Method for extracting and separating valuable metals from high leaching slag produced by hydrometallurgy

A valuable metal, high leaching slag technology, applied in solid separation, flotation and other directions, can solve the problems of high recovery cost, poor practical operability, and high technical difficulty of associated metals, and achieve the enrichment of valuable metal grade, effective separation, Strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

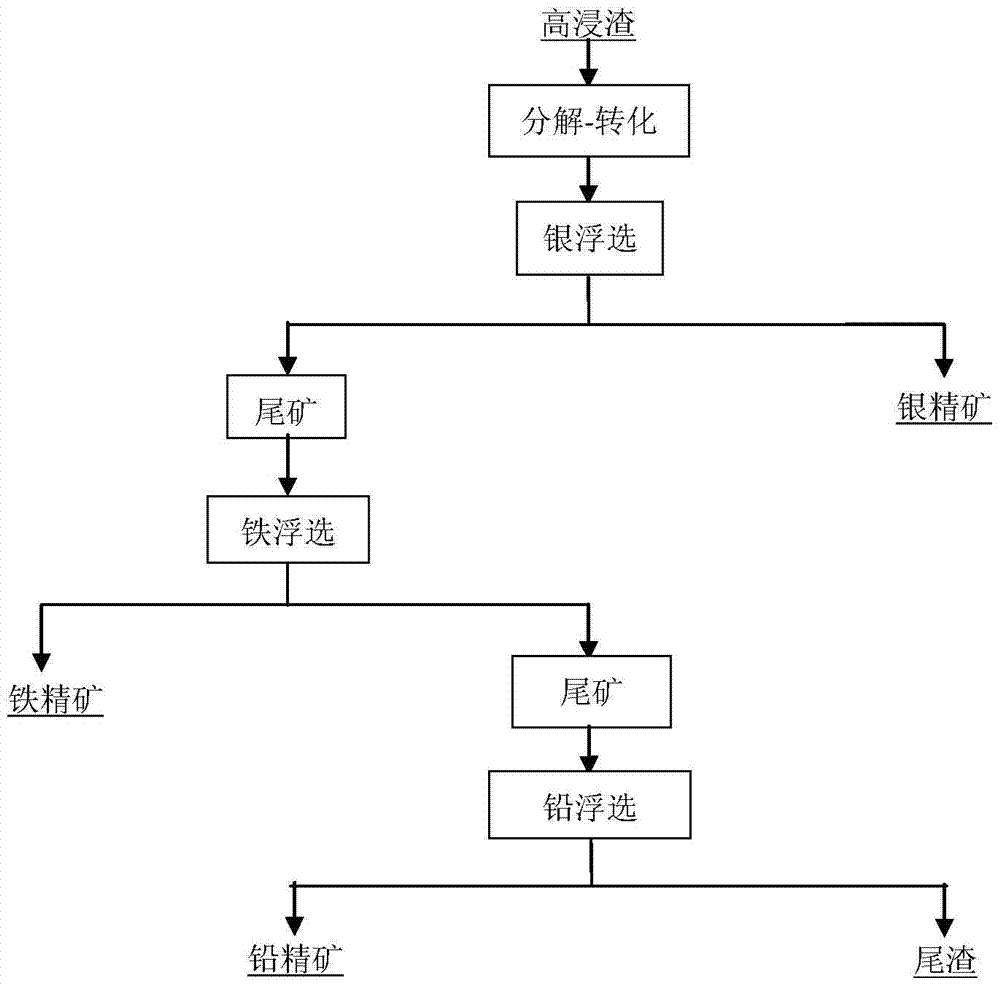

[0026] Example 1: Taking the lead-silver slag composition as silver content 260g / t, iron mass percentage 25%, and lead mass percentage 7% as an example, extraction and separation from the high leaching slag produced by wet zinc smelting The method for valuable metals comprises two steps: (1) decomposition and enrichment of high leaching slag; (2) flotation; wherein,

[0027] (1) Decomposition and enrichment of high leaching slag: Under strong alkaline conditions, the valuable metal elements released after decomposition of jarosite and silicate in high leaching slag are converted into forms that are easy to float;

[0028] (2) Flotation: the silver, iron, and lead in the high leaching slag after step (1) decomposed-transformed are selected through flotation technology to select silver concentrate, iron concentrate and lead concentrate respectively.

[0029]Specifically, step (1) decomposes and enriches high leaching residue, mixes water and high leaching residue at a mass ratio...

Embodiment 2

[0040] Example 2: Taking the lead-silver slag composition as an example with a silver content of 300g / t, an iron mass percentage of 23%, and a lead mass percentage of 6% as an example, extraction and separation from the high leaching slag produced by wet zinc smelting The method for valuable metals comprises two steps: (1) decomposition and enrichment of high leaching slag; (2) flotation; wherein,

[0041] (1) Decomposition and enrichment of high leaching slag: Under strong alkaline conditions, the valuable metal elements released after decomposition of jarosite and silicate in high leaching slag are converted into forms that are easy to float;

[0042] (2) Flotation: the silver, iron, and lead in the high leaching slag after step (1) decomposed-transformed are selected through flotation technology to select silver concentrate, iron concentrate and lead concentrate respectively.

[0043] Specifically, step (1) decomposes and enriches the high leaching residue, mixes water and ...

Embodiment 3

[0054] Example 3: Taking the lead-silver slag composition as silver content 200g / t, iron mass percentage 22%, and lead mass percentage 5% as an example, extraction and separation from the high leaching slag produced by wet zinc smelting The method for valuable metals comprises two steps: (1) decomposition and enrichment of high leaching slag; (2) flotation; wherein,

[0055] (1) Decomposition and enrichment of high leaching slag: Under strong alkaline conditions, the valuable metal elements released after decomposition of jarosite and silicate in high leaching slag are converted into forms that are easy to float;

[0056] (2) Flotation: the silver, iron, and lead in the high leaching slag after step (1) decomposed-transformed are selected through flotation technology to select silver concentrate, iron concentrate and lead concentrate respectively.

[0057] Specifically, step (1) decomposes and enriches the high leaching slag, mixes water and high leaching slag at a mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com