Rose stock solution for preparing rose wine and preparation method thereof

A technology of rose and raw liquid, which is applied in the field of food processing, can solve the problems of insufficient natural aroma of roses, rich and unnatural, etc., and achieve good market prospects, low equipment requirements, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

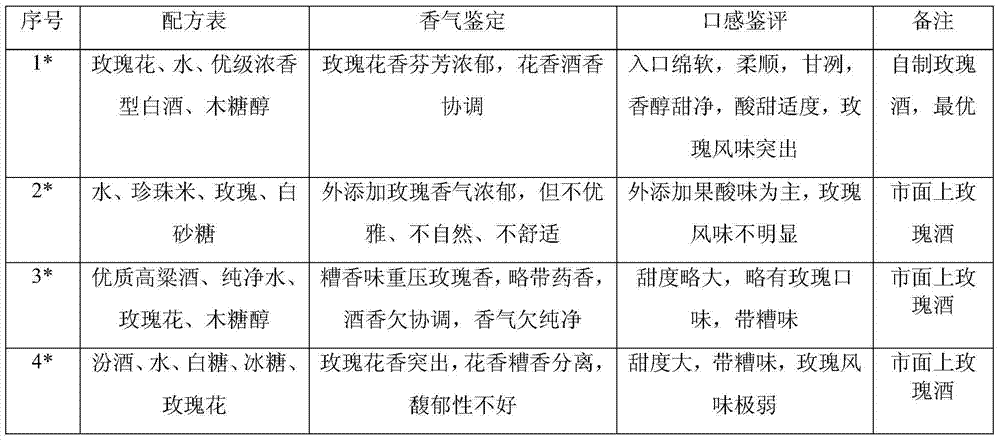

Embodiment 1

[0051] Raw material processing: remove the calyx from the dried roses and fresh roses, and crush the dried roses after removing the calyxes with a HX-200 traditional Chinese medicine grinder. The crushed particle size of the dried roses is 20 mesh to 40 mesh;

[0052] Extraction: put the calyx-removed rose flowers into the extraction tank according to the weight ratio of rose flowers and white wine at 1:2, add 5000mL of 50% vol base wine; crush the dried rose flowers with the calyx removed according to the weight of dried rose flowers and white wine The ratio is 1:5, put it into the extraction tank, add 5000mL of 50% vol base wine; the soaking time is 30 days, and the extraction temperature is 30°C; stir for 0.5 hours every day, so that the material and liquid are mixed evenly;

[0053] Vacuum distillation treatment: After the rose extract is filtered through gauze and rose slag, it is subjected to vacuum distillation at a temperature of 65°C and a pressure of 0.06-0.08 MPa to ...

Embodiment 2

[0059] Extract the roses obtained through raw material treatment in Example 1. The extraction process is the same as in Example 1. The ratio of solid to liquid is configured as 1:15 by weight ratio of dried rose flowers to white wine, and 1:8 by weight ratio between fresh rose flowers and white wine. The time of soaking and extraction is 20 days, the concentration of the base wine is 60% vol, and the extraction temperature is 20°C; the rose dried flower extract and the rose flower extract are decompressed at a temperature of 65°C and a pressure of 0.06-0.08MPa After distillation, 60% vol rose dried flower mother liquor and 50% vol rose flower mother liquor are obtained.

Embodiment 3

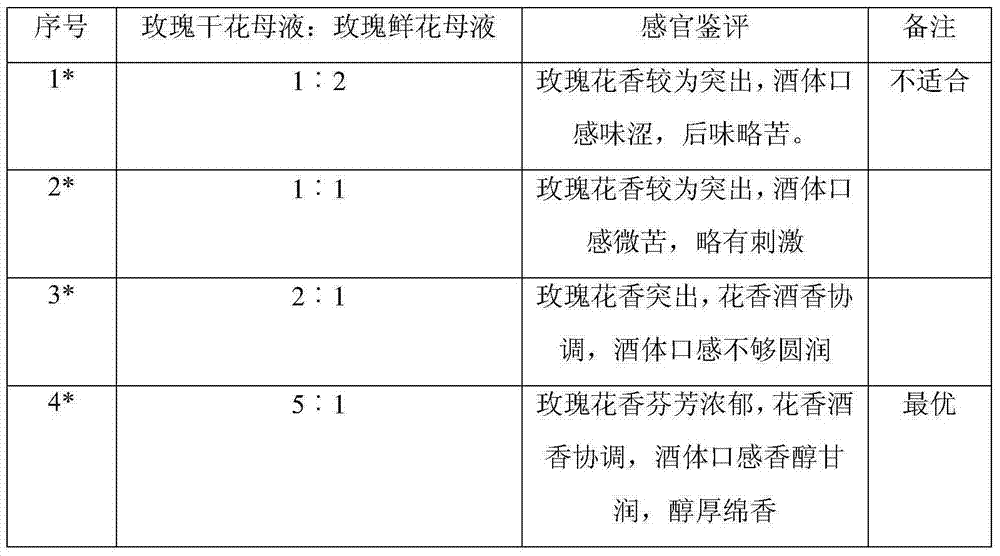

[0061] Extract the roses obtained through raw material treatment in Example 1. The extraction process is the same as that in Example 1. The ratio of solid to liquid is configured such that the weight ratio of rose dried flowers to white wine is 1:10, and the weight ratio of rose flowers to white wine is 1:5. The time of soaking and extraction is 30 days, the concentration of base wine is 55% vol, and the extraction temperature is 25°C; the dried rose flower extract and the rose flower extract are decompressed at a temperature of 60°C and a pressure of 0.06-0.08MPa After distillation, 57% vol rose dried flower mother liquor and 45% vol rose flower mother liquor were obtained; the rose flower mother liquor and rose dried flower mother liquor were mixed according to the weight ratio of 1:3 to obtain rose comprehensive mother liquor with alcohol content of 54% vol. The concentration of the rose comprehensive mother liquor was reduced to obtain a rose liquid with an alcohol content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com