Online baking method for heat insulation type natural gas catalytic oxidation furnace

A technology of catalytic oxidation and oven method, applied in chemical instruments and methods, carbon monoxide, inorganic chemistry, etc., can solve the problems of reduced oxidation furnace efficiency, difficult temperature control, easy to generate stress, etc., to achieve controllable heating curve and avoid cracking , the effect of reducing the fluctuation range of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

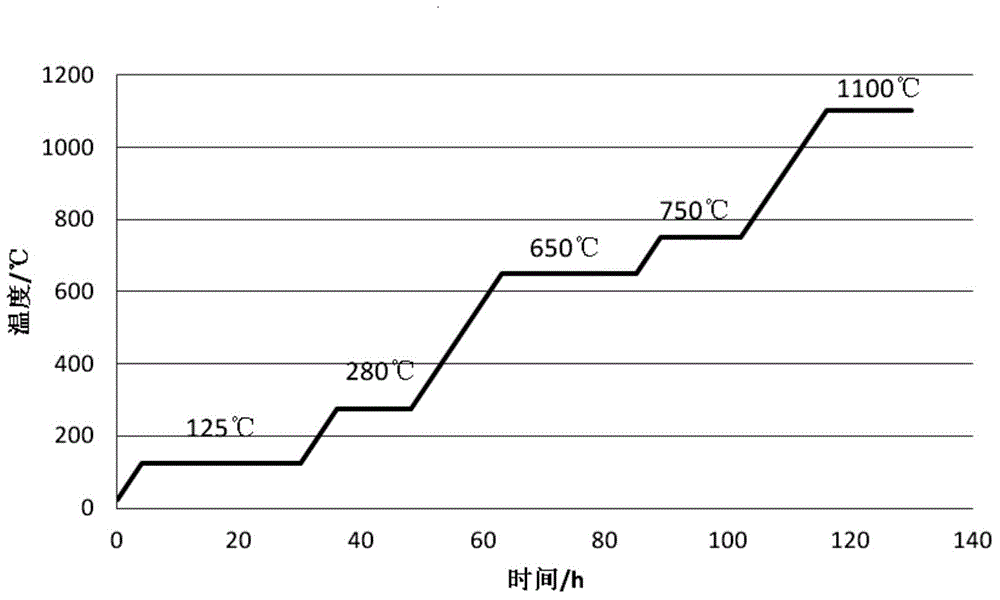

Embodiment 1

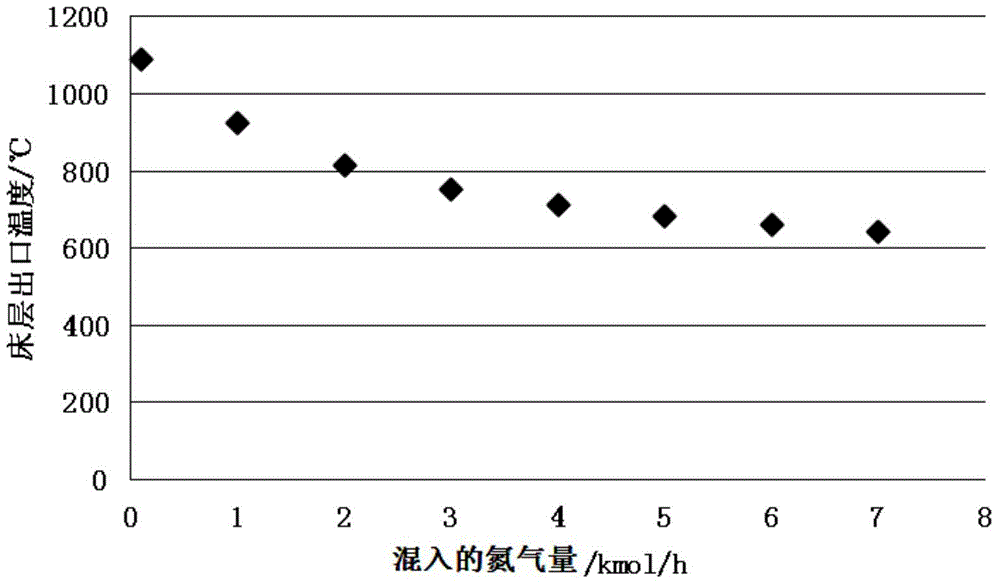

[0033] First, feed N into the natural gas catalytic oxidation furnace that has been dried and filled with precious metal catalysts. 2 , natural gas and oxygen, wherein, the natural gas contains >99.9% methane, and the natural gas flow rate is 1 kmol / h; the oxygen purity is >99.9%, and the oxygen flow rate is 0.6 kmol / h; the nitrogen gas purity is >99.9%, and the nitrogen gas flow rate is 7 kmol / h; , preheat the mixture formed by the above-mentioned nitrogen, natural gas and oxygen, and gradually increase the temperature of the mixture until it is heated to 300°C to trigger the catalytic oxidation reaction, then stop the preheating and gradually reduce the flow rate of the mixed nitrogen until the nitrogen The flow rate is reduced to 0, so that the reaction temperature rises at a heating rate that meets the requirements of the oven curve of the adiabatic refractory material in the natural gas catalytic oxidation furnace, and smoothly transitions to the normal operating condition...

Embodiment 2

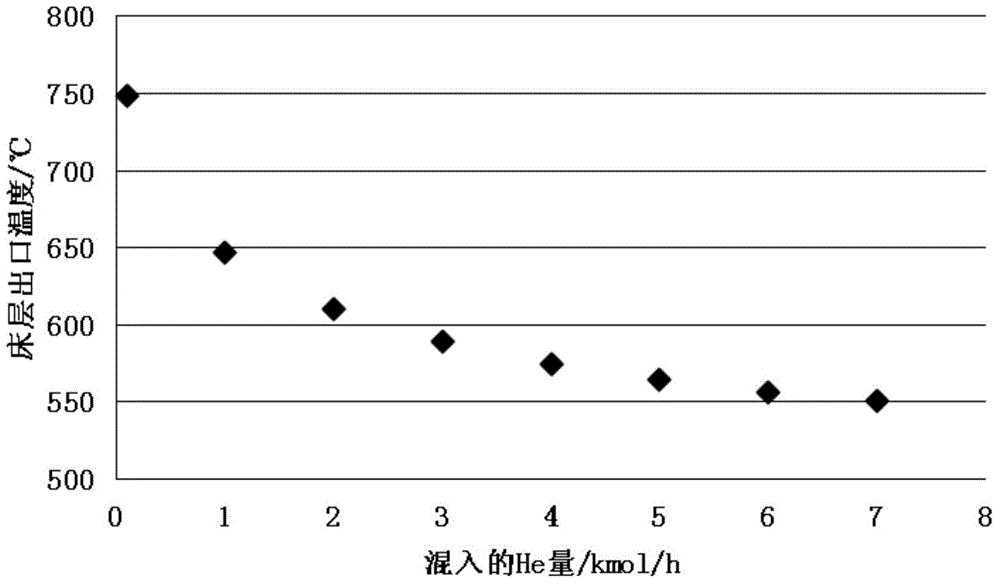

