Timber internal micro blasting device

A wood interior and wood technology, applied in the field of wood interior micro-blasting devices, can solve the problems of slow piston moving speed, different impact force points, affecting blasting effect, etc., to achieve fast pressure relief speed, stable piston movement and blasting effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

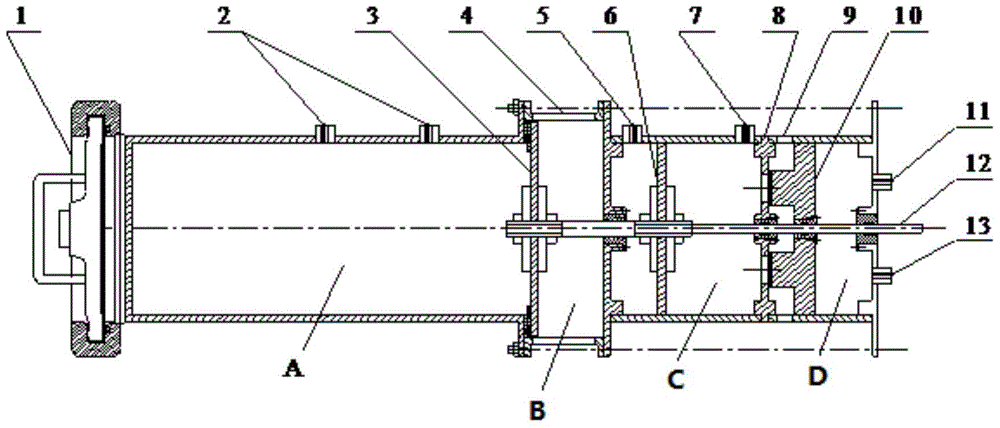

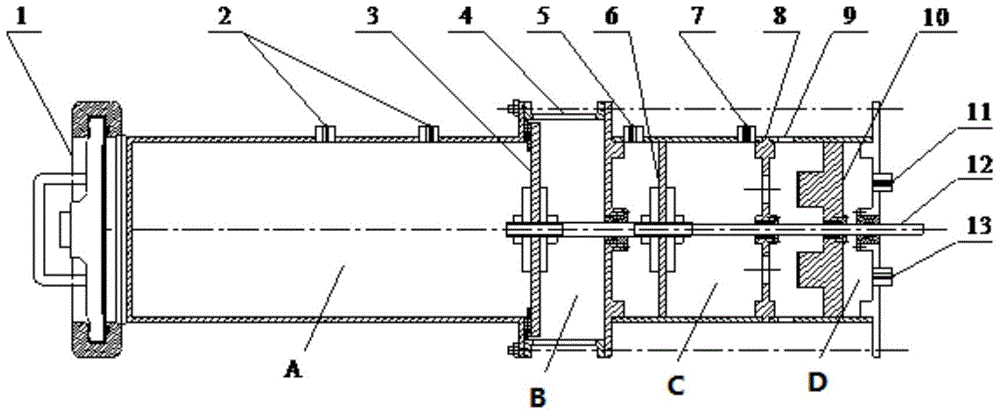

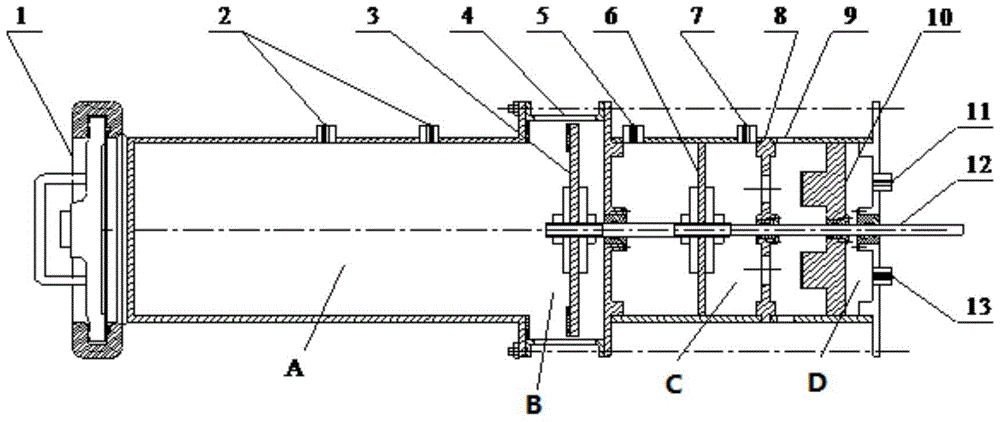

[0025] see figure 1 , The first embodiment of a wood internal micro-explosion device of the present invention includes a high-pressure cylinder A, a pressure relief cylinder B, a piston cylinder C, and an auxiliary piston cylinder D.

[0026] The high-pressure cylinder A is used to accommodate wood that needs to be micro-exploded. There is a high-pressure gas inlet 2 on the cylinder body, and the two ends are the feeding port and the pressure relief port; one end of the feeding port is provided with a quick-opening door 1, and the high-pressure The rear quick-opening door 1 in the cylinder A seals the feed inlet. The quick-opening door 1 can be a conventional door that can be quickly opened and closed; one end of the pressure relief port is provided with a cover plate 3 that can seal and open the pressure relief port. After the cover plate 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com