Current stabilizer tube and manufacturing method thereof

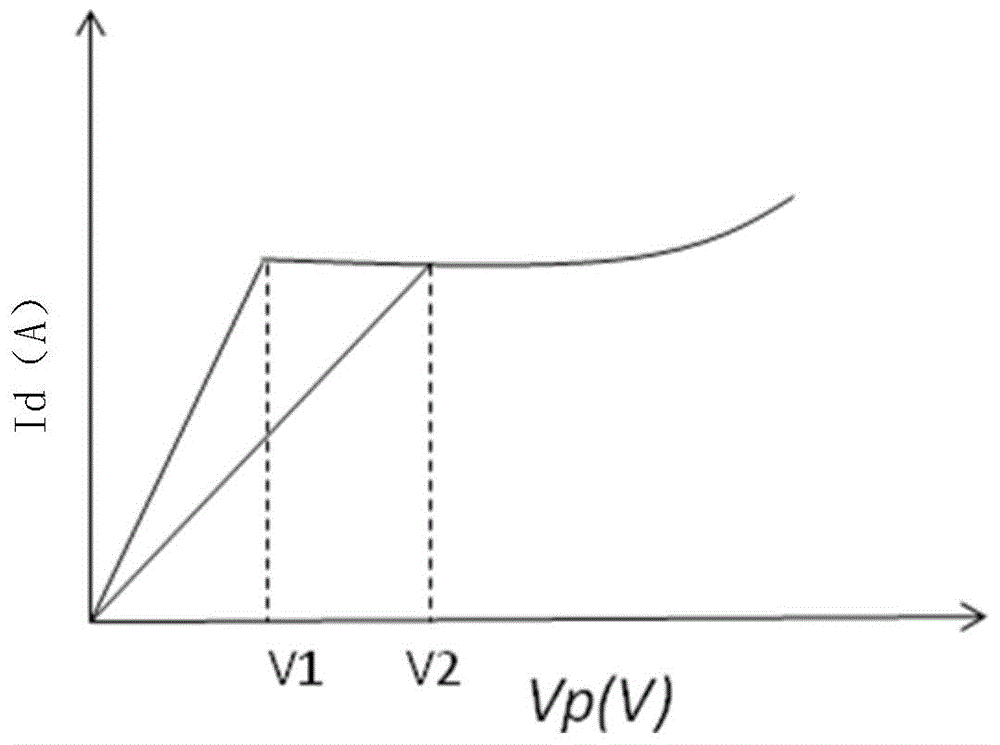

A steady current tube, N-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased pinch-off voltage, decreased reliability, and circuit burnout, to increase the conduction current and improve Reliability, effect of reducing pinch-off voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

