Drive control integrated circuit special for microwave oven

A drive circuit and drive control technology, which is applied in the general control system, program control, computer control, etc., can solve the problems of large PCB circuit board size, high processing defect rate of system design cost, and large number of peripheral components. The effect of small PCB circuit board size, reduced system design cost and processing defect rate, and reduced number of peripheral components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with the best embodiment.

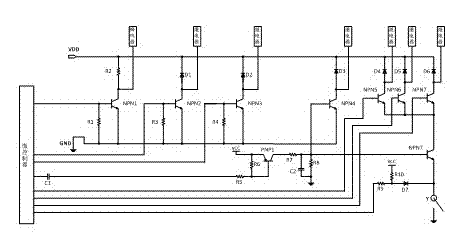

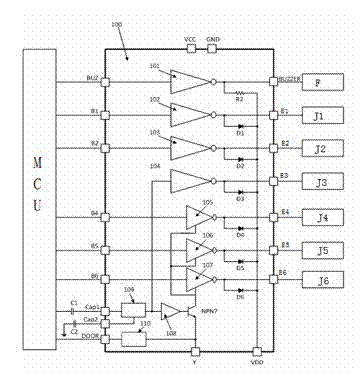

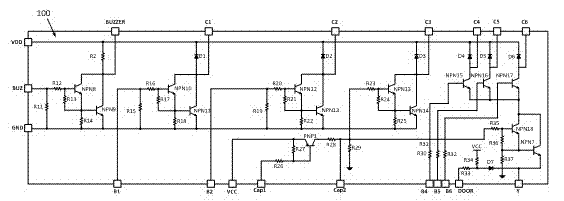

[0010] like figure 2 As shown, a microwave oven dedicated drive control integrated circuit is characterized in that it is composed of a microcontroller MCU, an integrated chip 100, a buzzer F, and six relays; the integrated chip 100 includes a buzzer drive circuit 101, six relays Drive circuit, triode NPN7, triode drive circuit 108, single-chip microcomputer detection circuit 109 and gate signal detection circuit 110; The output port of microcontroller MCU is respectively connected buzzer drive circuit 101, six relay drive circuits; Buzzer inside integrated chip 100 Buzzer drive circuit 101, six relay drive circuits are respectively connected to buzzer F, six relays; integrated chip 100 also includes single-chip microcomputer detection circuit 109, gate signal detection circuit 110, and single-chip microcomputer detection circuit 109 output terminals are respectively connected to triod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com