Method for preparing silicon-carbon composite anode and lithium ion battery

A negative electrode, silicon-carbon composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve volume expansion and other problems, achieve the effects of increasing energy density, avoiding capacity loss, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

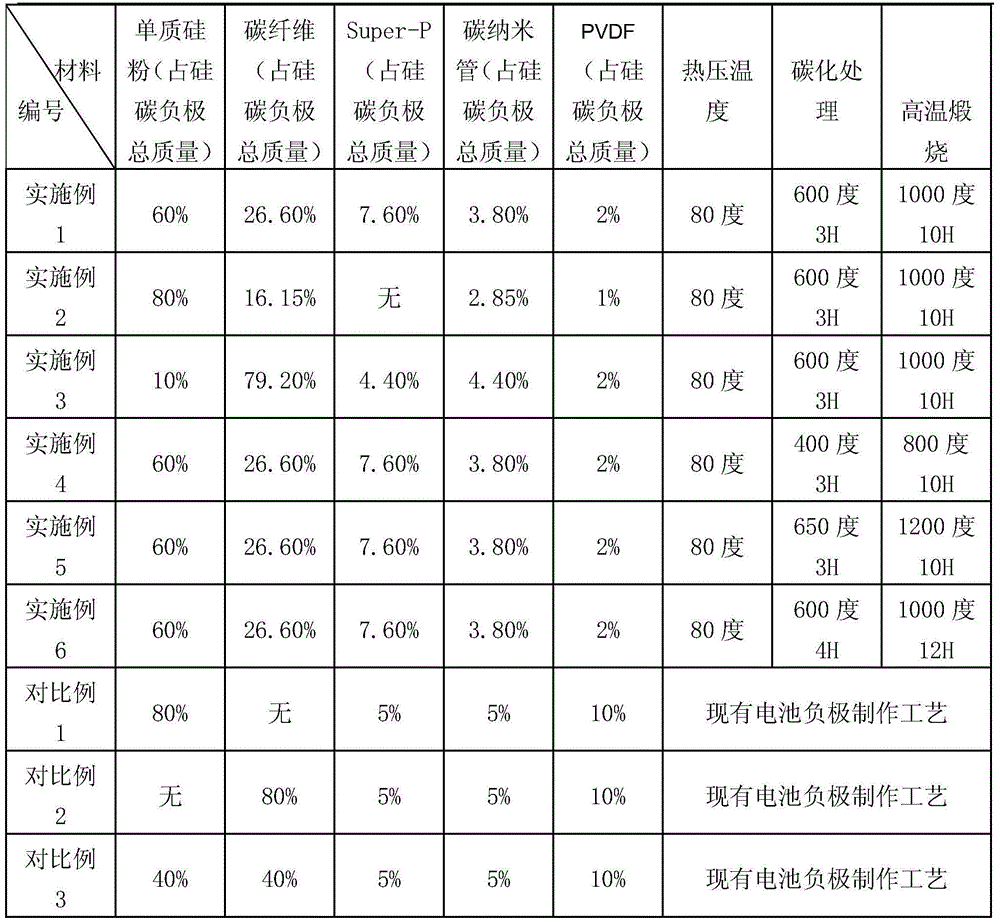

[0030] The preparation process of the silicon-carbon composite negative electrode of the present invention is as follows:

[0031] Thoroughly mix and disperse the silicon source and the carbon source, add a binder and a solvent to prepare a negative electrode slurry with a solid content of 10%-80%, and the solvent is deionized water or NMP solution; wherein,

[0032] The silicon source is elemental silicon, the particle size distribution of the elemental silicon is 100nm-80um, the purity of the elemental silicon is above 99.9%, and the silicon source accounts for 10%-80% of the total mass of the silicon-carbon negative electrode;

[0033] The carbon source includes a carbon negative electrode material and a conductive agent, the carbon negative electrode material is one or more of carbon fiber, graphite and mesocarbon microspheres, and the conductive agent is a carbon black conductive agent, graphite conductive agent and graphite One or more of alkenes, the carbon negative ele...

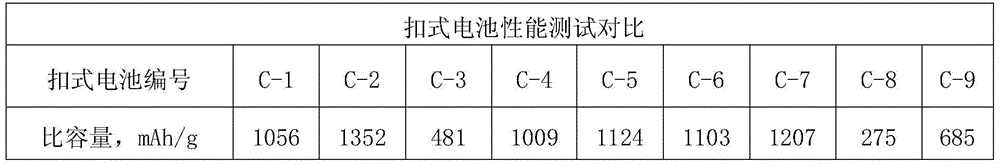

Embodiment 1

[0064] (1) Preparation of negative electrode

[0065] 1200g of elemental silicon powder (accounting for 60% of the total mass of silicon-carbon negative electrode, particle size distribution of 500nm-15um, and a purity of 99.999%), 760g of carbon source (accounting for 38% of the total mass of silicon-carbon negative electrode) and 40g of PVDF (accounting for 2% of the total mass of the silicon-carbon negative electrode, Solvay PVDF5130) was prepared into a slurry with a solid content of 60%, and the balance was NMP solvent, wherein the carbon source was 532g of carbon fiber (accounting for 26.6% of the total mass of the silicon-carbon negative electrode, Qingdao Taineng Co., Ltd.), 152g of Super P (accounting for 7.6% of the total mass of the silicon carbon negative electrode, Temegao Graphite Co., Ltd.) and 76g of carbon nanotubes (accounting for 3.8% of the total mass of the silicon carbon negative electrode, Beijing Tiannai Technology Co., Ltd.) mixture;

[0066] The prep...

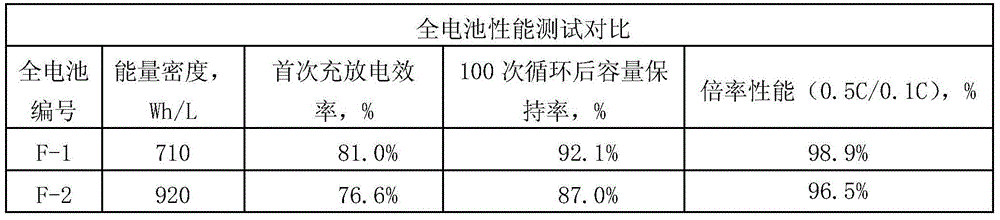

Embodiment 2

[0077] The silicon carbon negative electrode was prepared according to the same method as in Example 1.

[0078] The difference is that 1600g of silicon silicon powder, 380g of carbon source and 20g of PVDF were prepared into a slurry with a solid content of 60%, wherein the carbon source was a mixture of 323g of carbon fiber and 57g of carbon nanotube.

[0079] Battery assembly was carried out with reference to the battery assembly of Example 1, and a button-type lithium-ion battery C-2 and a stacked-type lithium-ion battery F-2 were produced. Wherein the weight of the negative electrode active material in the laminated battery is 1.8g, and the weight of the positive electrode active material is 16.27g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com