Dynamic wireless power supply system used for electric vehicle and based on parallel multistage composite resonant structures and power supply method realized by adopting system

A technology of wireless power supply and resonant structure, applied in electric vehicles, electromagnetic wave systems, battery circuit devices, etc., can solve the problems of uneven mutual inductance of long-distance power supply coupling mechanism and electromagnetic radiation of pedestrians passing by, to avoid changes in power transmission efficiency and ensure Effects of stability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

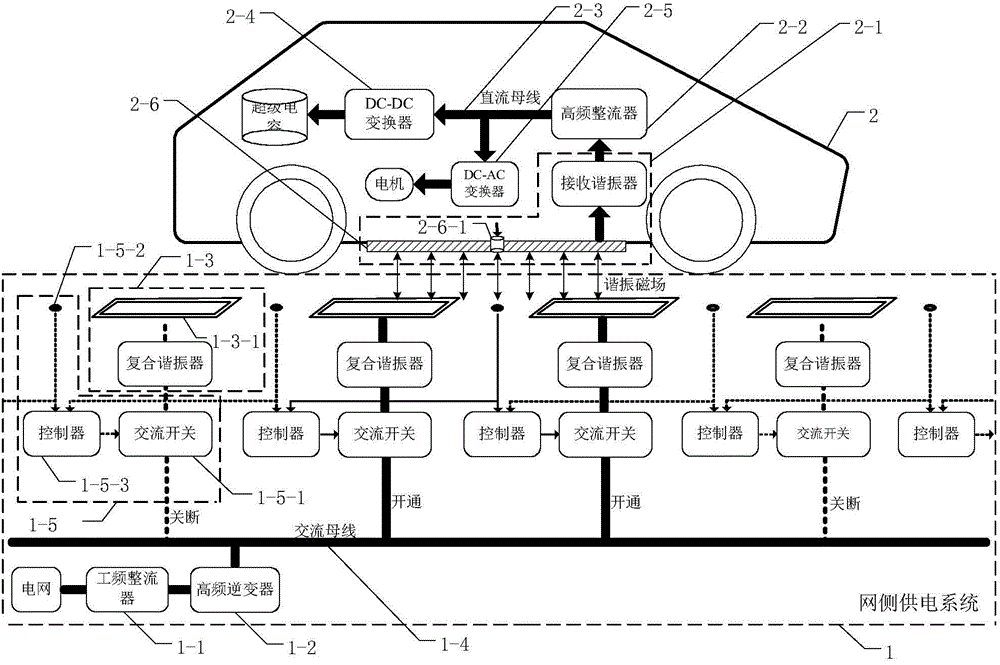

[0065] Specific implementation mode one: see figure 1 Describe this embodiment, the electric vehicle dynamic wireless power supply system based on multi-stage composite resonance structure parallel connection described in this embodiment, it includes a grid-side power supply system 1 and an electric vehicle-side power receiving system 2;

[0066] The grid side power supply system 1 is used to wirelessly supply power to the electric vehicle side power receiving system 2;

[0067] The grid side power supply system 1 includes a power frequency rectifier 1-1, a high frequency inverter 1-2, an n-level composite resonant circuit 1-3 and a position detection and control circuit 1-5;

[0068] The electric energy output by the power grid is sent to the high-frequency inverter 1-2 through the power frequency rectifier 1-1, and the n-level composite resonant circuit 1-3 is connected in parallel on the AC bus 1-4 output by the high-frequency inverter 1-2; n is a positive integer greater ...

specific Embodiment approach 2

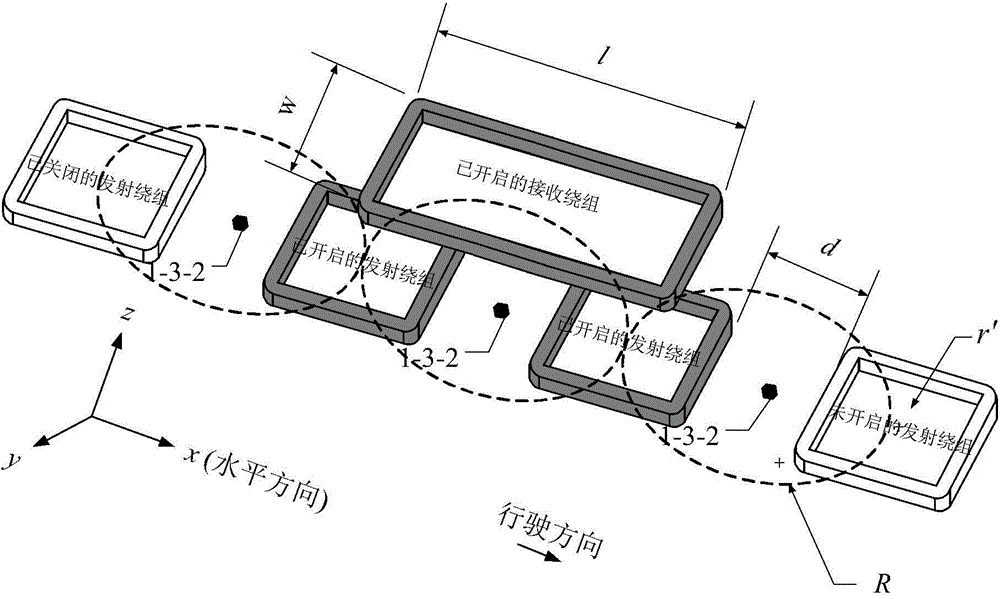

[0088] Specific implementation mode two: seefigure 1 Describe this embodiment. The difference between this embodiment and the electric vehicle dynamic wireless power supply system based on multi-stage composite resonant structure parallel connection described in Embodiment 1 is that the transmitting winding 1-3-1 is square and is wound by Litz wire A multi-turn coil is made, and there is no magnetic core on the transmitting winding 1-3-1.

specific Embodiment approach 3

[0089] Specific implementation mode three: see figure 1 Describe this embodiment. The difference between this embodiment and the electric vehicle dynamic wireless power supply system based on multi-stage composite resonance structure parallel connection described in the first embodiment is that the magnetic sensor 1-3-2 is a high-sensitivity three-axis magnetic sensor. sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com