Method for preparing few-layer graphene by using auxiliary reagent

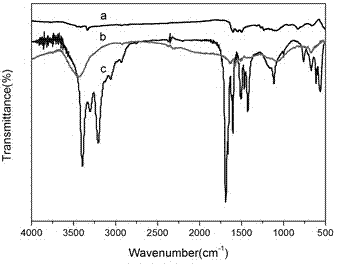

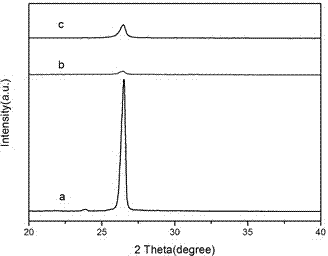

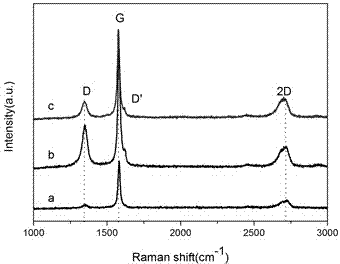

A few-layer graphene and reagent technology, applied in the field of nanomaterials, can solve the problems of cumbersome process, high cost, and poor quality, and achieve the effect of simple operation, less structural defects, and complete planar structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) When the ambient temperature is not higher than 50°C, mix 1g of natural graphite powder with 5g of ammonium citrate, put it into a ball mill jar with a diameter of 8cm and a volume of 100mL, mill at 400rpm for 12h, cool to room temperature, and take out the mixture;

[0021] (2) Disperse the mixture in 800mL distilled water, stir it mechanically at a rate of 500rpm for 30min, then let the dispersion stand still, after layering, collect the upper layer dispersion liquid for suction filtration, wash the filtrate with distilled water to remove ammonium citrate, until the washing liquid is neutral;

[0022] (3) Add distilled water to the filtrate to re-disperse, centrifuge the dispersion at 2000 rpm for 10 min, take the upper suspension, and repeat the centrifugation twice.

[0023] (4) Suction-filter the upper layer suspension obtained by the second centrifugation again, dry the suction-filtered product together with the filter membrane at 60°C, and finally scrape t...

Embodiment 2

[0025] (1) Mix 1g of natural graphite powder with 5g of azodicarbonamide, put it into a ball mill jar with a diameter of 8cm and a volume of 100mL, mill at 400rpm for 24h, cool to room temperature, and take out the mixture;

[0026] (2) Prepare distilled water and ethanol at a volume ratio of 1:1 to make a dispersing solvent, disperse the mixture in 800 mL of dispersing solvent, ultrasonicate at a frequency of 40HZ for 30min, and then stand for stratification, collect the upper dispersion liquid, and analyze the dispersion The liquid is subjected to suction filtration, the filtrate is washed with a dispersing solvent, and azodicarbonamide is removed until the color of the washing liquid is colorless;

[0027] (3) Add a dispersing solvent to the filtrate to re-disperse, centrifuge the dispersion at 2000rpm for 10min, take the upper suspension, and repeat the centrifugation twice.

[0028] (4) Suction-filter the upper layer suspension obtained by the second centrifugation again,...

Embodiment 3

[0034] (1) Mix 1g of natural graphite powder with 20g of sodium hydroxide, put it into a ball mill jar with a diameter of 10cm and a volume of 250mL, mill at 300rpm for 8h, cool to room temperature, and take out the mixture.

[0035] (2) Disperse the mixture in 1000mL of distilled water, stir mechanically for 30min, let stand to separate layers, and collect the upper dispersion.

[0036] (3) Centrifuge the dispersion at 1000rpm for 10min, take the upper suspension, then centrifuge at 2000rpm for 10min, take the upper suspension.

[0037] (4) Transfer the obtained dispersion to a dialysis bag for dialysis to remove Na + and other impurity ions.

[0038] (5) Suction-filter the dispersion, dry the suction-filtered product together with the filter membrane at 60°C, and finally scrape off the product from the filter membrane to obtain a few-layer graphene powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com