Pressure swing adsorption gas separation method for recycling displacement waste gas and directly-discharged gas

A pressure swing adsorption and gas separation technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of limited implementation scope, high investment, complex process, etc., to reduce material consumption, energy consumption, investment Less and simpler process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

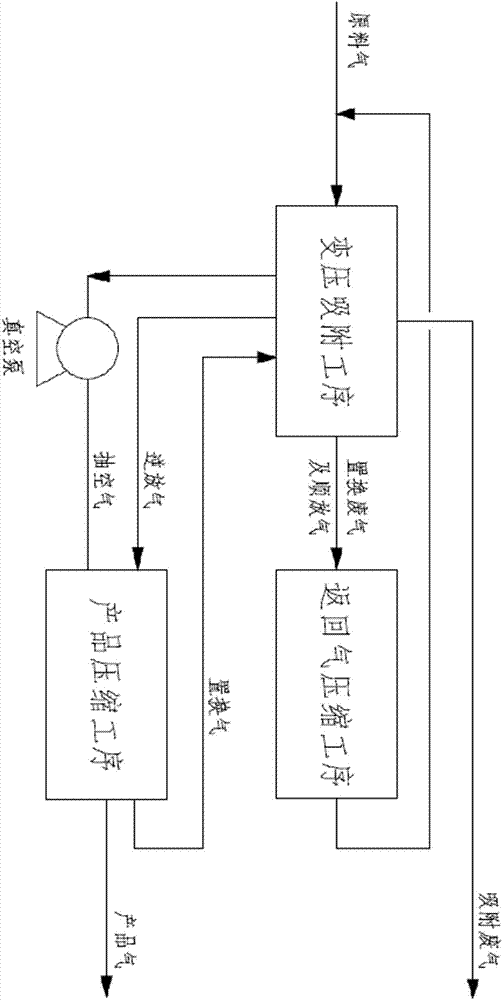

Method used

Image

Examples

Embodiment 1

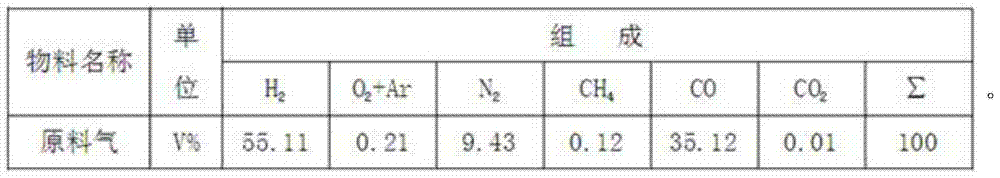

[0034] This embodiment is a pressure swing adsorption separation device for separating and recovering carbon monoxide from water gas, and the flow rate of fresh raw gas is 500Nm 3 / h, the adsorption pressure is 0.25MPa gauge pressure, the feed gas temperature is 40°C, and the fresh feed gas composition is shown in Table 1:

[0035] Table 1 Composition of fresh feed gas

[0036]

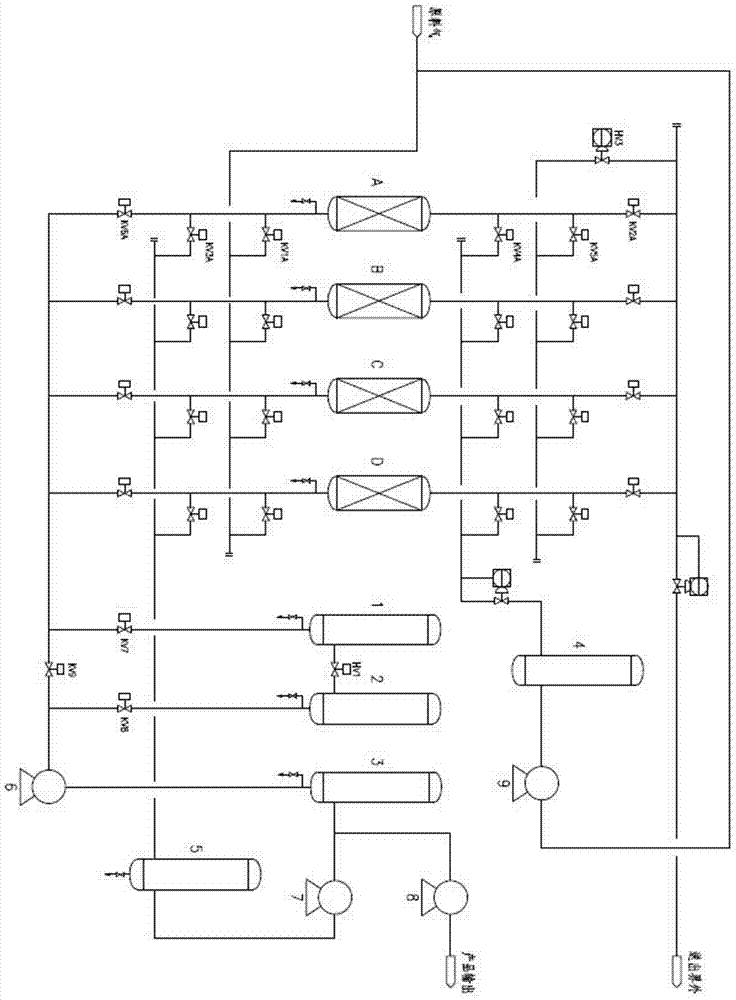

[0037] The volume of the adsorption tower of the pressure swing adsorption device in this embodiment is 5m 3 , where the loaded adsorbents are molecular sieve, activated carbon, and activated alumina from top to bottom, and the filling height ratio is 4:1:1. The device consists of 4 adsorption towers, 1 reverse tank, 1 vacuum tank, 3 vacuum pumps, 1 displacement waste gas buffer tank, 1 product mixing tank, 1 displacement gas buffer tank, 1 displacement gas compressor, 1 It is formed by connecting one product air compressor, one return air compressor and corresponding pipelines and program-contro...

Embodiment 2

[0055] This embodiment is a coke oven gas enrichment methane device after conversion and removal of carbon dioxide, and the coke oven gas flow rate is 42000Nm 3 / h, the adsorption pressure is 0.95MPa gauge pressure, the feed gas temperature is 30°C, and the fresh feed gas composition is shown in Table 4:

[0056] Table 4 Composition of Fresh Raw Gas

[0057]

[0058] The volume of adsorption tower is 90m in the present embodiment 3 The adsorbents filled in it are mainly activated alumina and activated carbon. The device consists of 8 adsorption towers, 2 reverse tanks, 2 product mixing tanks, 1 replacement waste gas buffer tank, 1 intermediate tank, and 1 replacement gas The buffer tank, vacuum pump unit, product gas compressor, displacement gas compressor, return gas compressor and corresponding pipelines and program-controlled valves are connected. Each adsorption tower sequentially undergoes adsorption A, first-average drop E1D, second-average drop E2D, third-average d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com