Processed cheese and its production method

A manufacturing method and cheese technology, applied in cheese substitutes, dairy products, phosphorus oxyacids, etc., can solve the problems of low flavor, hard texture, poor production efficiency, etc., and achieve excellent heat resistance, improved taste, good quality flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] 1.5 kg of Cheddar cheese (produced in New Zealand) and 1.5 kg of Gouda cheese (produced in Australia) were crushed and mixed. 3.0 kg of said mixed cheeses were put into the teapot type emulsification machine (made by Nichiraku Machinery Co., Ltd.). Water was added so that the moisture content reached 43%, and 60 g of molten salt A shown in Table 3 was added. Additionally, sodium bicarbonate was added to this mixture as a pH adjuster. Make the rotation speed of the mixing paddle of the emulsifier reach 150rpm, blow the steam to the casing, and at the same time, heat and process the processed cheese. When the temperature of the cheese reaches 85°C, stop heating and stirring, and then take a sample and produce processed cheese by cooling. cheese (implementation product 1). Furthermore, the pH of the obtained processed cheese was 6.1.

[0127] 【table 3】

[0128] Main component of molten salt that imparts heat resistance to processed cheese and turbidity of 1.0% aqueou...

Embodiment 2

[0131] 1.5 kg of Cheddar cheese (produced in New Zealand) and 1.5 kg of Gouda cheese (produced in Australia) were crushed and mixed. 3.0 kg of said mixed cheeses were put into the teapot type emulsification machine (made by Nichiraku Machinery Co., Ltd.). Water was added so that the moisture content reached 43%, and 60 g of molten salt B shown in Table 3 was added. Additionally, sodium bicarbonate was added to this mixture as a pH adjuster. Make the rotation speed of the mixing paddle of the emulsifier reach 150rpm, blow the steam to the casing, and at the same time, heat and process the processed cheese. When the temperature of the cheese reaches 85°C, stop heating and stirring, and then take a sample and produce processed cheese by cooling. cheese (implementation product 2). Furthermore, the pH of the obtained processed cheese was 5.9.

Embodiment 3

[0133] 1.5 kg of Cheddar cheese (produced in New Zealand) and 1.5 kg of Gouda cheese (produced in Australia) were crushed and mixed. 3.0 kg of said mixed cheeses were put into the teapot type emulsification machine (made by Nichiraku Machinery Co., Ltd.). Water was added so that the moisture content reached 43%, 30 g of molten salt A shown in Table 3 was added, and 30 g of sodium diphosphate was added. Additionally, sodium bicarbonate was added to this mixture as a pH adjuster. Make the rotation speed of the mixing paddle of the emulsification machine reach 150rpm, blow the steam to the casing, and at the same time, heat, and when the temperature of the processed cheese reaches 85°C, stop heating and stirring, after that, take a sample, and manufacture the processed cheese by cooling. Cheese (implementation product 3). Furthermore, the pH of the obtained processed cheese was 5.9.

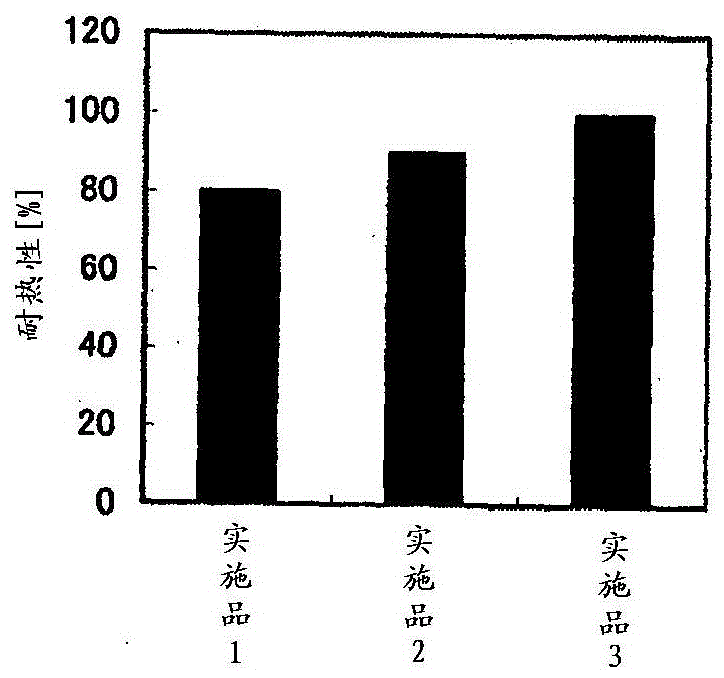

[0134] Regarding the examples 1 to 3, the heat resistance evaluation results are shown in f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com