Multichannel Hall rotation speed sensor

A Hall speed sensor technology, applied in instrumentation, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems that cannot meet the speed measurement requirements of high-speed motors of EMUs, the number of channels is small, and there is no signal output, etc., to achieve Strong vibration resistance, large induction air gap and wide speed measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

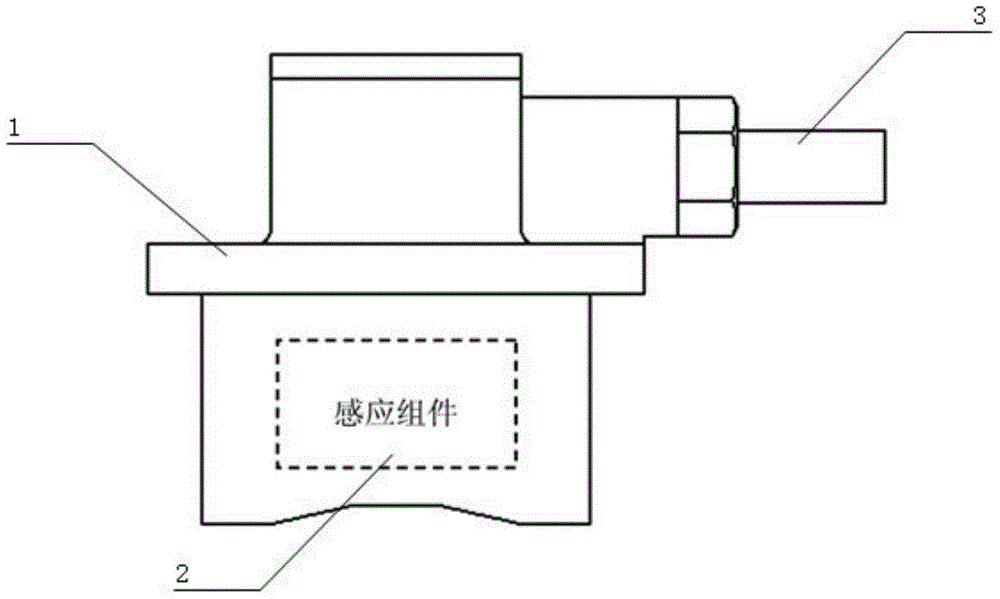

[0066] as attached figure 1 As shown, the sensor at least includes a housing 1 and an induction assembly 2, and the housing 1 is used to install the sensor on the rolling stock wheel set (rolling stock wheel set axle box end cover) or the motor non-drive end cover or the motor drive end cover, And protect its internal devices. The induction component 2 is installed in the casing 1, and is used to sense the rotation speed of the locomotive wheel shaft or motor shaft, and generate 3 to 8 electrical pulse signals whose frequency is proportional to the rotation speed and at least 2 electrical pulse signals with a specific phase difference. The induction assembly 2 is arranged on the top of the speed measuring gear 5, and the speed measuring gear 5 is arranged on the locomotive vehicle wheel shaft or the motor shaft 7, and rotates with the rotation of the locomotive vehicle wheel shaft or the motor shaft 7.

