A three-dimensional printing method and device for integrated manufacturing of tissue/organ chips

A technology of three-dimensional printing and organ chips, which is applied in the manufacture of auxiliary devices, coating devices, processing and manufacturing, etc., can solve the problems of long processing cycle, high mask manufacturing cost, and reduced system flexibility, so as to reduce cell damage, The process is simple and the effect of reducing the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

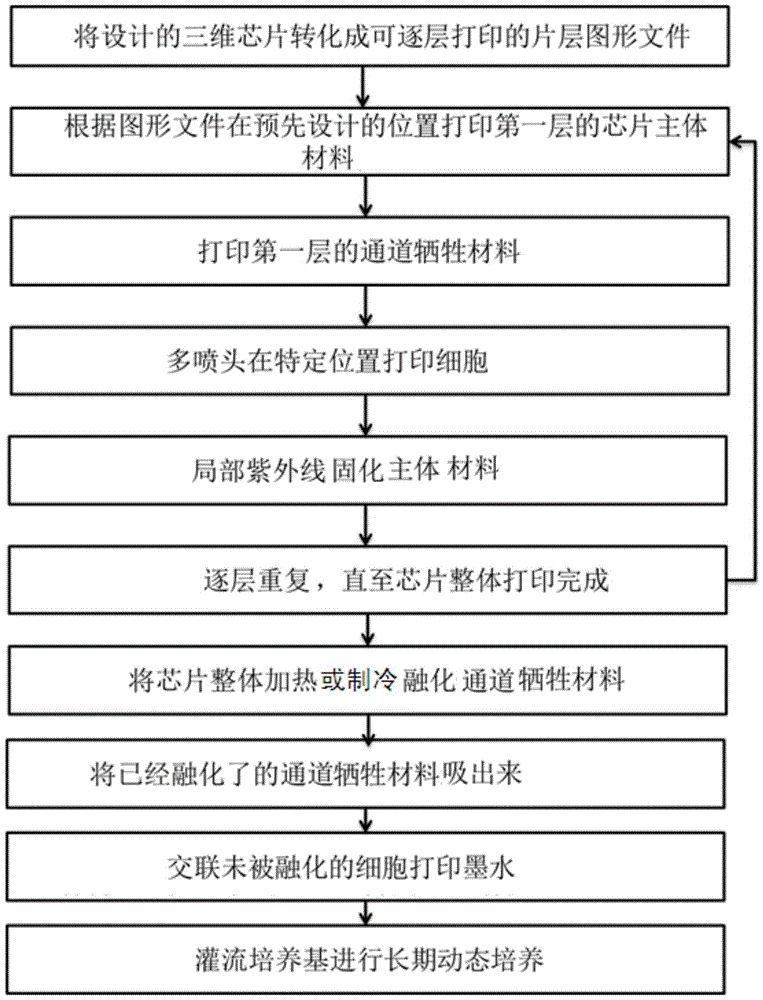

[0029] Such as figure 1 As shown, the three-dimensional printing method for tissue / organ chip integrated manufacturing of the present invention includes the following steps:

[0030] 1) Using existing 3D drawing software (such as Solidworks, but not limited to this) to design a 3D structure diagram of a 3D chip, and saving the designed 3D structure diagram in STL format, but not limited to this; The layer method converts the 3D structure diagram of the 3D chip into a slice graphic file that can be recognized by a 3D printing device, and the slice graphic file can adopt the cli format, but is not limited thereto;

