Aluminum electrolysis carbon pre-baking anode pre-heating method

A technology of prebaked anodes and carbon anodes, which is applied in the field of aluminum electrolysis production, can solve the problems that the heat energy of the flue gas is not effectively utilized, affects the normal operation of the electrolytic cell, and reduces the current efficiency of the cell. It has broad prospects for industrial application and is beneficial to Normal operation, effect of improving cell current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

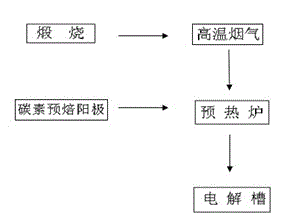

[0063] Such as figure 1 As shown, the main process of the present invention includes: transporting the assembled carbon prebaked anode to the preheating furnace, and then charging the furnace, and heating the anode through heat exchange by using the high-temperature flue gas from the aluminum carbon calcining rotary kiln , and then take out the anode, put it into the heat preservation device, transport it to the aluminum electrolytic cell, and replace the old anode in time on the ground for use.

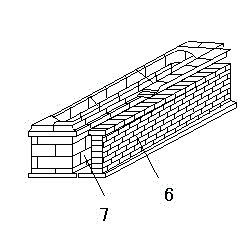

[0064] Such as figure 2 As shown, it is a preheating furnace structure. The temperature of the high-temperature flue gas from the calcination process is 700-1100°C, and the flow rate is very high. The high-temperature flue gas passes through the fire channel 2, and then transfers heat to the carbon through the partition wall 1. Pre-bake the anode and complete the heating process.

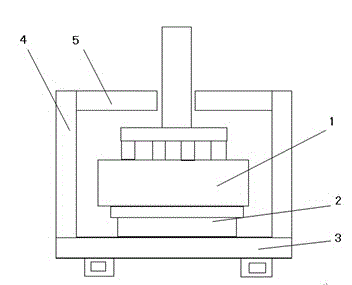

[0065] Such as image 3 As shown, the heat preservation chamber for preheating anodes is a box-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com