Two-speed hydraulic drive axle assembly for large grain combine harvester

A technology of combine harvester and drive axle assembly, which is applied in control devices, transportation and packaging, vehicle components, etc., can solve problems such as damage to gearbox gears, high physical energy consumption, and unreasonable speed matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

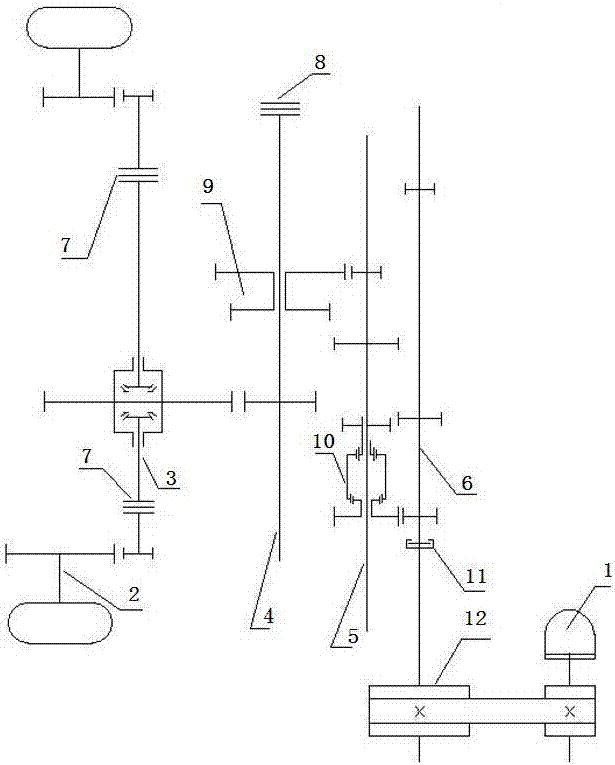

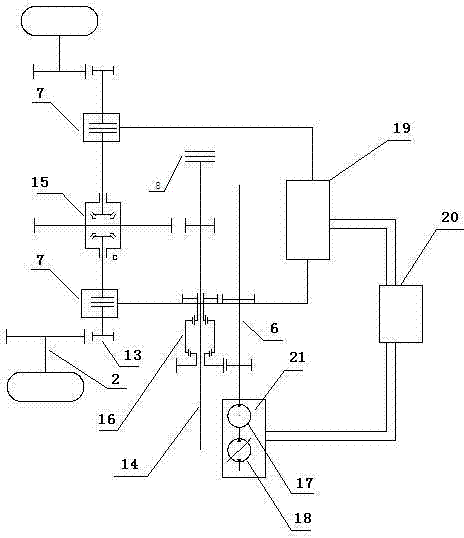

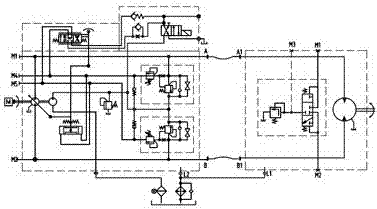

[0023] The drive axle assembly of the current large self-propelled grain combine harvester, such as figure 1 As shown, it usually includes engine 1, wheel-side reducer drive shaft 2, differential axle shaft 3, slip gear shaft 4, meshing sleeve gear shaft 5, input gear shaft 6, service brake 7, parking brake 8, Slip gear 9, meshing sleeve 10, clutch 11 and stepless torque increasing assembly 12, etc.; the transmission principle of the patent of the invention is as follows figure 2 Shown: the two-speed hydraulic drive axle assembly for the large and large grain combine harvester of the present invention includes a powered engine 1, a hydrostatic system 21 driven by the engine 1, and the hydrostatic system 21 includes a hydraulic variable pump 18 and a quantitative hydraulic The motor 17, the hydraulic variable pump 18 and the fixed hydraulic motor 17 are connected by hydraulic pipelines. The fixed hydraulic motor 17 is connected to the gearbox and the input gear shaft 6 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com