Method for preparing super-high-bulk paper pulp from fir slabs

A technology of ultra-high looseness and slabs, applied in the field of papermaking, can solve the problems of unsatisfactory use effect and unsuitable for papermaking bulkiness, etc., and achieve the effects of increasing surface area, good chemical treatment effect, and excellent bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

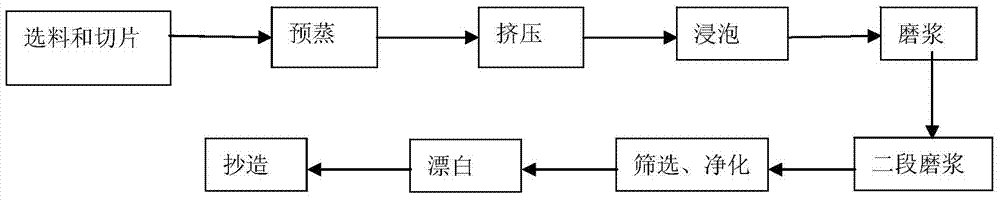

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of method for preparing ultra-high bulk paper pulp with Chinese fir board, comprises the following steps:

[0026] (1) material selection and slicing: select the 1-2cm thick Chinese fir slab after removing the coring in the wood processing factory, remove the rough skin of the slab outer layer and slice it with a drum slicer. The slicing specification is 2-2.5cm long. The width is 4.5cm. After being sliced, it is sent to the wood chip swing screen through the conveyor belt, and the wood chips and wood knots are screened out, and then sent to the wood chip warehouse for storage;

[0027] (2) Pre-steaming: The wood chips prepared in step (1) are first washed to remove dust through the washing device, and then remove heavy impurities such as wood knots and stones, and then send them into the preheating bin, inject steam, and control the preheating bin The temperature is 90°C, the pre-steaming time is 10 minutes, and the wood chips are initially softene...

Embodiment 2

[0036] Embodiment 2, a kind of method for preparing ultra-high bulk paper pulp with Chinese fir board, comprises the following steps:

[0037] (1) material selection and slicing: select the 1-2cm thick Chinese fir slab after removing the coring in the wood processing factory, remove the rough skin of the slab outer layer and slice it with a drum slicer. The slicing specification is 2-2.5cm long. The width is 4.5cm. After being sliced, it is sent to the wood chip swing screen through the conveyor belt, and the wood chips and wood knots are screened out, and then sent to the wood chip warehouse for storage;

[0038] (2) Pre-steaming: The wood chips prepared in step (1) are first washed to remove dust through the washing device, and then remove heavy impurities such as wood knots and stones, and then send them into the preheating bin, inject steam, and control the preheating bin The temperature is 93°C, the pre-steaming time is 15 minutes, and the wood chips are initially softene...

Embodiment 3

[0047] Embodiment 3, a kind of method for preparing ultra-high bulk paper pulp with Chinese fir board, comprises the following steps:

[0048] (1) material selection and slicing: select the 1-2cm thick Chinese fir slab after removing the coring in the wood processing factory, remove the rough skin of the slab outer layer and slice it with a drum slicer. The slicing specification is 2-2.5cm long. The width is 4.5cm. After being sliced, it is sent to the wood chip swing screen through the conveyor belt, and the wood chips and wood knots are screened out, and then sent to the wood chip warehouse for storage;

[0049] (2) Pre-steaming: The wood chips prepared in step (1) are first washed to remove dust through the washing device, and then remove heavy impurities such as wood knots and stones, and then send them into the preheating bin, inject steam, and control the preheating bin The temperature is 95°C, the pre-steaming time is 20 minutes, and the wood chips are initially softene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com