Beet pectin and extraction method thereof

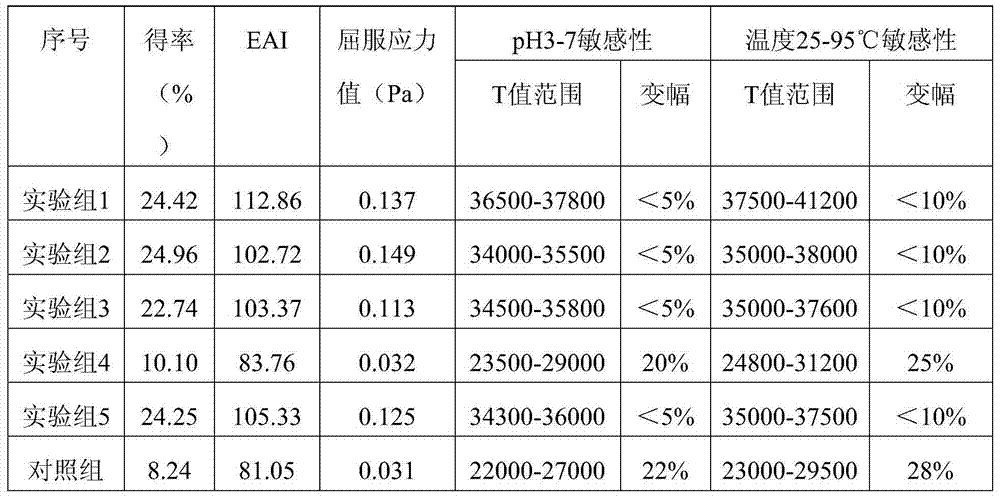

An extraction method and beet pectin technology are applied in the field of sugar beet pectin and its extraction, which can solve the problems of low pectin yield, poor emulsion turbidity and purity, difficult to satisfy pectin yield stress, etc. Turbidity, difficult separation, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The sugar beet pectin described in the present embodiment is extracted through the following steps:

[0036] (1) Take an appropriate amount of dry sugar beet meal and crush it, and pass it through a 60-mesh sieve;

[0037] (2) Add 50g of powder into 1000mL of water, adjust the pH value to 1 with 12mol / L concentrated hydrochloric acid, and stir at 90°C for 5h;

[0038] (3) Cool the obtained extract to a temperature lower than 40°C, and adjust the pH to about 4.5 with 25% concentrated ammonia water;

[0039] (4) Then use suction filtration to separate the material and liquid, collect the supernatant and measure its volume, then pour the supernatant into 2 times the volume of absolute ethanol in a trickle, and let it stand for 1 hour to make the pectin Precipitation is complete;

[0040] (5) Wash the pectin twice with absolute ethanol, dry it in a blast drying oven at 50°C for 5 hours, crush the obtained beet pectin with a grinder, pack it into bags and seal it up.

Embodiment 2

[0042] The sugar beet pectin described in the present embodiment is extracted through the following steps:

[0043] (1) Take an appropriate amount of dry beet dregs and crush them, and pass through a 40-mesh sieve;

[0044] (2) Add 50g of powder into 750mL of water, adjust the pH value to 1.5 with 10mol / L concentrated hydrochloric acid, and stir at 96.8°C for 3h;

[0045] (3) Cool the obtained extract to room temperature, and adjust the pH to about 4 with 30% concentrated ammonia water;

[0046] (4) Then use suction filtration to separate the material and liquid, collect the supernatant and measure its volume, then pour the supernatant into 1.5 times the volume of absolute ethanol in a trickle, and let it stand for 1 hour to make the pectin Precipitation is complete;

[0047] (5) Wash the pectin twice with absolute ethanol, dry it in a blast drying oven at 50°C for 5 hours, crush the obtained beet pectin with a grinder, pack it into bags and seal it up.

Embodiment 3

[0049] The sugar beet pectin described in the present embodiment is extracted through the following steps:

[0050] (1) Take an appropriate amount of dry beet dregs and crush them, and pass through a 100-mesh sieve;

[0051] (2) Add 50g of powder into 1250mL of water, adjust the pH value to 0.5 with 15mol / L concentrated hydrochloric acid, and stir at 90°C for 2h;

[0052] (3) Cool the obtained extract until the temperature is lower than 40°C, and adjust the pH to about 5 with 25% concentrated ammonia water;

[0053] (4) Then use suction filtration to separate the material and liquid, collect the supernatant and measure its volume, then pour the supernatant into 2 times the volume of absolute ethanol in a trickle, and let it stand for 1 hour to make the pectin Precipitation is complete;

[0054] (5) Wash the pectin twice with absolute ethanol, dry it in a blast drying oven at 50°C for 5 hours, crush the obtained beet pectin with a grinder, pack it into bags and seal it up.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com