Power cell heat management device and method

A power battery and thermal management technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as the inability to effectively control the battery temperature, and achieve a good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

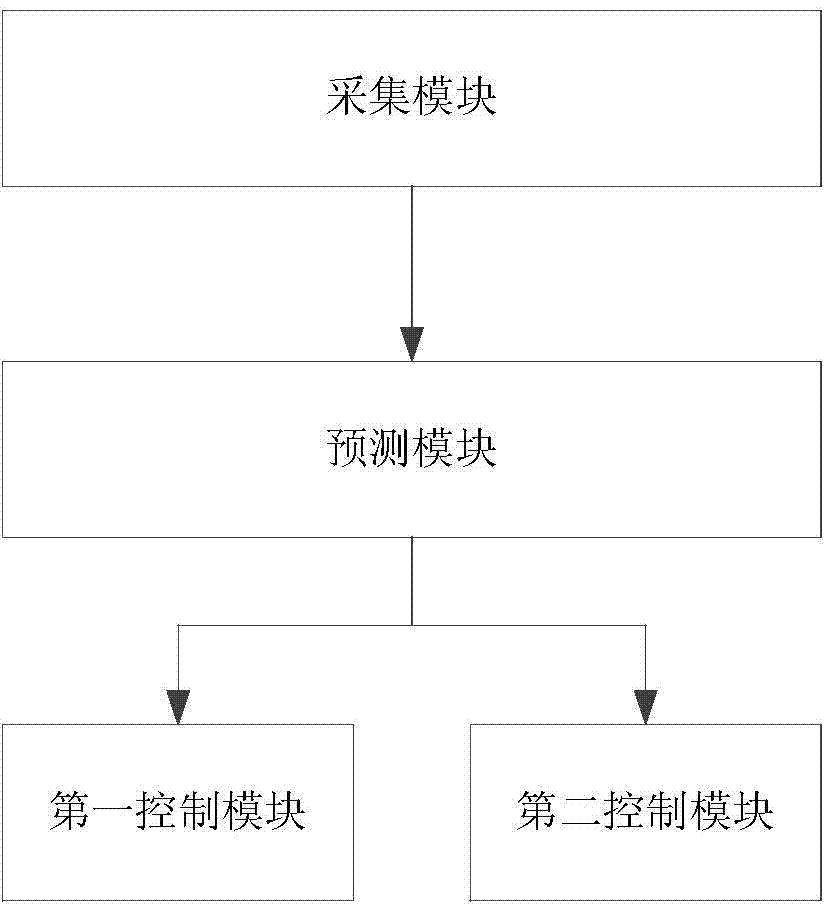

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a power battery thermal management device, including:

[0038] The acquisition module is used to collect the current value output by the battery, the battery temperature value, and the ambient temperature value outside the battery in real time;

