Novel corn husker

A peeling machine and corn technology, applied in harvesters, agricultural machinery and tools, threshing equipment, etc., can solve the problems of unreliability, manual mopping, unstable performance, etc., achieve reliable mechanical performance, improve work efficiency, and good peeling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

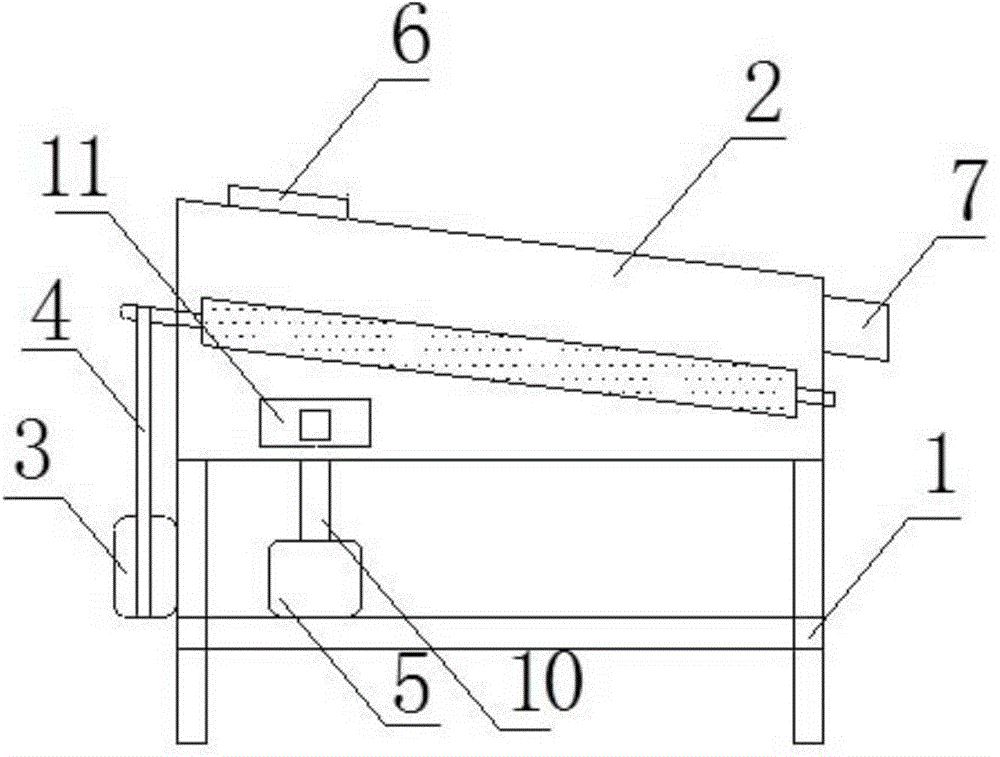

[0014] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

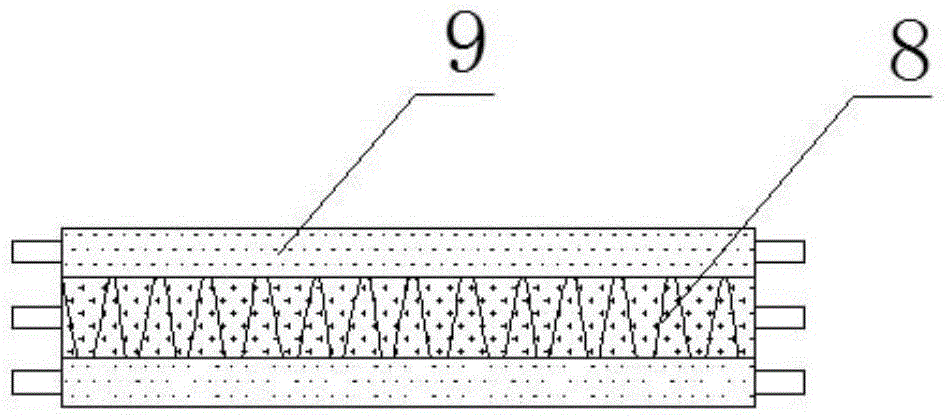

[0015] As shown in the figure: a new type of corn peeling machine is characterized in that it includes a frame 1, a peeling device 2, a motor 3, a transmission device 4 and a blower 5, and the peeling device 2 is installed above the frame 1, and the peeling device 2 is installed above the frame 1. The top left side of the device 2 is provided with an inlet 6, and the right side of the peeling device 2 is provided with an outlet 7, and the peeling device 2 is inclined downward from the inlet 6 to the outlet 7, and the peeling device 2 There is a main driving roller 8 and two auxiliary driving rollers 9 inside, the main driving roller 8 is a peeling steel roller, the auxiliary driving roller 9 is a peeling rubber roller, and the two auxiliary driving rollers 9 are located on the main driving roller 8 ends, the main drive roller 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com