Preparation method and application of Cu-ZSM-5 doped Zr and Sr composite catalyst

A technology of cu-zsm-5, 1.cu-zsm-5, applied in the field of preparation and application of Cu-ZSM-5 doped Zr and Sr composite catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

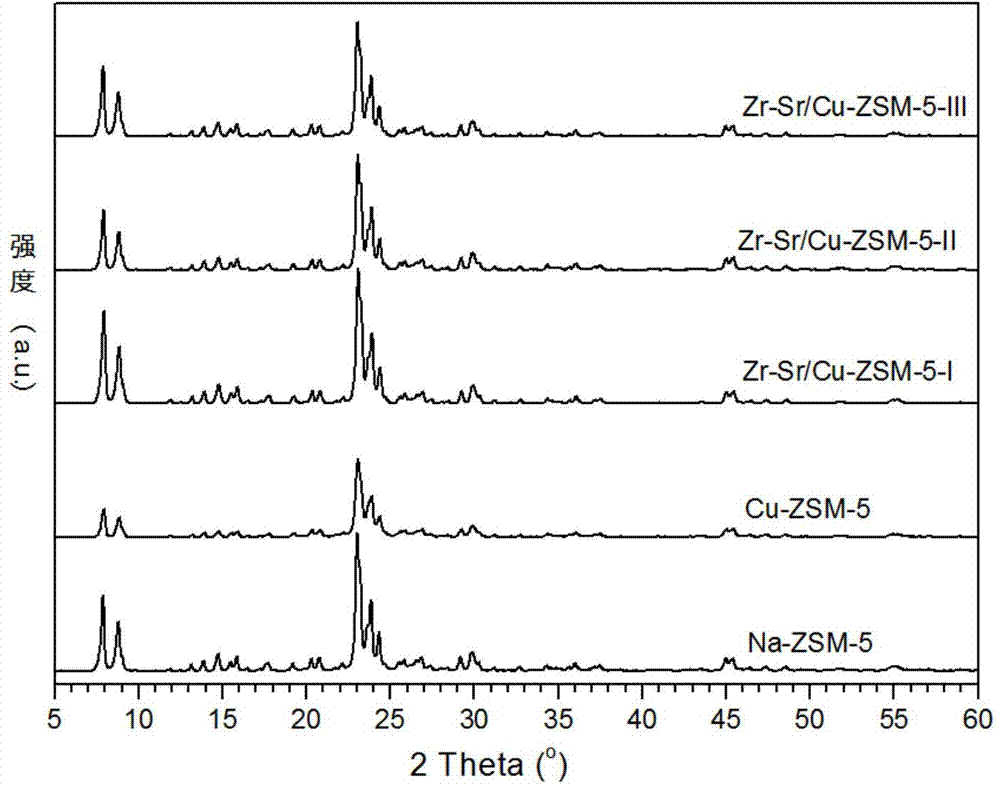

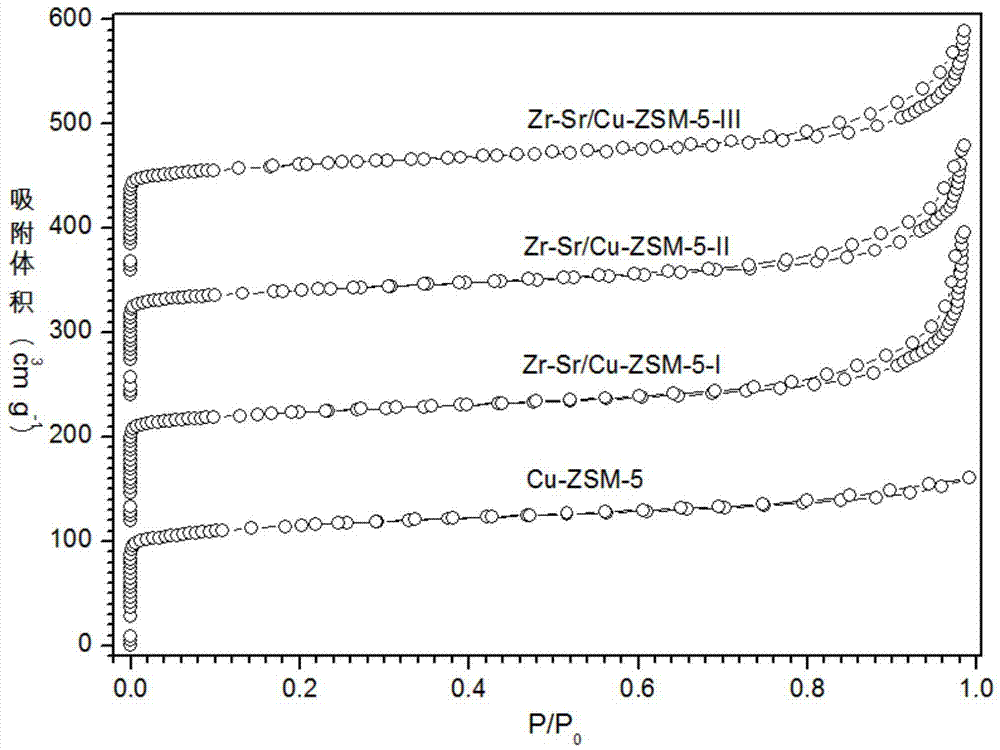

[0023] (1) Combine Na-ZSM-5 molecular sieve with a silicon-to-aluminum ratio of 20mol:1mol and 0.1mol.L -1 NH 4 The Cl solution was ion-exchanged at 60℃ for 2h, in which Na-ZSM-5 molecular sieve and NH 4 The ratio of Cl is 100g:0.6mol, the above process is repeated once, filtering, washing 3 times, and drying at 120°C for 18h to obtain NH 4 -ZSM-5 molecular sieve; the obtained NH 4 -ZSM-5 molecular sieve is added to 0.01mol.L -1 Cu(OAc) 2 Medium, 60℃ ion exchange 2h, where NH 4 -ZSM-5 molecular sieve and Cu(OAc) 2 The ratio is 100g:0.03mol. According to the above process, repeat once, filter, wash 3 times, and dry at 120°C for 18 hours to obtain Cu-ZSM-5 precursor. Then evenly mix 0.001mol.L -1 Zr(NO 3 ) 4 Solution and 0.001mol.L -1 Sr(NO 3 ) 2 Solution in which Zr(NO 3 ) 4 With Sr(NO 3 ) 2 The ratio is 1:1, the Cu-ZSM-5 precursor prepared above is added to the above mixed solution, and the immersion method is used for 24h. Among them, the Cu-ZSM-5 precursor and Zr(NO 3 ) 4 The ra...

Embodiment 2

[0026] (1) Na-ZSM-5 molecular sieve with a silicon-to-aluminum ratio of 23mol:1mol and 0.3mol.L -1 NH 4 The Cl solution was ion-exchanged at 70℃ for 3h, in which Na-ZSM-5 molecular sieve and NH 4 The ratio of Cl is 100g:2.0mol, the above process is repeated twice, filtering, washing 4 times, and drying at 130°C for 20h to obtain NH 4 -ZSM-5 molecular