Permanent-magnet brushless motor control system

A permanent magnet brushless motor and control system technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve problems such as changes and influence on the speed regulation accuracy and performance of traditional DC motors, and achieve low noise, The effect of high reliability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

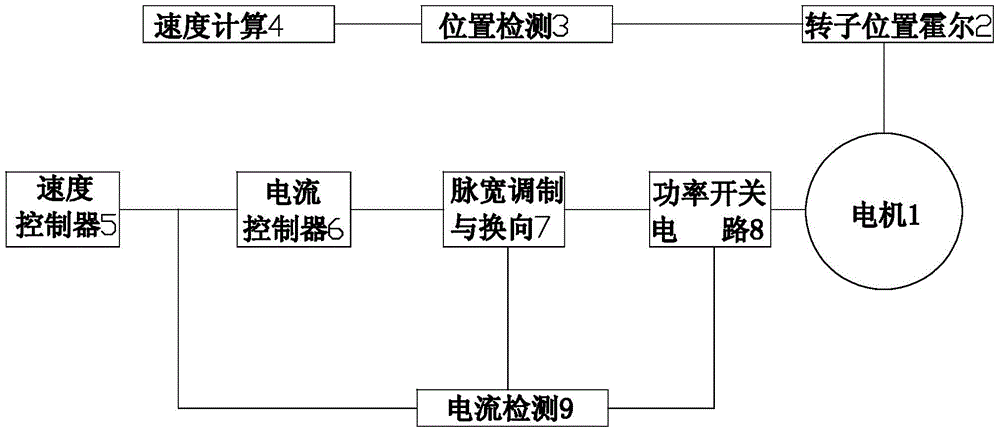

[0010] figure 1 It is a structural schematic diagram of the permanent magnet brushless motor control system of the present invention. The permanent magnet brushless motor control system of the present invention is characterized in that it includes motor 1, rotor position Hall 2, position detection 3, speed calculation 4, speed Controller 5, current controller 6, pulse width modulation and commutation 7, power switch circuit 8, current detection 9;

[0011] The single-chip microcomputer 1 is connected to the alarm module 2, the single-chip microcomputer 1 is connected to the pressure detection module 3, the motor 1 is connected to the rotor position Hall 2, and the rotor position Hall 2 is connected to the position The detection 3 is connected, the position detection 3 is connected with the speed calculation 4, the speed calculation 4 is connected with the speed controller 5, the speed controller 5 is connected with the current controller 6, and the current controller 6 is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap