Preparation method of glycosylated surfactant

A surfactant and sugar-based technology, applied in the field of preparation of sugar-based active agents, to achieve good application prospects, high surface activity and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

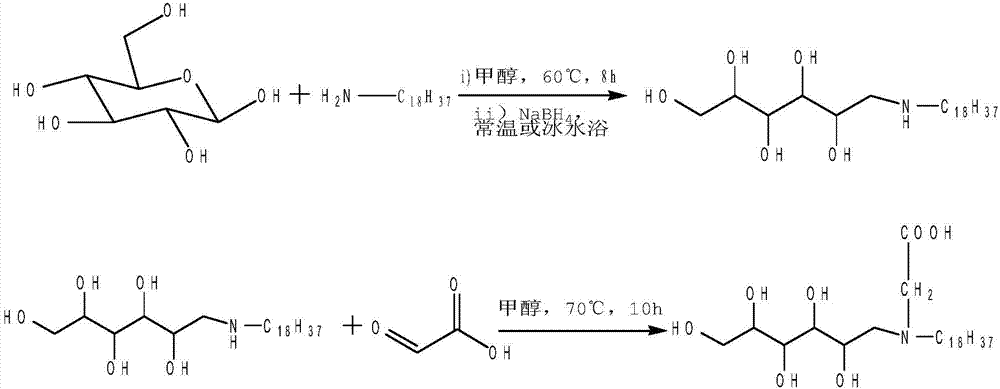

[0022] A kind of preparation method of sugar-based surfactant , including the following steps:

[0023] Step 1: Weigh 6g of glucose, dissolve it in 100mL of methanol at 60°C, then add octadecylamine to glucose molar ratio of 1:1, and stir and react with glucose at 60°C for 8h to prepare Get alkylglucosimine, then add excess NaBH 4 And stir at room temperature or under an ice-water bath until no bubbles are generated, and the crude product of alkyl glucosamine is obtained;

[0024] Step 2: washing the prepared crude alkylglucosamine with iced absolute ethanol and methanol, and suction filtering to obtain alkylglucosamine;

[0025] Step 3: Dissolve the prepared alkylglucosamine in 100mL of methanol at a temperature of 70°C, and then add glyoxylic acid to make it react with the alkyl Glucosamine was stirred and reacted at 70°C for 10 hours to obtain the crude sugar-based surfactant;

[0026] Step 4: Remove the reaction solvent and unreacted glyoxylic acid from the prepared cr...

Embodiment 2

[0029] A kind of preparation method of sugar-based surfactant , including the following steps:

[0030] Step 1: Weigh 6g of glucose, dissolve it in 100mL of methanol at 55°C, and then add hexadecylamine to the molar ratio of hexadecylamine to glucose at a ratio of 1:1 to make it react with glucose at 55°C for 8 hours to prepare Get alkylglucosimine, then add excess NaBH 4 And stir at room temperature or under an ice-water bath until no bubbles are generated, and the crude product of alkyl glucosamine is obtained;

[0031] Step 2: washing the prepared crude alkylglucosamine with iced absolute ethanol and methanol, and suction filtering to obtain alkylglucosamine;

[0032] Step 3: Dissolve the prepared alkylglucosamine in 100mL of methanol at a temperature of 60°C, and then add glyoxylic acid to make it react with the alkyl Glucosamine was stirred and reacted at 60°C for 10 hours to obtain the crude sugar-based surfactant;

[0033] Step 4: Remove the reaction solvent and unr...

Embodiment 3

[0035] A kind of preparation method of sugar-based surfactant , including the following steps:

[0036] Step 1: Weigh 6g of glucose, dissolve it in 100mL of methanol at 50°C, then add dodecylamine and glucose in a ratio of 1:1 molar ratio of dodecylamine to glucose, and stir and react with glucose for 8 hours at 50°C to prepare Get alkylglucosimine, then add excess NaBH 4 And stir at room temperature or under an ice-water bath until no bubbles are generated, and the crude product of alkyl glucosamine is obtained;

[0037] Step 2: washing the prepared crude alkylglucosamine with iced absolute ethanol and methanol, and suction filtering to obtain alkylglucosamine;

[0038] Step 3: Dissolve the prepared alkylglucosamine in 100mL of methanol at a temperature of 60°C, and then add glyoxylic acid to make it react with the alkyl Glucosamine was stirred and reacted at 60°C for 10 hours to obtain the crude sugar-based surfactant;

[0039] Step 4: Remove the reaction solvent and unr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com