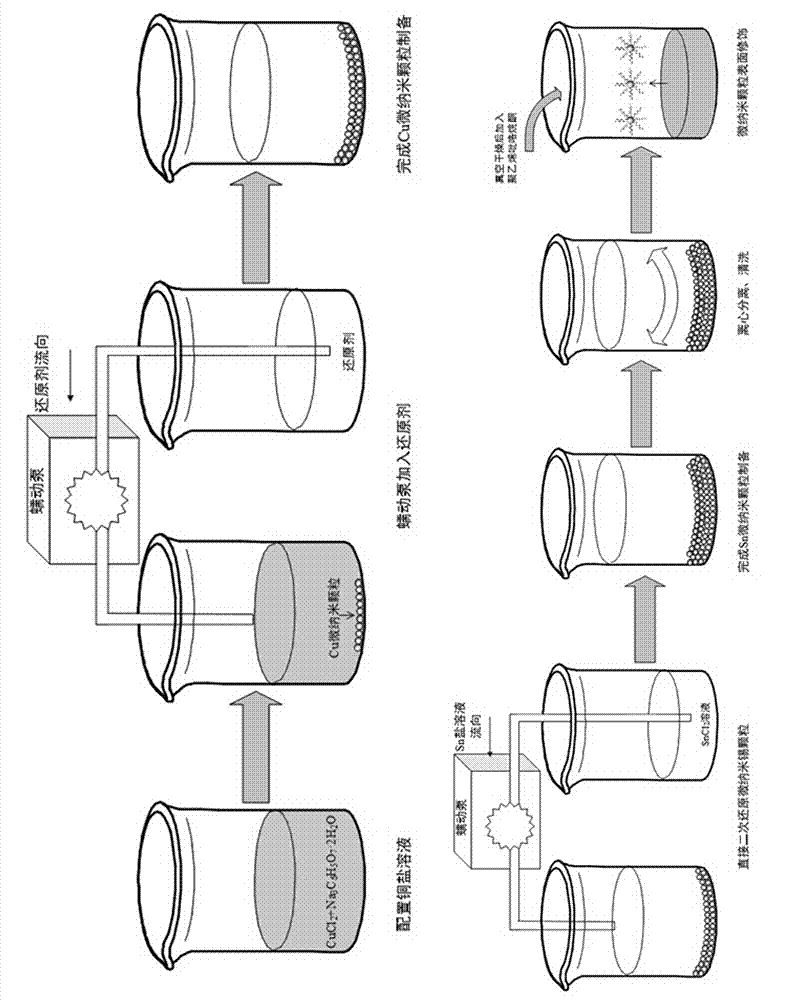

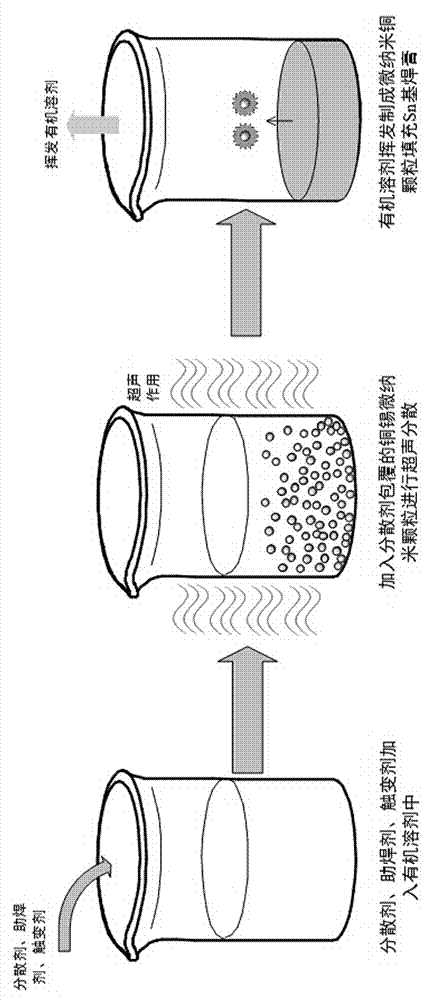

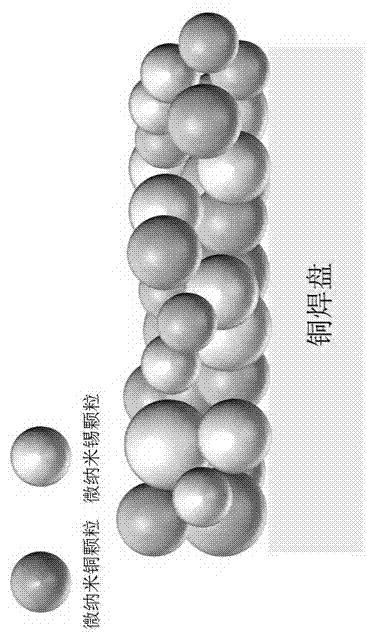

[0033] Specific implementation mode one: as Figure 1-3 As shown, this embodiment describes the present invention in detail in conjunction with the specific method for preparing Sn-based solder paste filled with micro-nano copper particles with a copper-tin ratio of 6:5:

[0034] Step 1: React CuCl 2 and complexing agent sodium citrate placed in a reaction beaker, dissolved in ethanol solution.

[0035] Step 2: Prepare a reducing agent solution, the reducing agent is sodium borohydride or hydrazine hydrate, and the ratio of the amount of the reducing agent to the amount of copper and tin is 5:1.

[0036] Step 3: Use a peristaltic pump to add the reducing agent solution to CuCl 2 In the solution, the adding rate is 0.5~1mL / s, and stand for 5 minutes after the reaction is complete.

[0037] Step 4: Weigh the corresponding SnCl according to the copper-tin ratio of 6:5 2 Drugs, and dissolved in ethanol solution.

[0038] Step 5: Use a peristaltic pump to transfer SnCl 2 The ...

specific Embodiment approach 2

[0044] Specific embodiment two: This embodiment describes the present invention in detail in conjunction with the specific method for preparing Sn-based solder paste filled with micro-nano copper particles with a copper-to-tin ratio of 3:1:

[0045] Step 1: React CuSO 4 and complexing agent citric acid are placed in a reaction beaker and dissolved in acetone solution.