sieve; the obtained NH 4 -ZSM-5 molecular sieve is added to 0.015mol.L -1 Cu(OAc) 2 Medium, 780℃ ion exchange 3h, where NH 4 -ZSM-5 molecular sieve and Cu(OAc) 2 The ratio is 100g:0.05mol. According to the above process, repeat 2 times, filter, wash 4 times, and dry at 130°C for 20 hours to obtain Cu-ZSM-5 precursor. Then mix evenly 0.002mol.L -1 Zr(NO 3 ) 4 Solution and 0.002mol.L -1 Sr(NO 3 ) 2 Solution in which Zr(NO 3 ) 4 With Sr(NO 3 ) 2 The ratio is 1:1, the Cu-ZSM-5 precursor prepared above is added to the above mixed solution, and the immersion method is used for 36h. Among them, the Cu-ZSM-5 precursor and Zr(NO 3 ) 4 The rati...

Embodiment 3

[0029] (1) Combine Na-ZSM-5 molecular sieve with a silicon-to-aluminum ratio of 25mol:1mol and 0.5mol.L -1 NH 4 The Cl solution was ion-exchanged at 80℃ for 5h, in which Na-ZSM-5 molecular sieve and NH 4 The ratio of Cl is 100g:3.0mol, the above process is repeated 3 times, filtered, washed 5 times, and dried at 40°C for 24h to obtain NH 4 -ZSM-5 molecular sieve; the obtained NH 4 -ZSM-5 molecular sieve is added to 0.024mol.L -1 Cu(OAc) 2 Medium, 80℃ ion exchange for 5h, where NH 4 -ZSM-5 molecular sieve and Cu(OAc) 2 The ratio is 100g:0.072mol. According to the above process, repeat 3 times, filter, wash 5 times, and dry at 140°C for 24 hours to obtain Cu-ZSM-5 precursor. Then mix evenly 0.003mol.L -1 Zr(NO 3 ) 4 Solution and 0.003mol.L -1 Sr(NO 3 ) 2 Solution in which Zr(NO 3 ) 4 With Sr(NO 3 ) 2 The ratio is 1:1, the Cu-ZSM-5 precursor prepared above is added to the above mixed solution, and the impregnation method is used for 48h. Among them, the Cu-ZSM-5 precursor and Zr(NO 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com