A Multilayer Substrate Integrated Waveguide Array Antenna

A substrate-integrated waveguide and array antenna technology, which is applied in antennas, antenna arrays, waveguide horns, etc., can solve the problems that the antenna cannot meet the wide-band working requirements, the feed network is complicated, and the unfavorable high efficiency, etc., so as to facilitate the miniaturization of the system and integrated applications, high efficiency, and the effect of good impedance matching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with accompanying drawing:

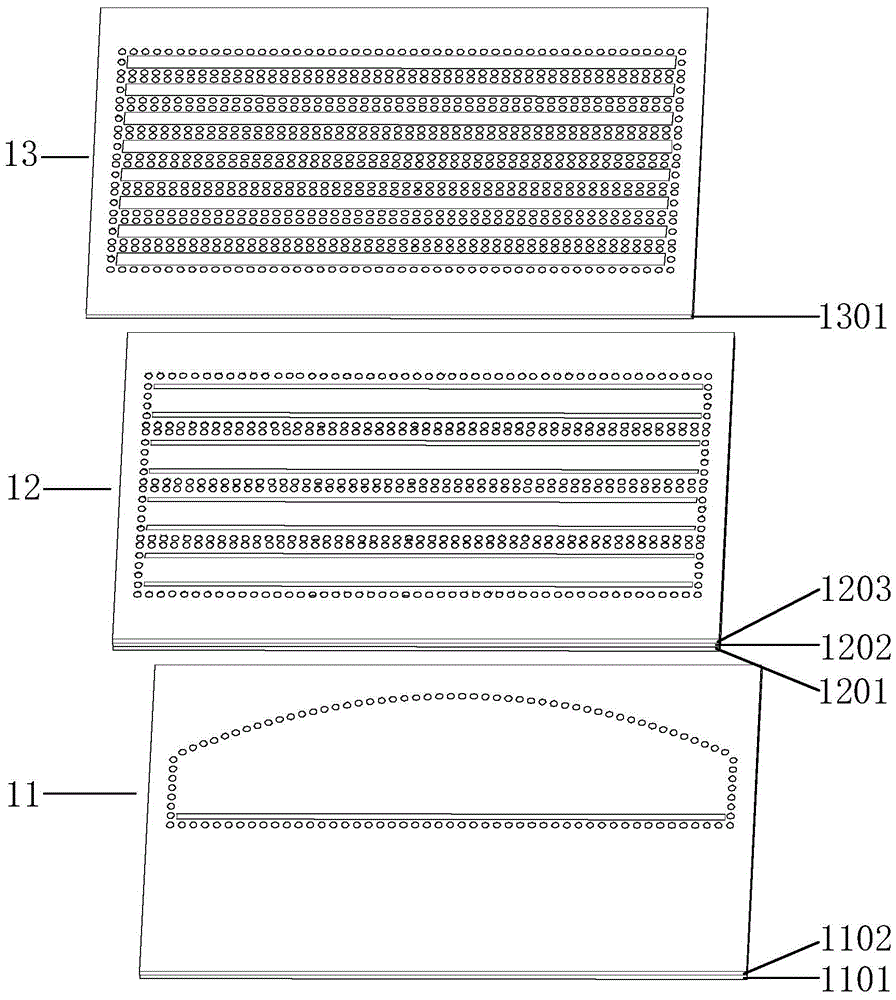

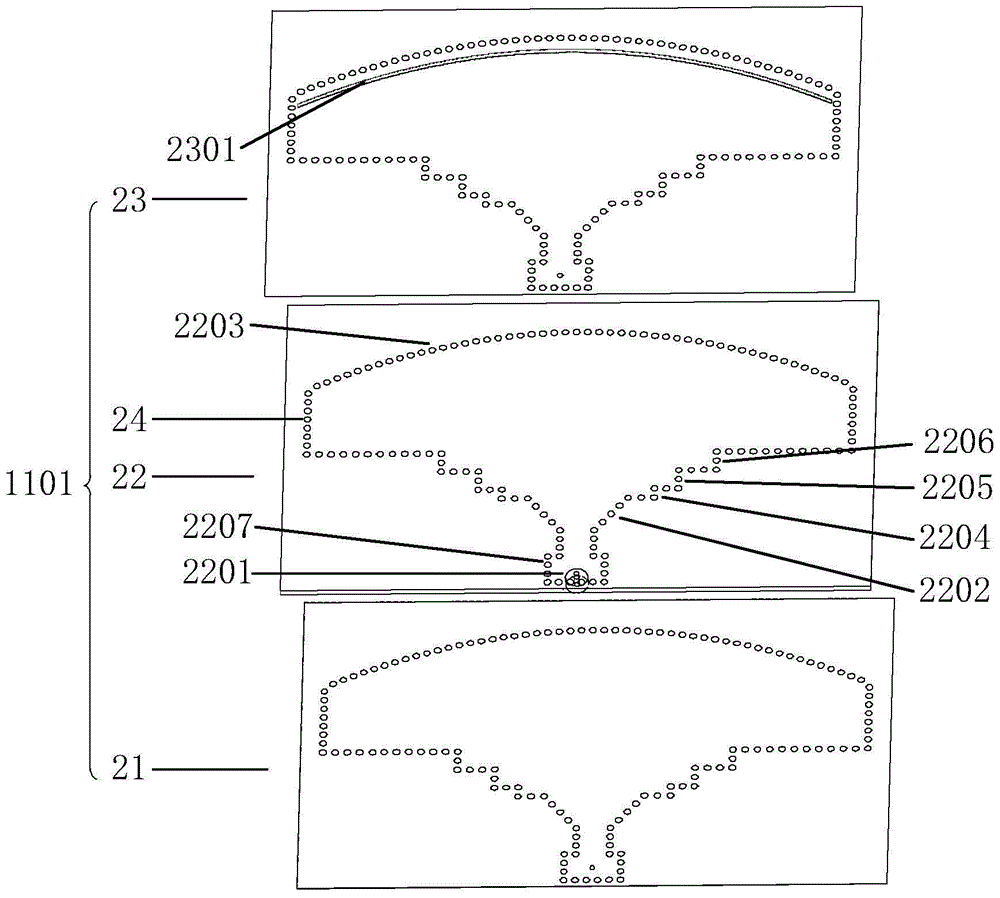

[0041] see Figure 1-Figure 8, a multi-layer substrate integrated waveguide array antenna of the present invention includes a plane wave excitation layer 11, a power divider layer 12 and an antenna radiation layer 13 stacked sequentially from bottom to top; the plane wave excitation layer 11 includes a layer stacked from bottom to top No. 1 lower substrate integrated waveguide 1101 and No. 1 upper substrate integrated waveguide 1102; No. 1 lower substrate integrated waveguide 1101 includes a lower dielectric substrate 22, a lower metallized through hole 24 located on the lower dielectric substrate 22, and a lower dielectric substrate attached to the lower dielectric substrate 22. The lower copper clad layer 21 and the upper copper clad layer 23 on the upper and lower surfaces are provided with a coaxial feed port 2201, a parabolic parabolic substrate integrated wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com