Battery pack power supply system for reducing burning probability of battery packs of electric vehicles

A technology for electric vehicles and power supply systems, which is applied in the direction of electric power devices, power devices, vehicle components, etc., and can solve the problems of excessive current burning of battery packs, reducing the probability of burning of battery packs, and failure to automatically replace battery packs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

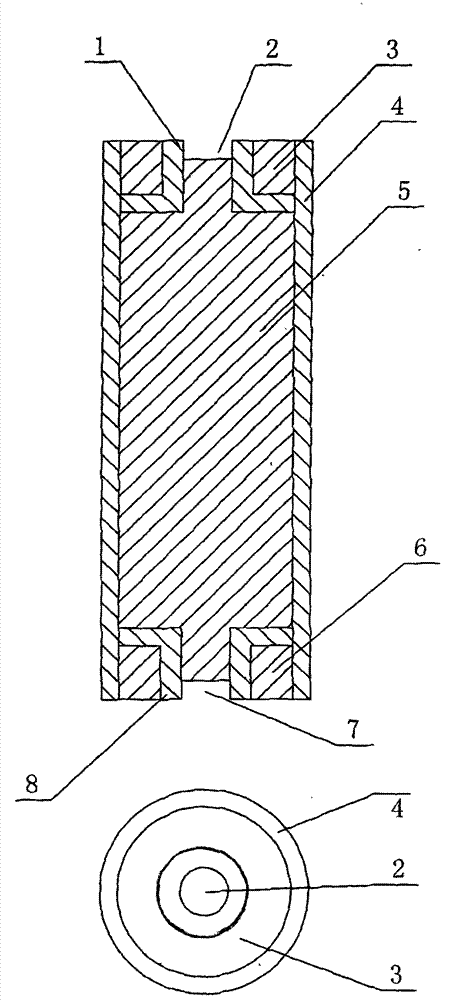

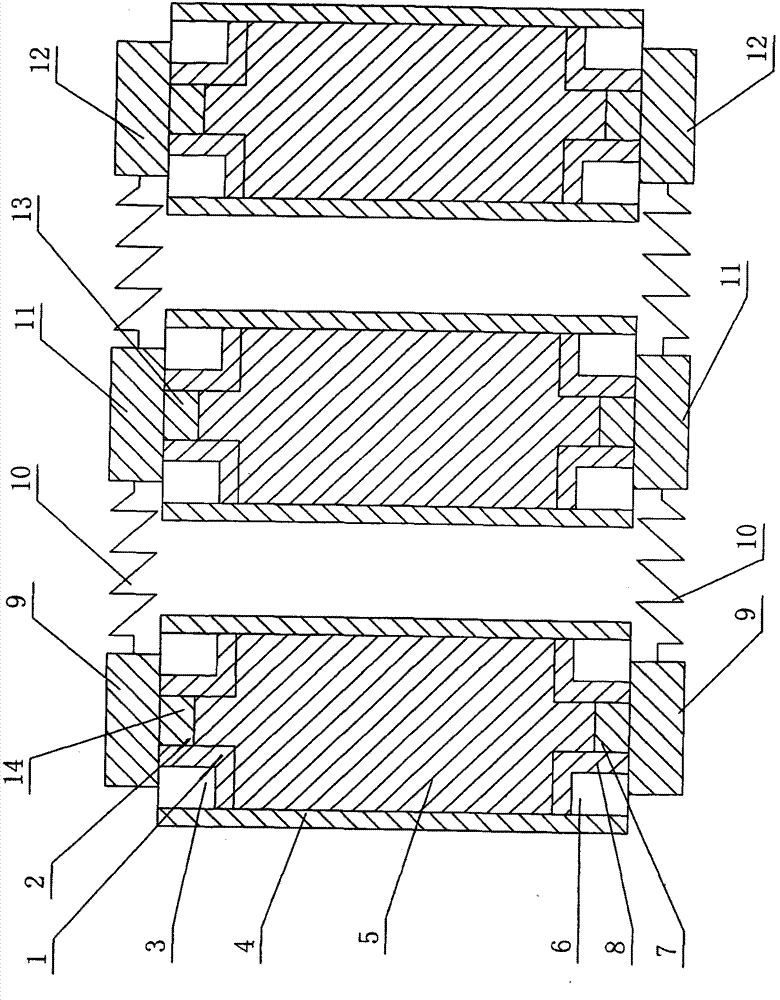

[0061] exist figure 1 In the process, install the first battery sealing cover (3) on both sides of the circular metal casing (4), put the battery (5) into the metal casing (4) and install the second battery sealing cover (6), put the The first battery sealing cover insulating glue (1) is installed in the inside of the first battery sealing cover (3), and the second battery sealing cover insulating glue (8) is installed in the inside of the second battery sealing cover (6). There is a distance from the first wiring port (2) to the top of the first battery sealing cover (3), and a distance from the second wiring port (7) of the battery power supply to the top of the first battery sealing cover (6).

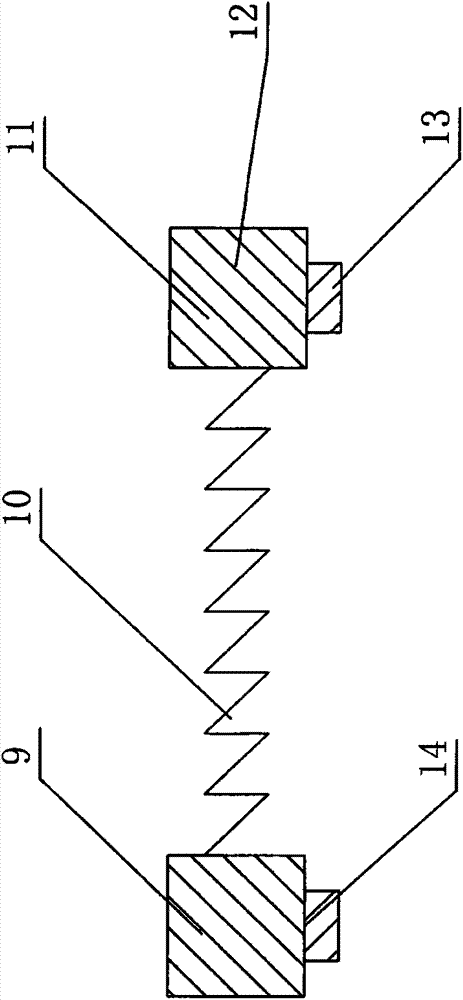

[0062] exist figure 2 Among them, the helical power line (10) in the battery pack electrode connection line (12) is connected to the first contact magnet (9) of the power lead, and the helical power line (10) passes through the inside of the first contact magnet (9) of the power l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com