Method for performing restoration on metal surface crack by utilizing wave key

A wave and crack technology, applied in the field of wave keys, can solve the problems affecting the normal use of the machine, damage, crack expansion, etc., and achieve the effects of reliable mechanical performance, short operation cycle and money saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

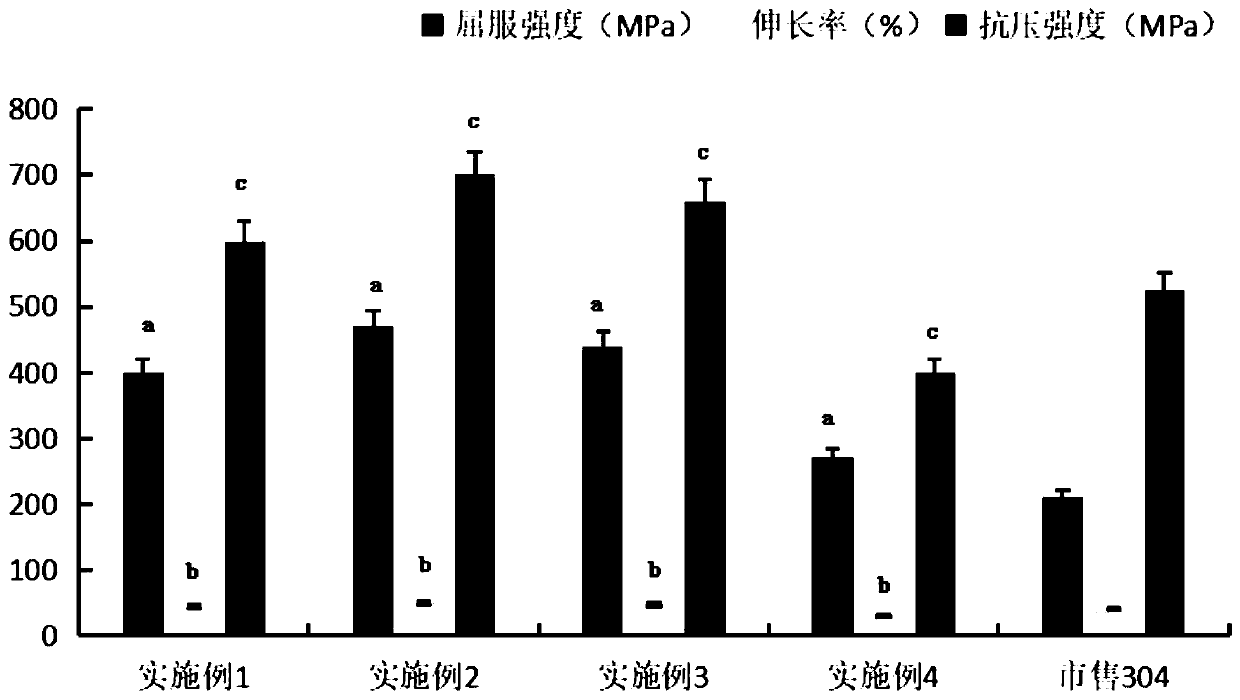

[0034] A high-strength, heat-resistant and corrosion-resistant stainless steel is composed of 0.5wt% nickel, 19wt% chromium, 1wt% manganese, and the rest is iron. The yield strength of the stainless steel is 400MPa, the elongation is 45%, and the compressive strength is 600MPa.

Embodiment 2

[0036] A high-strength heat-resistant and corrosion-resistant stainless steel, its composition is nickel 1.5wt%, chromium 21wt%, manganese 2wt%, the rest is iron, the yield strength of the stainless steel is 470MPa, the elongation is 52%, and the compressive strength is 700MPa.

Embodiment 3

[0038] A high-strength heat-resistant and corrosion-resistant stainless steel, its composition is nickel 1wt%, chromium 20wt%, manganese 1.5wt%, and the rest is iron. The yield strength of the stainless steel is 440MPa, the elongation is 49%, and the compressive strength is 660MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com