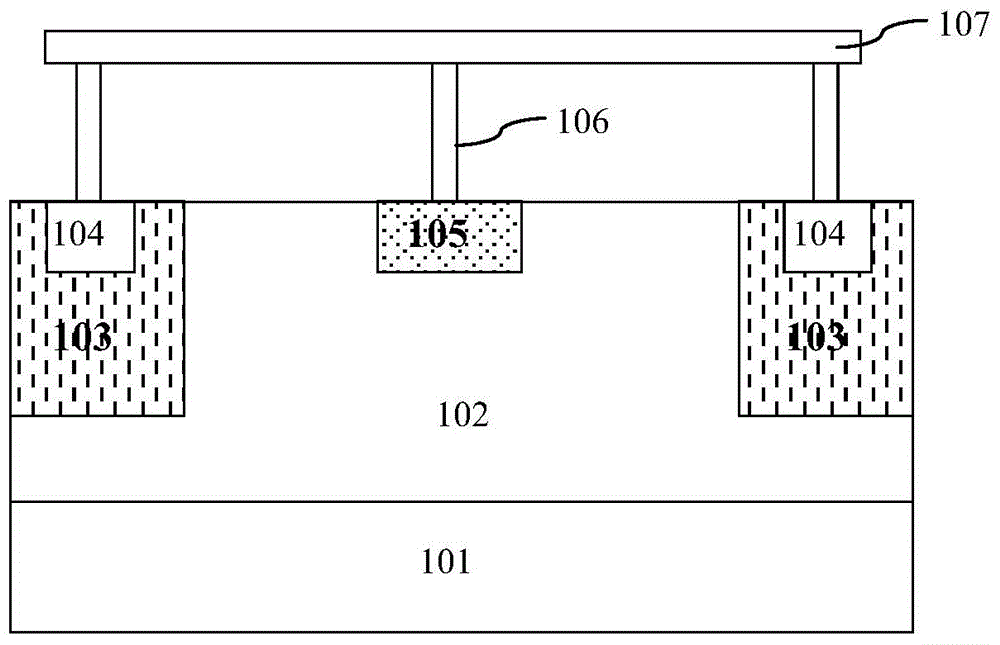

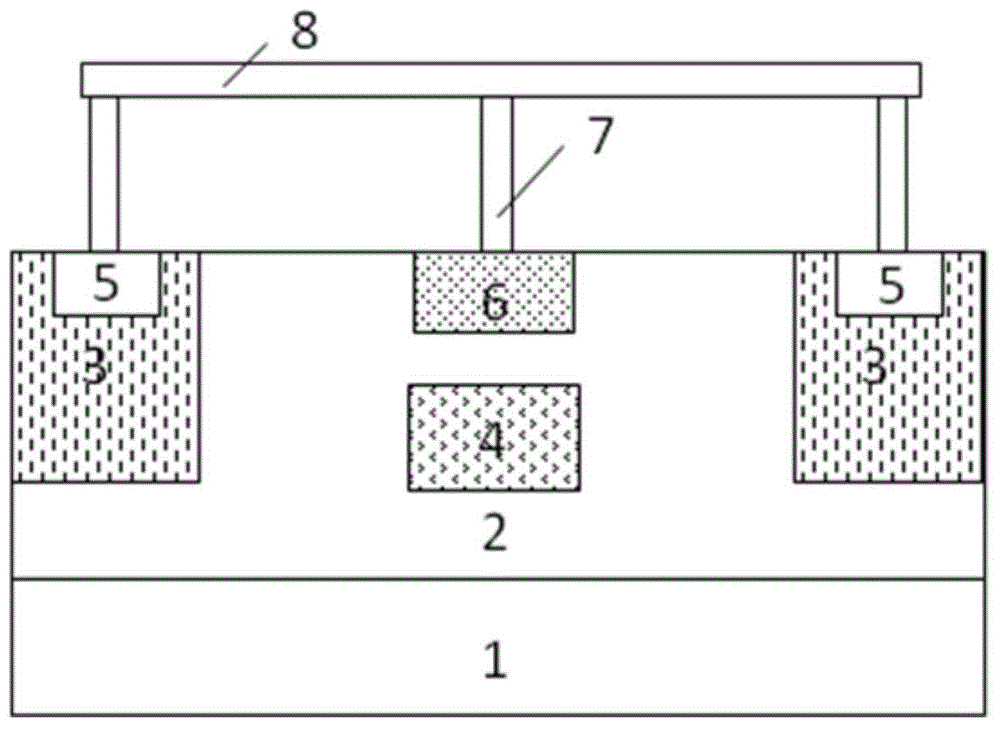

[0033] Such as figure 2 Shown is the structural diagram of the steady flow tube of the embodiment of the present invention; the steady flow tube of the embodiment of the present invention includes:

[0034] P-type heavily doped silicon substrate 1 .

[0035] The P-type epitaxial layer 2 is formed on the front surface of the silicon substrate 1 , the greater the thickness of the P-type epitaxial layer 2 , the greater the longitudinal withstand voltage of the ballast tube.

[0036] Two first N-type regions 3 formed on the surface of the P-type epitaxial layer 2, the two first N-type regions 3 are separated by a certain distance, and the two first N-type regions 3 are located between the two first N-type regions 3 The P-type epitaxial layer 2 forms the longitudinal conductive channel of the steady current tube. The larger the distance between the two first N-type regions 3, the wider the longitudinal conductive channel of the steady current tube. The larger the conduction curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com