Three-layer type rotary drum dryer

A dryer and rotary drum technology, applied in non-progressive dryers, dryers, drying chambers/containers, etc., can solve the problems of poor drying performance and incomplete drying of materials, and achieve ideal results and drying. The effect of better performance and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

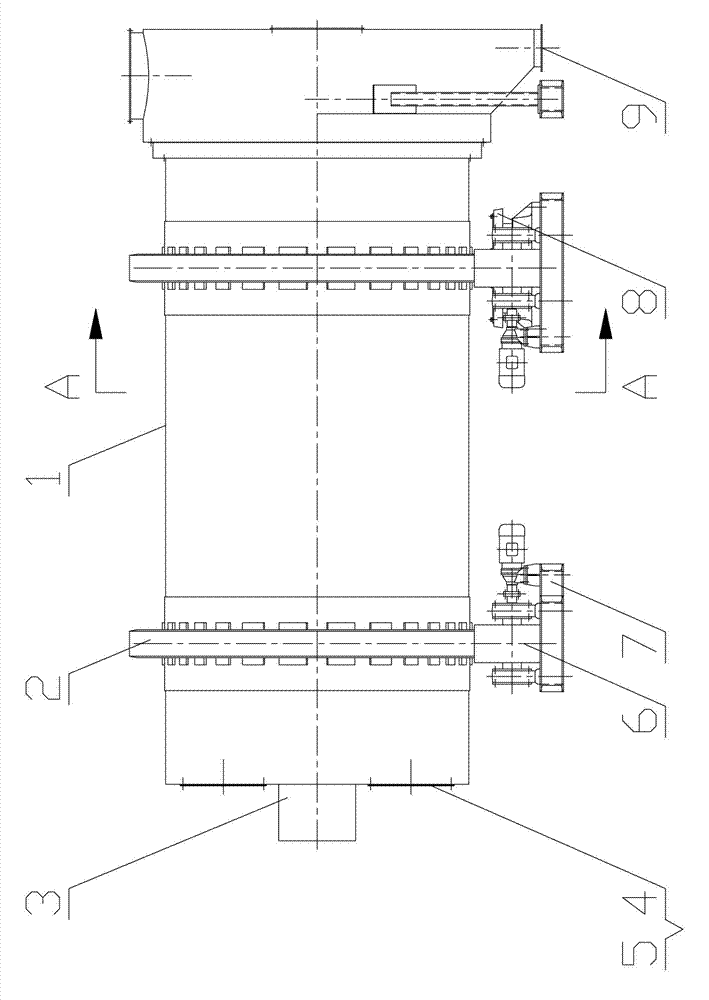

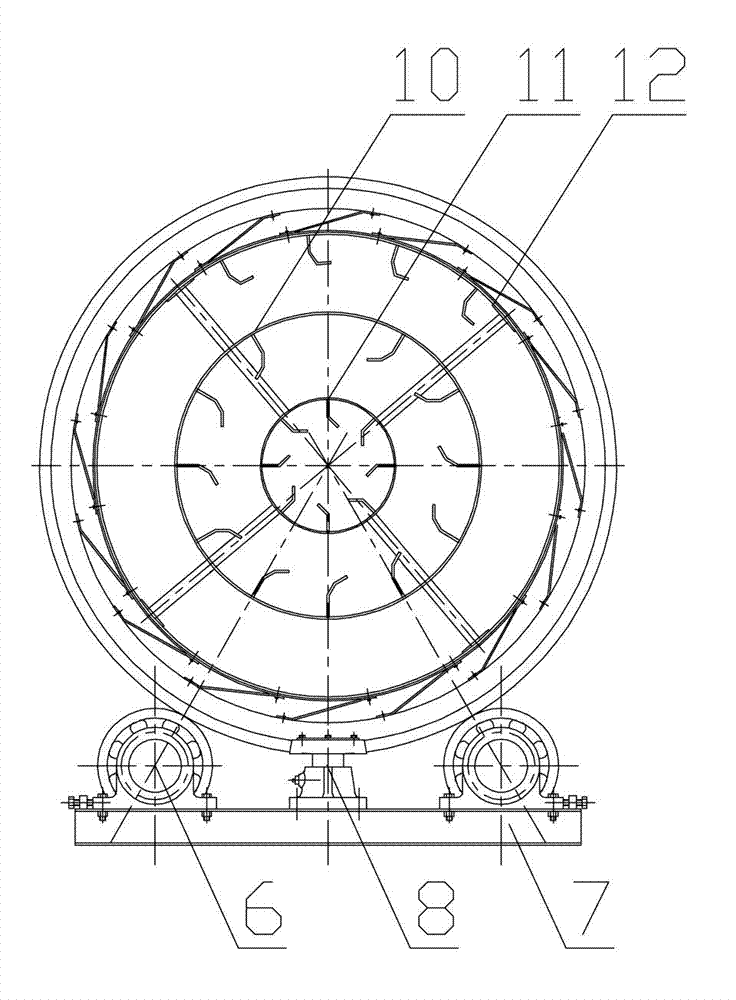

[0011] see figure 1 , the present invention has cylinder body 1, and cylinder body 1 is equipped with two big roller rings 2, and the bottom of big roller rings 2 is equipped with supporting roller assembly 6, and supporting roller assembly 6 is fixed on the base 7; There is a feed port 3 and a discharge port 9, and the feed port 3 is equipped with a hole cover 4 and a heat-resistant asbestos pad 5; in particular: the cylinder 1 is composed of an inner cylinder 11, a middle cylinder 10, and an outer cylinder 12 Composed of three layers.

[0012] In this embodiment, the base 7 is also equipped with a retaining wheel assembly 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com