Application of biodiesel in preparation of biodegradable rust preventing oil

A biodiesel and biodegradation technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of metal rust prevention, thin oil film strength, waste of resources, etc. The effect of using and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

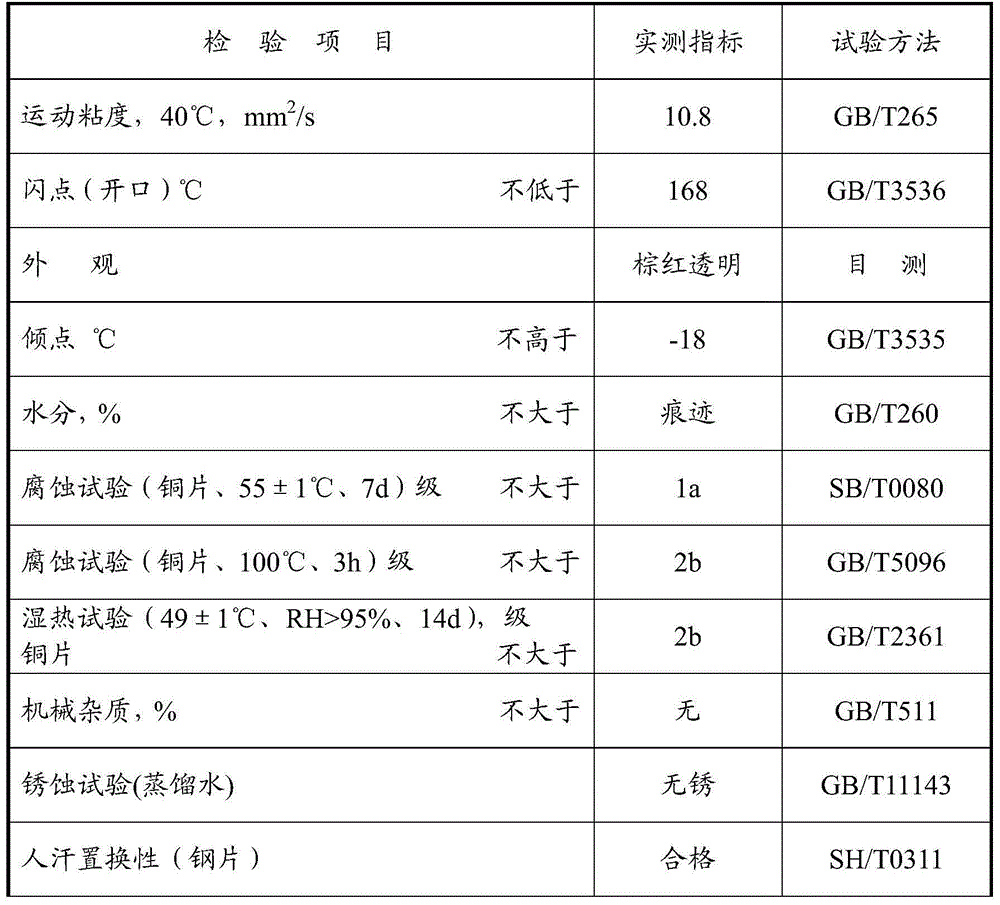

Examples

Embodiment 1

[0021] Embodiment 1 biodiesel is used for producing L-F 20-1 Sealed anti-rust oil

[0022] Pump 25 parts by weight of paraffin-based 32# base oil and 44.5 parts by weight of biodiesel into the vacuum reactor, stir, self-circulate and heat up to 75 ° C; sequentially pump the following additives in parts by weight: ① methyl silicone oil: 0.01 Part ② Benzotriazole: 0.01 part ③ 2,6 di-tert-butyl-p-cresol: 0.48 part ④ Zinc naphthenate: 5 parts ⑤ Alkenyl succinate: 2 parts ⑥ Sorbitan monooleate (Emulsifier S-80): 2 parts ⑦ Oxidized petroleum grease barium soap: 4 parts ⑧ Barium dinonylnaphthalene sulfonate: 5 parts ⑨ Barium petroleum sulfonate: 10 parts Finally, fully stir and circulate to mix; keep the temperature of the mixed oil at 75°C, turn on the vacuum pump, and keep the vacuum at -0.096Mpa. After reacting for 0.5 hours, the sampling and analysis are qualified, and the finished product is obtained by metering, filtering and filling.

