Absorbable magnetic clay musk and preparation method thereof

A mask mud and magnetic technology, applied in the field of skin care products, can solve the problems of secondary absorption of products, strong stickiness of mask mud, complicated cleaning work, etc., to achieve stable product performance, brighten skin tone, and reduce skin fine lines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

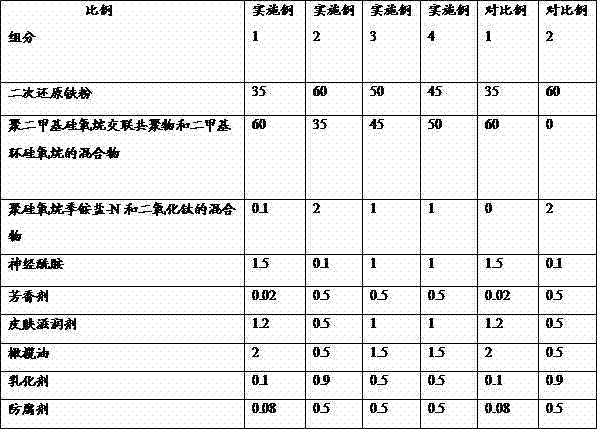

[0049] Step 1) According to the component formula and weight ratio shown in Table 1, weigh each raw material component, wherein polydimethylsiloxane cross-linked copolymer and dimethylcyclosiloxane are mixed in a ratio of 6:4 Mass ratio is mixed, polysiloxane quaternary ammonium salt-N and titanium dioxide are mixed with the mass ratio of 1.5:8.5;

[0050] Step 2) Add the weighed mixture of polysiloxane quaternary ammonium salt-N and titanium dioxide, skin moisturizer, olive oil, and preservative into the container, mix and stir evenly, and heat up to 78°C-95°C while stirring;

[0051] Step 3) Add emulsifier and ceramide 3, and keep the temperature constant for 10-30 minutes while stirring;

[0052] Step 4) Cool down to 55°C-75°C while stirring, add the mixture of polydimethylsiloxane cross-linked copolymer and dimethylcyclosiloxane, and stir evenly;

[0053] Step 5) Stir to lower the temperature below 45°C, add secondary reduced iron powder and fragrance, mix and stir evenly...

Embodiment 2

[0056] Step 1) According to the component formula and weight ratio shown in Table 1, weigh each raw material component, wherein polydimethylsiloxane cross-linked copolymer and dimethylcyclosiloxane are mixed at a ratio of 8:2 Mass ratio is mixed, polysiloxane quaternary ammonium salt-N and titanium dioxide are mixed with the mass ratio of 3.5:6.5;

[0057] Step 2) Add the weighed mixture of polysiloxane quaternary ammonium salt-N and titanium dioxide, skin moisturizer, olive oil, and preservative into the container, mix and stir evenly, and heat up to 78°C-95°C while stirring;

[0058] Step 3) Add emulsifier and ceramide 3, and keep the temperature constant for 10-30 minutes while stirring;

[0059] Step 4) Cool down to 55°C-75°C while stirring, add the mixture of polydimethylsiloxane cross-linked copolymer and dimethylcyclosiloxane, and stir evenly;

[0060] Step 5) Stir to lower the temperature below 45°C, add secondary reduced iron powder and fragrance, mix and stir evenly...

Embodiment 3-4

[0063] Step 1) According to the component formula and weight ratio shown in Table 1, weigh each raw material component, wherein polydimethylsiloxane cross-linked copolymer and dimethylcyclosiloxane are mixed at a ratio of 8:2 Mass ratio is mixed, polysiloxane quaternary ammonium salt-N and titanium dioxide are mixed with the mass ratio of 2:8;

[0064] Step 2) Add the weighed mixture of polysiloxane quaternary ammonium salt-N and titanium dioxide, skin moisturizer, olive oil, and preservative into the container, mix and stir evenly, and heat up to 78°C-95°C while stirring;

[0065] Step 3) Add emulsifier and ceramide 3, and keep the temperature constant for 10-30 minutes while stirring;

[0066] Step 4) Cool down to 55°C-75°C while stirring, add the mixture of polydimethylsiloxane cross-linked copolymer and dimethylcyclosiloxane, and stir evenly;

[0067] Step 5) Stir to lower the temperature below 45°C, add secondary reduced iron powder and fragrance, mix and stir evenly;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com