A modified calcium oxide cement concrete expansion agent and its preparation method

A technology of cement concrete and calcium oxide, which is applied in the field of building material concrete admixtures, can solve problems such as excessive consumption of expansion energy, and achieve the effects of reducing dosage, reducing cost, and high expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

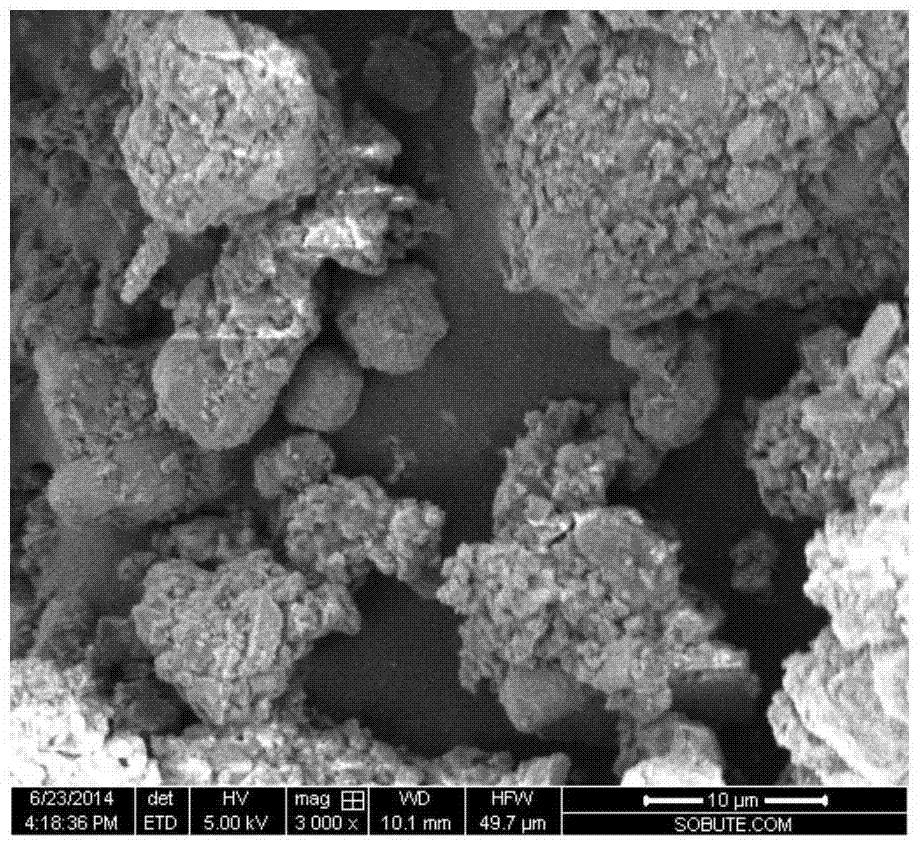

[0031] Limestone with a mass ratio of 90:10 is mixed with a composite mineralizer and then ground together by a ball mill to a fineness of 200m 2 / kg of raw meal powder, in which the compound mineralizer is gypsum. The ground raw meal powder was calcined at 1200°C, and kept at this temperature for 120 minutes (that is, the calcination time at 1200°C was 120 minutes). Fineness is 200m 2 / kg to obtain calcium oxide expansion clinker.

[0032] Add the prepared calcium oxide-based expanded clinker into the dichloromethane solution of DuPont ethylene-vinyl acetate copolymer 150, the mass ratio of calcium oxide to ethylene-vinyl acetate copolymer is 999:1, and remove after stirring for 5 minutes. Solvent dichloromethane, the obtained solid is ground to a specific surface area of 500m 2 / kg, sealed and packaged to obtain the modified calcium oxide cement concrete expansion agent 1 of the present invention.