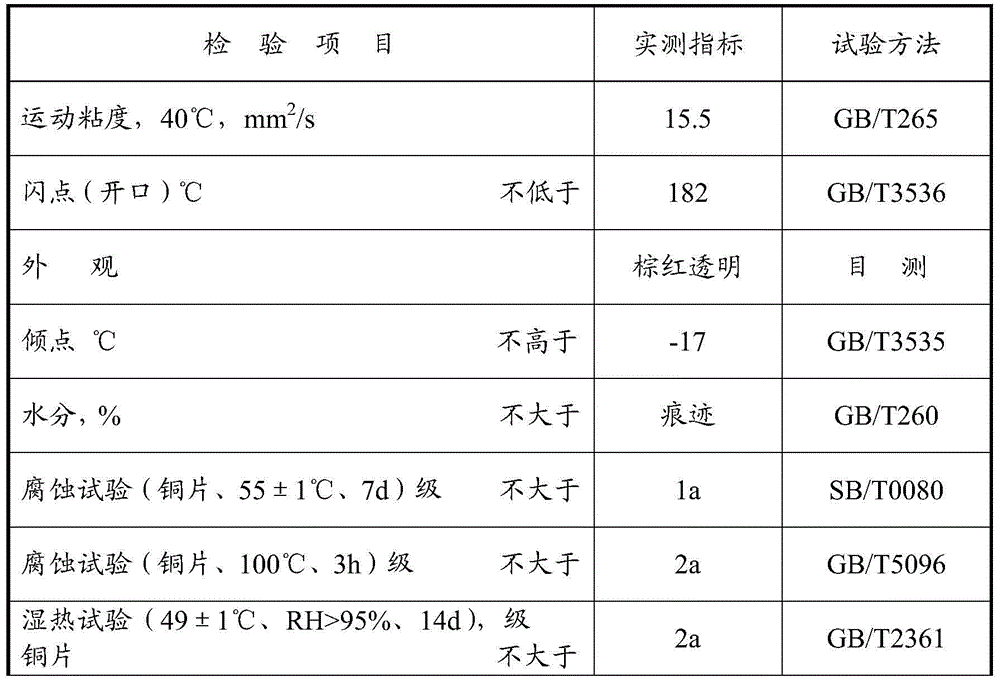

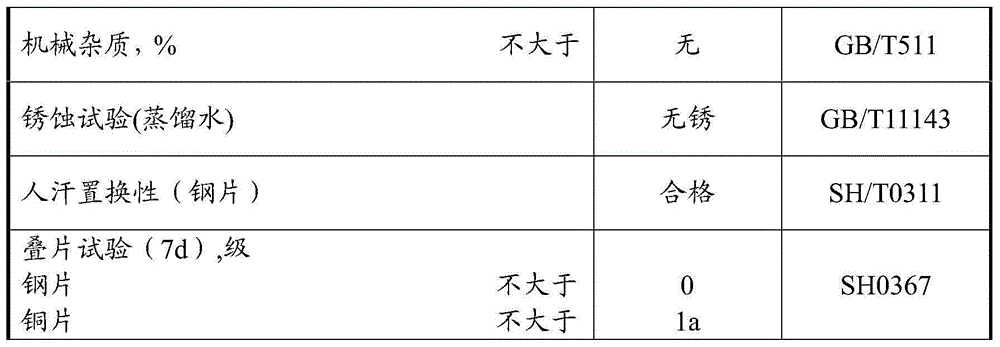

[0023] The product quality index prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com