[0046] Step 2: Configure the reducing agent solution, the reducing agent is sodium borohydride or TiCl 4 , the ratio of the amount of reducing agent to the amount of copper and tin is 10:1.

[0047] Step 3: Add the reducing agent solution to CuSO using a peristaltic pump 4 In the solution, the rate of addition is 2~4mL / s, and the reaction is completed and left to stand for 10 minutes.

[0048] Step 4: Weigh the corresponding SnSO according to the copper-tin ratio of 3:1 4 Drugs, and dissolved in acetone solution.

[0049] Step 5: Use a peristaltic pump to transfer SnSO 4 The solution is added to the solut...

specific Embodiment approach 3

[0055] Specific embodiment three: This embodiment describes the present invention in detail in conjunction with a specific method for preparing Sn-based solder paste filled with micro-nano copper particles with a copper-tin ratio of 2:1:

[0056] Step 1: React CuSO 4 and complexing agent citric acid are placed in a reaction beaker and dissolved in acetone solution.

[0057] Step 2: Configure the reducing agent solution, the reducing agent is selected as hydrazine hydrate or TiCl 4 , the ratio of the amount of reducing agent to the amount of copper and tin is 10:1.

[0058] Step 3: Add the reducing agent solution to CuSO using a peristaltic pump 4 In the solution, the rate of addition is 1~3mL / s, and after the reaction is complete, let it stand for 5 minutes.

[0059] Step 4: Weigh the corresponding SnSO according to the copper-tin ratio of 2:1 4 Drugs, and dissolved in acetone solution.

[0060] Step 5: Use a peristaltic pump to transfer SnSO 4 The solution is added to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com