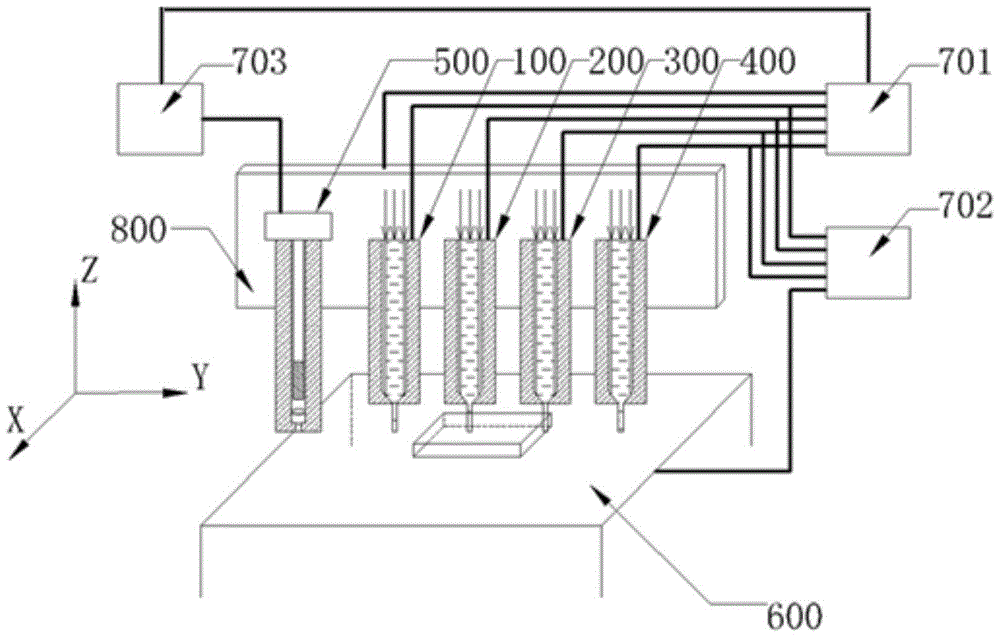

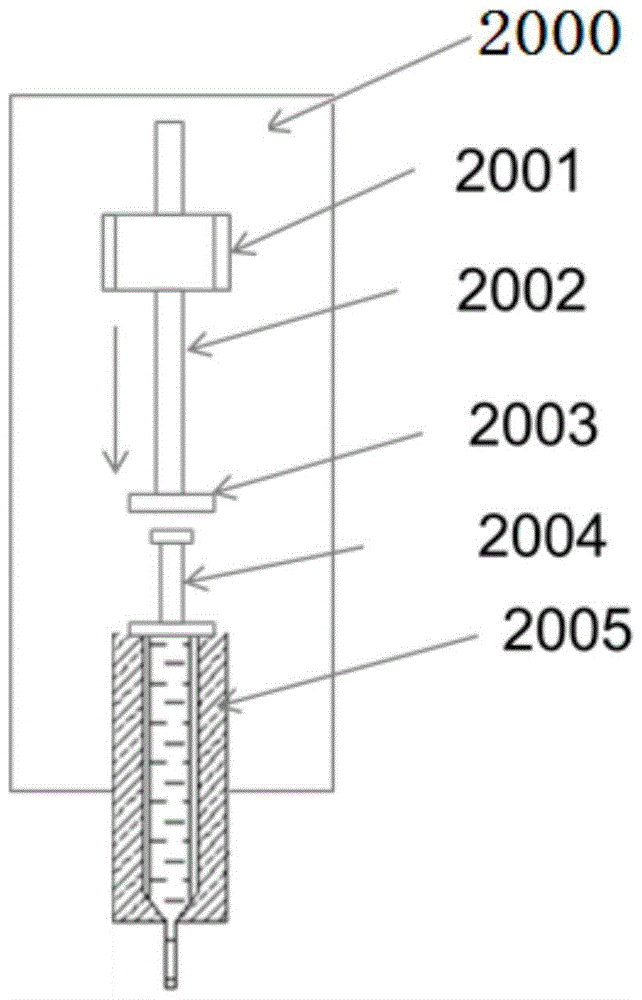

[0031] 2) First, turn on the 3D printing device, and suck the main material printing ink, sacrificial material printing ink and various cell printing inks into the main material printing nozzle, sacrificial material printing nozzle and mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com