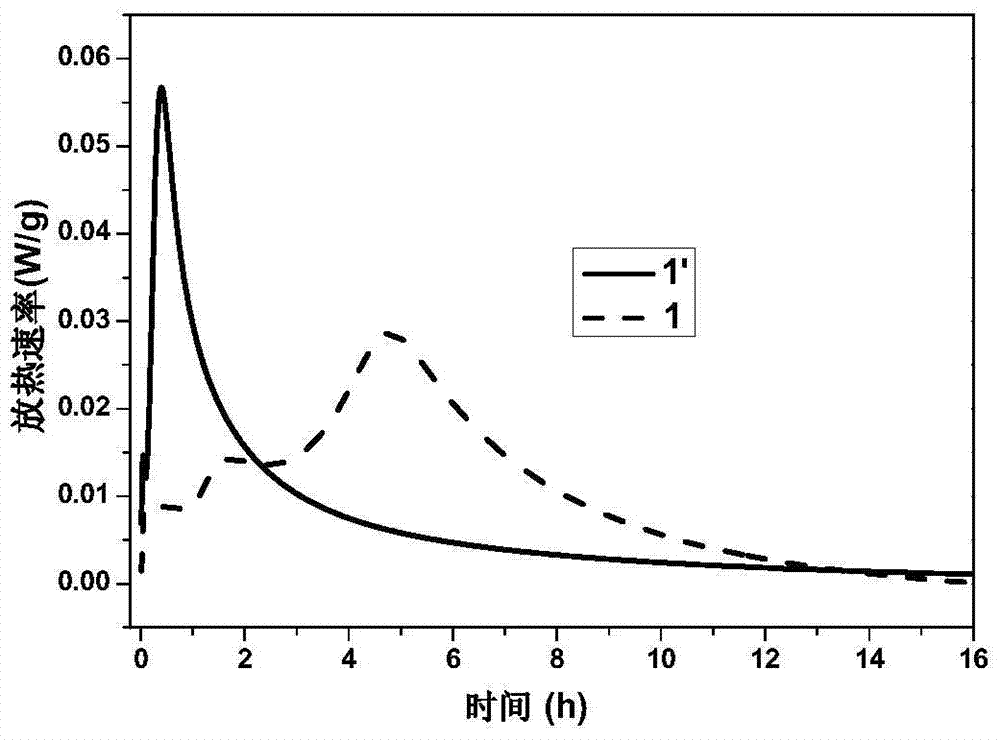

[0033] As a comparison, the above-mentioned calcium oxide-based expand...

Embodiment 2

[0035] Limestone with a mass ratio of 99:1 is mixed with a composite mineralizer and then ground together by a ball mill to a fineness of 100m 2 / kg of raw meal powder, wherein the composite mineralizer is gypsum / alumina / aluminum sulfate with a mass ratio of 50:25:25. The ground raw meal powder is calcined at 1350°C, and kept at this temperature for 60 minutes. After the heat preservation is completed, the fired sample is immediately taken out and quenched in the air, and ground to a fineness of 100m 2 / kg to obtain calcium oxide expansion clinker.

[0036] Add the prepared calcium oxide expansion clinker into the chloroform solution of Dupont ethylene-vinyl acetate copolymer 880 in the United States, the mass ratio of calcium oxide to ethylene-vinyl acetate copolymer is 99:1, and remove after stirring for 5 minutes. Solvent trichloromethane, the obtained solid is ground to a specific surface area of 600m 2 / kg, sealed and packaged to obtain the modified calcium oxide ceme...

Embodiment 3

[0039] Mix the limestone with a mass ratio of 95:5 and the composite mineralizer, and then grind them together with a ball mill to a fineness of 600m 2 / kg of raw meal powder, wherein the composite mineralizer is gypsum / aluminum sulfate / alumina with a mass ratio of 30:50:20. Calcinate the ground raw meal powder at 1450°C, and keep it at this temperature for 40 minutes. After the heat preservation is over, take out the fired sample and quench it in the air, and grind it to a fineness of 600m 2 / kg to obtain calcium oxide expansion clinker.

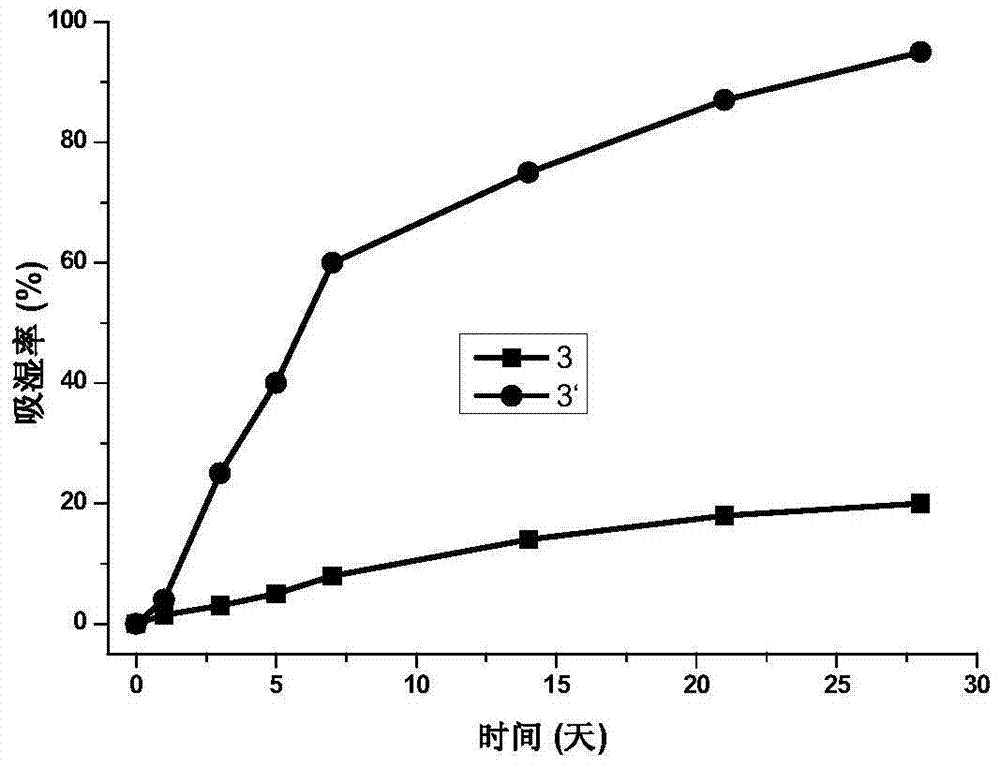

[0040] Add the prepared calcium oxide expansion clinker into the tetrahydrofuran solution of Sumitomo Chemical F2021, the mass ratio of calcium oxide to ethylene-vinyl acetate copolymer is 98:2, remove the solvent tetrahydrofuran after stirring for 15 minutes, and the obtained solid is ground to a specific surface area of 450m 2 / kg, sealed and packaged to obtain the modified calcium oxide cement concrete expansion agent 3 of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com