Supramolecular clean fracturing fluid, and preparation method and application thereof

A technology for cleaning fracturing fluids and supramolecules, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of high concentration and high cost, and achieve high consistency and viscoelasticity, good rheology and portability sand effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a preparation method of supramolecular cleaning fracturing fluid, which comprises the following steps:

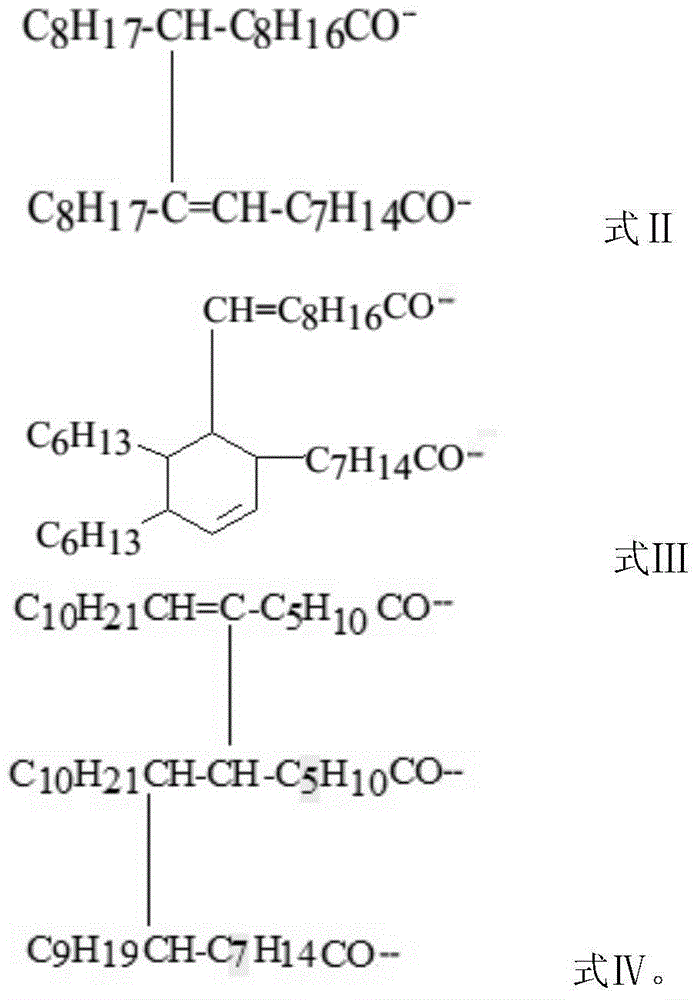

[0038] 1) Synthesis of dimer octadecylamide or dimerization and trimerization of mixed octadecylamide

[0039] Take high-purity dimer acid (the content of dimerized octadecanoic acid with C36>95%), or dimerization and trimerization mixed acid (the content of dimerized octadecanoic acid with C36 is 80%, and the carbon number is 80%). Trimeric octadecanoic acid whose number is C54 accounts for 20%) 100g was added to N,N-dimethyl-1,3-propanediamine (38.3g, 0.38mol), mixed evenly and heated to 160-180 ℃, keep warm for 3-8 hours, distill off the water generated by the reaction, and the reaction ends when the acid value is less than 6; distill off excess N,N-dimethyl-1,3-propylenediamine to obtain high-purity dimer Octadecylamide or dimeric, trimerized mixed octadecylamide.

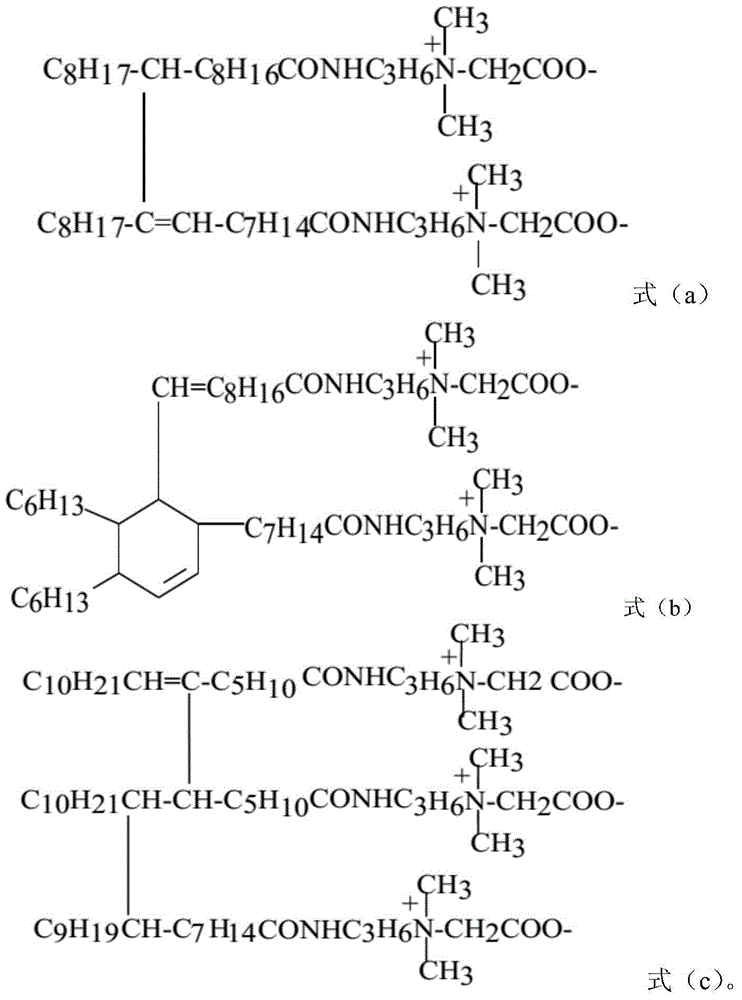

[0040] 2) Synthesis of Betaine Type Amphoteric Surfactant

[0041] Sod...

Embodiment 2

[0053] Present embodiment is on Harke RS6000 rheometer, in 100s -1 Under the shear rate, the viscosities of the liquids with different compositions were tested for viscosity at 70° C., and the results are shown in Table 1 (the concentration is the content of effective substances).

[0054] Table 1 Viscosity test results

[0055] serial number

[0056] It can be seen from Table 1 that in different series of homogeneous liquids, the viscosity obtained after compounding the amphoteric surfactant containing two or three hydrophilic groups and the anionic polymer containing hydrophobic groups is higher than that obtained when the two are used alone. The sum of the viscosities is higher, and compounding with anionic surfactants can further increase the viscosity.

Embodiment 3

[0058] In this embodiment, the dynamic viscoelasticity of the composite sample containing HMPAM and surfactant in Example 2 was tested on a Haake Mars rheometer, and the results are shown in Table 2.

[0059] Table 2 Viscoelastic properties (40°C, 0.01rad / s)

[0060] serial number

[0061] It can be seen from Table 2 that when the frequency is very low (0.1rad / s), the G' (storage modulus) of the composite sample (No. 1-3) is greater than G" (loss modulus), showing that it has a relatively high High viscoelastic properties are beneficial to sand-carrying performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com