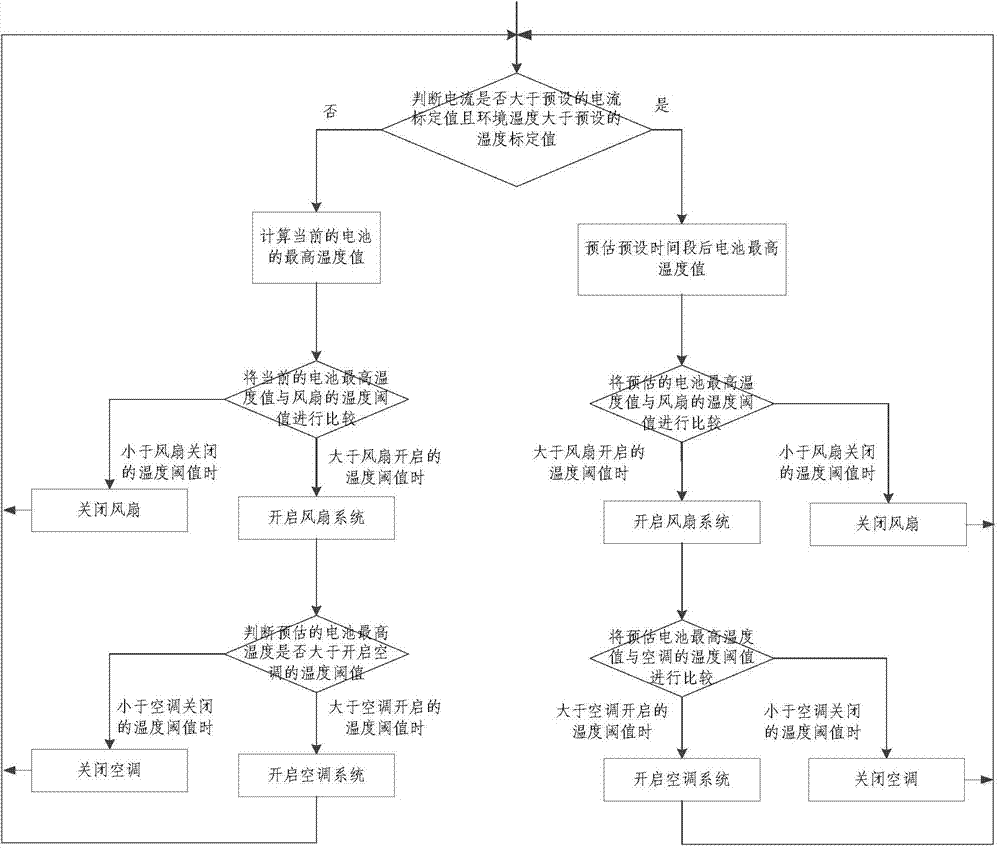

[0039] A prediction module, configured to start a first control module when the current value is higher than the preset current calibration value and the ambient temperature value is higher than the preset ambient temperature calibration value; when the When the current value is lower than the preset current calibration value and / or the ambient temperature value is lower than the preset ambient temperature calibration value, start the second control module;

[0040] The first control module, by predicting the state of the battery after the preset time period, according to the thermal model of the battery, estimates the maximum temperature value of the ...

Embodiment 2

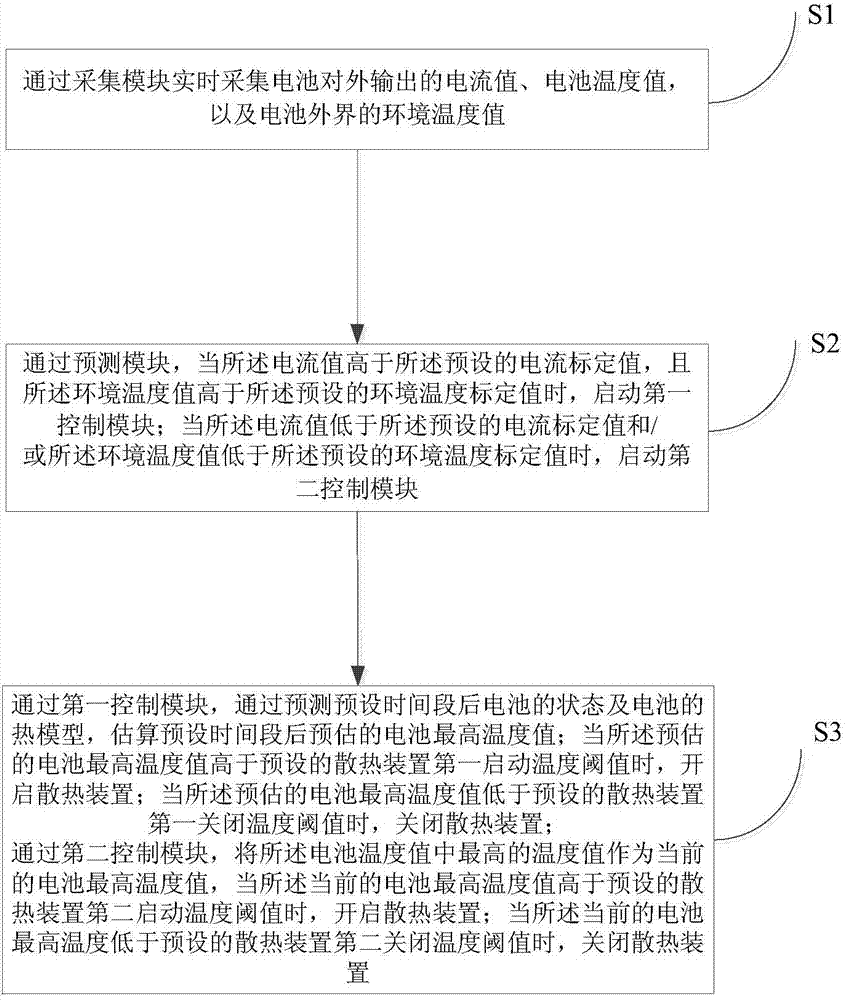

[0051] Such as figure 2 As shown, the embodiment of the present invention also provides a power battery thermal management method, including:

[0052] S1. Collect the current value output by the battery, the temperature value of the battery, and the ambient temperature value outside the battery in real time through the acquisition module;

[0053] S2. Through the prediction module, when the current value is higher than the preset current calibration value, and the ambient temperature value is higher than the preset ambient temperature calibration value, start the first control module; when the When the current value is lower than the preset current calibration value and / or the ambient temperature value is lower than the preset ambient temperature calibration value, start the second control module;

[0054] S3. Through the first control module, by predicting the state of the battery after the preset time period, and according to the thermal model of the battery, estimate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com