Cutting machine with fan

A cutting machine and fan technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that the cutting machine does not have the function of relieving heat and cooling, and achieves the effect of convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

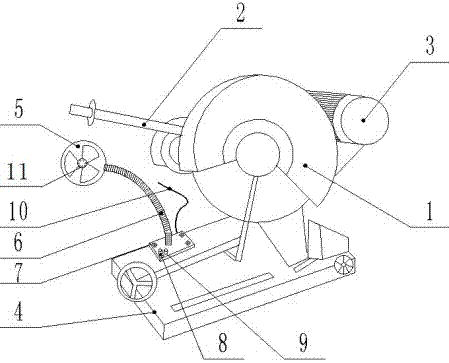

[0011] Embodiment 1: as figure 1 A cutting machine with a fan, including a grinding wheel 1, a motor 2, a handle 3, and a base plate 4, is characterized in that an electric fan 5 is arranged on the cutting machine, and the electric fan 5 is connected with a base 7 by a connecting rod 6. The base 7 is fixed on the bottom plate 4 of the cutting machine with screws, the electric fan 5 is connected with the fan switch 8, the fan switch 8 is connected with the power supply 10, the power supply 10 is an independent power supply, protruding from the rear of the base 7, and connected with the external power supply .

[0012] The cutting machine with electric fan provided in this embodiment can install the electric fan on the cutting machine when the temperature is high in summer, and turn on the electric fan to achieve the purpose of relieving heat and cooling down, while in autumn and winter, the temperature is low. When not in use, it can be removed directly, which is convenient an...

Embodiment 2

[0013] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that: the connecting rod 6 is a universal tube adjustable in one direction, and the staff can arbitrarily adjust the angle and direction of the electric fan during work. Position, to achieve the goal of not affecting the work, but also maximizing the role.

[0014] There is also an LED light group 11 in the center of the electric fan 5, which is connected to the LED light switch 9 in the base 7 through the connecting rod 6, and the LED light switch 9 is directly connected to the power supply 10. At night or when the lighting conditions are not good, the electric fan It can also be used as a lighting lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com