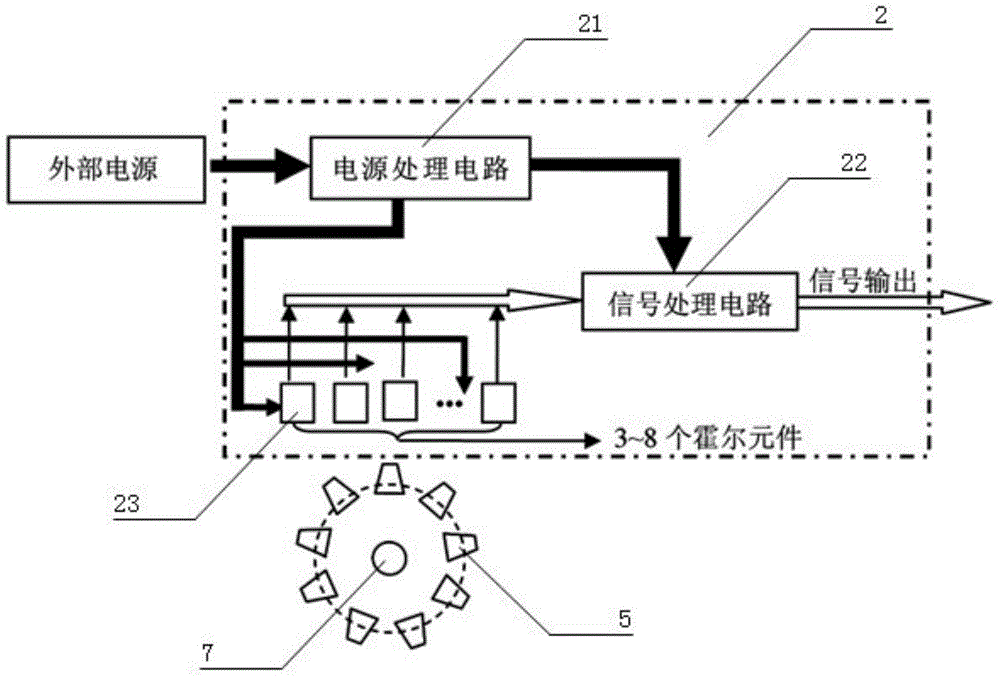

[0067] The sensing component 2 further includes a power processing circu...

Embodiment 2

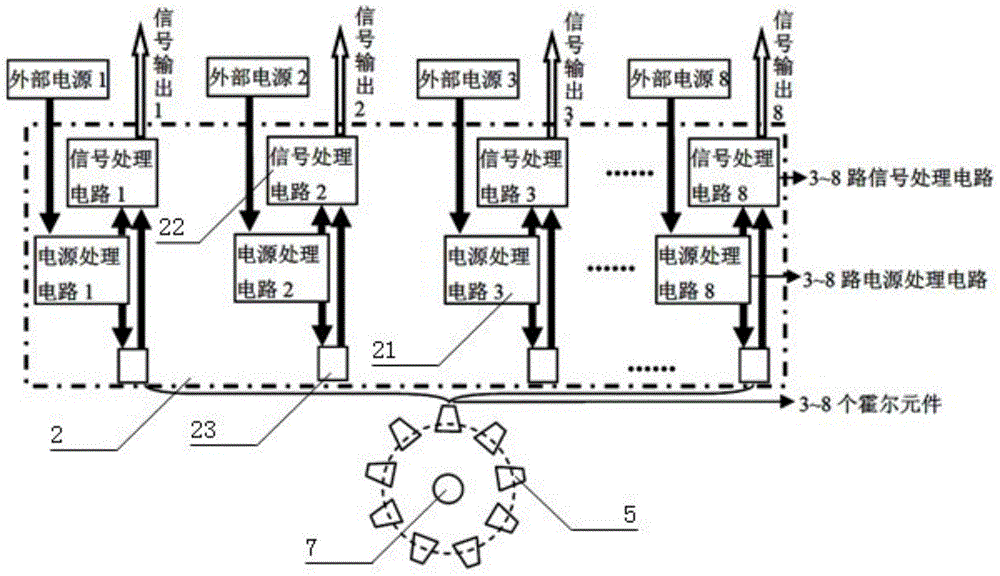

[0069] as attached image 3 As shown, in Embodiment 1, a power processing circuit 21 processes the external power supply to provide power for the multi-channel Hall elements 23 respectively, and a signal processing circuit 22 processes the output signals of the multi-channel Hall elements 23 The technical solutions are different. In this embodiment, the multi-channel Hall speed sensor has multiple power supply processing, signal acquisition and signal processing channels, and the power processing circuit 21, signal processing circuit 22, and Hall element 23 in each channel are electrically independent, that is, It is said that each channel includes an independent power processing circuit 21 and a signal processing circuit 22 . Alternatively, two channels with a specific phase difference share a power supply.

[0070] In the above-mentioned embodiment 1 and embodiment 2, the installation position of at least two Hall elements 23 in the sensor that output the specific phase di...

Embodiment 3

[0076] as attached Figure 4 As shown, in this embodiment, the sensing surfaces of 3 to 8 Hall elements 23 are close to the speed measuring gear 5, and there is an arc surface equidistant from the axis center of the speed measuring gear 5, and the arc surface is connected to each Hall element The sensing surfaces of the elements 23 are all tangent, and the sensing surfaces of 3-8 Hall elements 23 are distributed on multiple planes tangent to the arc surface. At this time, the installation positions of the sensing surfaces of 3 to 8 Hall elements 23, the parameters of the speed measuring gear 5 and the installation air gap of the sensor further conform to the following functional relationship:

[0077] D = ( z + 2 ) m 2 + σ

[0078] θ = 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com