High wet skid-resistant rubber composition for tyre surface

A rubber composition, anti-wet skid technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as easy to cause traffic accidents, sideslip, long braking distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

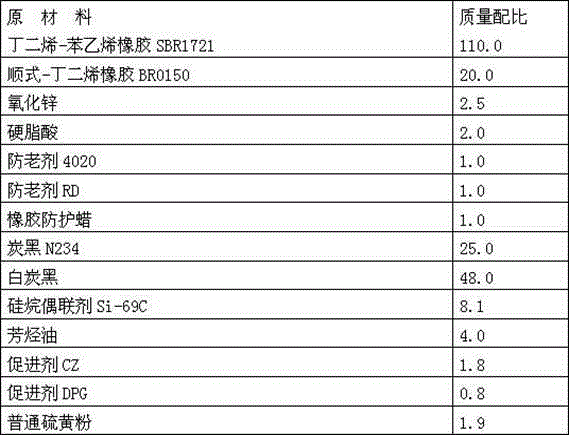

Embodiment 1

[0007]

[0008] In the present embodiment, the manufacture of the rubber composition takes the following processes:

[0009] The rubber material manufacturing is divided into three stages of mixing production, all of which adopt the intelligent mixing process of joint control of time and energy. Add butadiene-styrene rubber SBR1721, cis-butadiene rubber BR0150, carbon black N234 (3 / 4 of the total amount of carbon black N234), white carbon black, and silane coupling agent during the first stage of rubber mixing , stearic acid, aromatic oil; the second-stage rubber material uses the mixed rubber produced by the first-stage mixing as the masterbatch, and adds carbon black N234 (1 / 4 of the total amount of carbon black N234), zinc oxide, and anti-aging agent 4020 , anti-aging agent RD, rubber protective wax; the third stage of mixing is to use the mixed rubber produced in the second stage of mixing as the masterbatch, add accelerator CZ, DPG, and ordinary sulfur powder in the in...

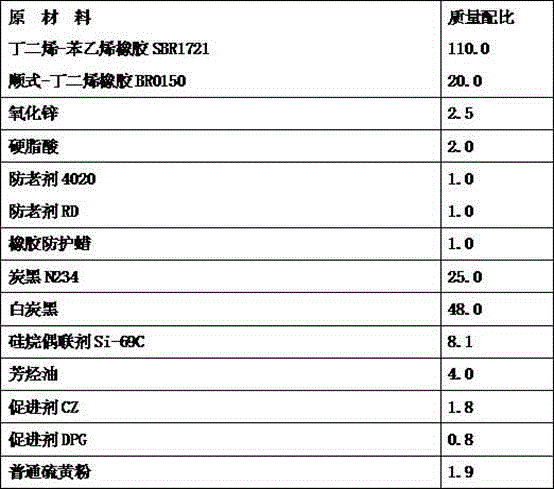

Embodiment 2

[0014]

[0015] In this embodiment, the same process as in Embodiment 1 is adopted to manufacture the rubber composition.

[0016] The performance test data of the rubber composition prepared using the formula of this embodiment is shown in the table below.

[0017]

[0018] Note: 2) Dynamic mechanical properties are measured by Mettler Toledo DMASDTA861e, shear test conditions: stress 10N, displacement 15μm, frequency 11HZ, initial temperature -50°C, end temperature 70°C, heating rate 3°C / min.

[0019] Using the rubber composition prepared in the above example, in the process of rubber mixing and extrusion, the rubber material does not suffer from "scorch", the production efficiency is high, the surface of the extruded tread is smooth, the cross section is compact, and the vulcanization process Normal, can fully meet the requirements of mass industrial production. The high-performance semi-steel radial tires produced have a short emergency braking distance, good handli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com