Cooling lubricating system of step-up gear box of wind generating set and low-temperature starting method thereof

A cooling and lubricating, wind turbine technology, applied in wind turbine combination, wind turbine, gear lubrication/cooling, etc., to achieve the effect of smooth start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Lube oil cooler

[0035] Such as figure 1 Shown: the lubricating oil cooler of the present invention includes a radiating plate 7.2 and a one-way valve 7.1 arranged on the lubricating oil delivery pipeline. The radiating plate 7.2 and the one-way valve 7.1 are arranged in parallel, and the one-way valve 7.1 or the lubricating oil delivery pipeline 6 communicating with the one-way valve 7.1 is integrated on the heat sink 7.2. Preferably, the one-way valve 7.1 or the lubricating oil delivery pipeline 6 communicating with the one-way valve 7.1 is integrated inside the heat dissipation plate 7.2, so as to maximize the one-way valve 7.1 or be connected to the one-way valve 7.1 The efficiency of heat transfer from the connected lubricating oil delivery pipeline to the heat sink 7.2. Preferably, it also includes a cooling fan 7.3 for cooling and ventilating the heat sink 7.2, so as to improve the heat dissipation efficiency of the heat sink 7.2. Of course, the cooler...

Embodiment 2

[0036] Example 2 Speed-increasing gearbox cooling and lubricating system and wind turbine unit adopting the speed-increasing gearbox cooling and lubricating system and low-temperature starting method of wind turbine unit

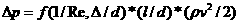

[0037] The speed-increasing gearbox cooling and lubricating system of the present invention, such as figure 1 with 2 As shown, it includes a two-speed oil pump 1, an overflow valve 2, a filter 3, a differential pressure sensor 4, a temperature control valve 5, a lubricating oil delivery pipeline 6, a lubricating oil cooler 7, a lubricating oil distributor 10, a heater 11 and The speed increasing gear box 12, wherein the cooler 7 preferably includes a one-way valve 7.1, a heat dissipation plate 7.2, and a cooling fan 7.3, wherein the one-way valve 7.1 is integrated in the heat dissipation plate 7.2 in a parallel manner, such as figure 1 Shown. Preferably, the speed-increasing gearbox cooling and lubricating system provided in this embodiment may further include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com