[0036] First, feed He, natural gas and oxygen into the natural gas catalytic oxidation furnace that has been dried and filled with precious metal catalysts, wherein the natural gas contains >99.9% methane, and the flow rate of natural gas is 1 kmol / h; the purity of oxygen is >99.9%, and the flow rate of oxygen 0.3kmol / h; the He purity is >99.9%, and the He flow rate is 7kmol / h; then, preheat the mixed gas made of the above-mentioned He, natural gas and oxygen, and gradually increase the temperature of the mixed gas until it is heated to 550 After the catalytic oxidation reaction is triggered at ℃, stop preheating and gradually reduce the mixed He flow rate until the He flow rate drops to 0, so that the reaction temperature rises at a heating rate that meets the requirements of the oven curve of the insulating refractory material in the natural gas catalytic oxidation furnace. Transition to the normal operating condition of 760°C, the oven curve of the insulating refractory mate...

Embodiment 3

[0039] First, feed CO into the natural gas catalytic oxidation furnace that has been dried and filled with precious metal catalysts. 2 , natural gas and oxygen, wherein, natural gas contains >99.9% methane, and the flow rate of natural gas is 1 kmol / h; the purity of oxygen is >99.9%, and the flow rate of oxygen is 0.4 kmol / h; CO 2 >99.9% pure, CO 2 The flow rate is 7kmol / h; then, for the above CO 2 , the mixture of natural gas and oxygen is preheated, and the temperature of the mixture is gradually increased until it is heated to 600°C to trigger the catalytic oxidation reaction, then the preheating is stopped and the mixed CO is gradually reduced. 2 flow, until CO 2 The flow rate is reduced to 0, so that the reaction temperature rises at a heating rate that meets the requirements of the oven curve of the adiabatic refractory material in the natural gas catalytic oxidation furnace, and smoothly transitions to the normal operating condition of 760 ° C. The oven of the adiabat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com