Shield station passing method of first passing large shield through station and then building air flue structure

A technology of shield tunneling and air duct, which is applied in tunnels, earthwork drilling, tunnel lining, etc., and can solve problems that affect the efficiency of shield tunneling, long construction periods, and complicated construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

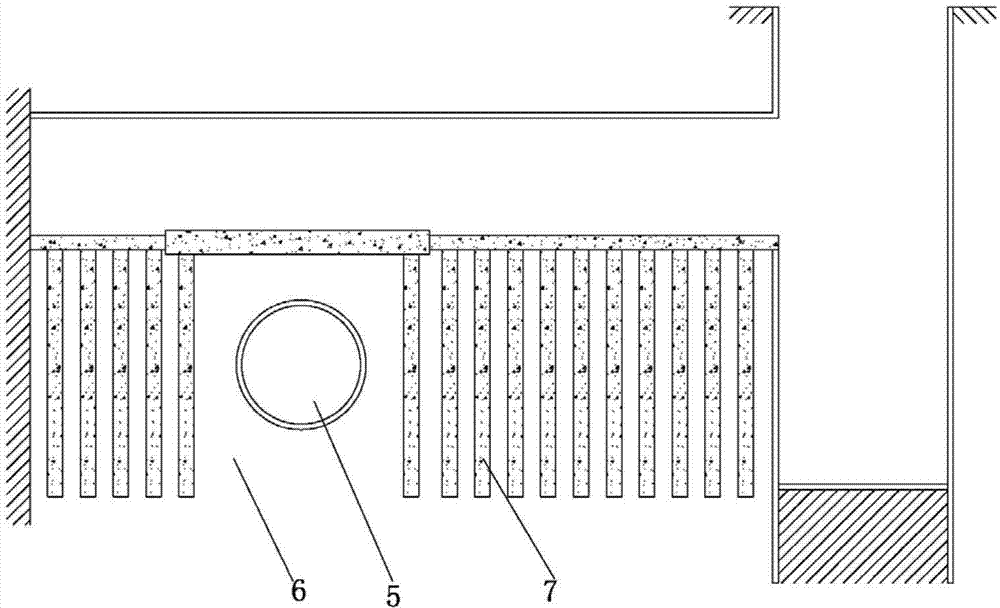

[0017] Please refer to the attached figure 1 To attach image 3 As shown, the present invention is a shield tunnel passing method in which a large shield passes the station first and then builds an air duct structure, which includes the following steps:

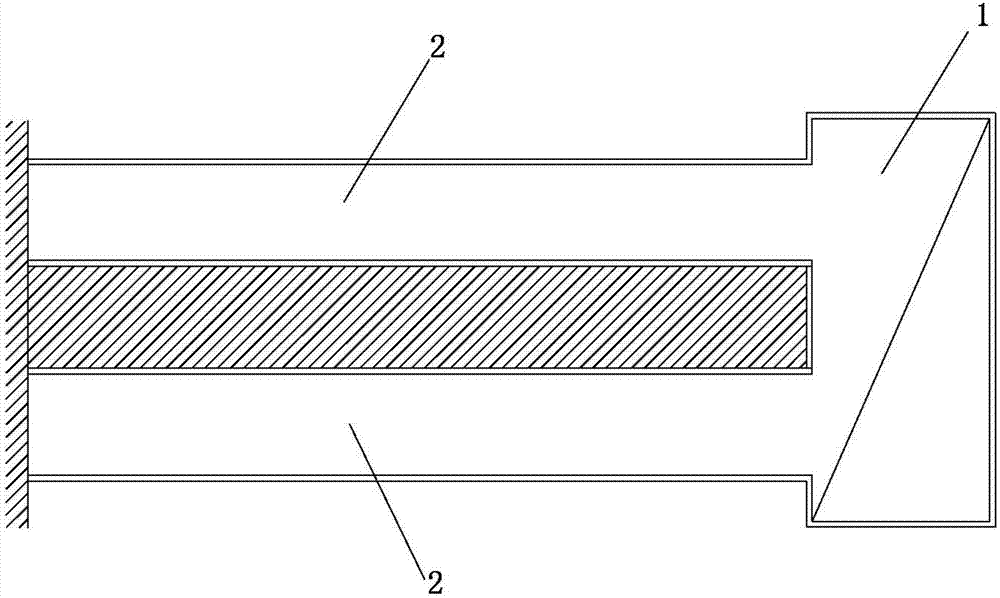

[0018] 1), such as figure 1 As shown, the vertical shaft 1 is used as the construction channel, and the horse head gate is opened on the side wall of the shaft, and the soil at the horse head gate is reinforced by grouting, and the three grids at the horse head gate are closely arranged. The small pilot tunnel 2 is excavated by the short step method, and the core soil is left. The step distance of each excavation is not greater than 0.75m. The soil in the arch part is reinforced by grouting with advanced small conduits, and the grouting grout is cement slurry. If the stratum contains water, it should be filled with cement-water glass double-fluid slurry;

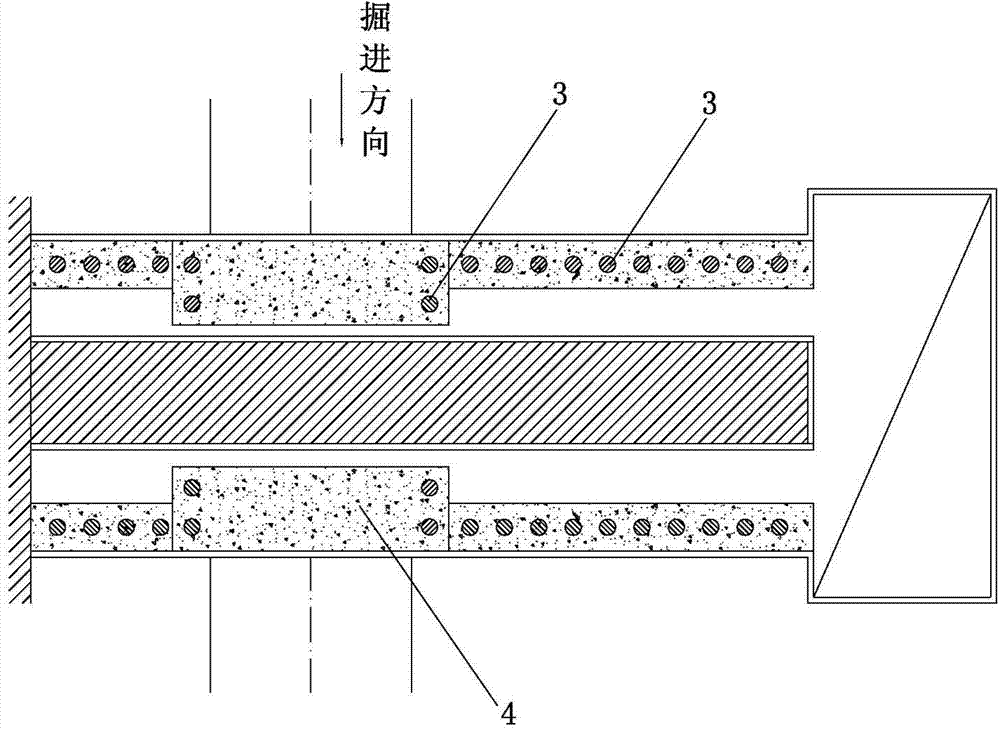

[0019] 2), such as figure 2 As shown, the bored cast-in-place pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com