Condensation type halogen lamp assembly

A technology of halogen lamps and components, which is applied to the components of lighting devices, electric light sources, incandescent gas lamps, etc., and can solve the problems of not being able to make full use of light energy and not being able to illuminate the aisle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention can be further understood through the specific examples of the present invention given below, but they are not intended to limit the present invention. Some non-essential improvements and adjustments made by those skilled in the art based on the above content of the invention are also deemed to fall within the protection scope of the present invention.

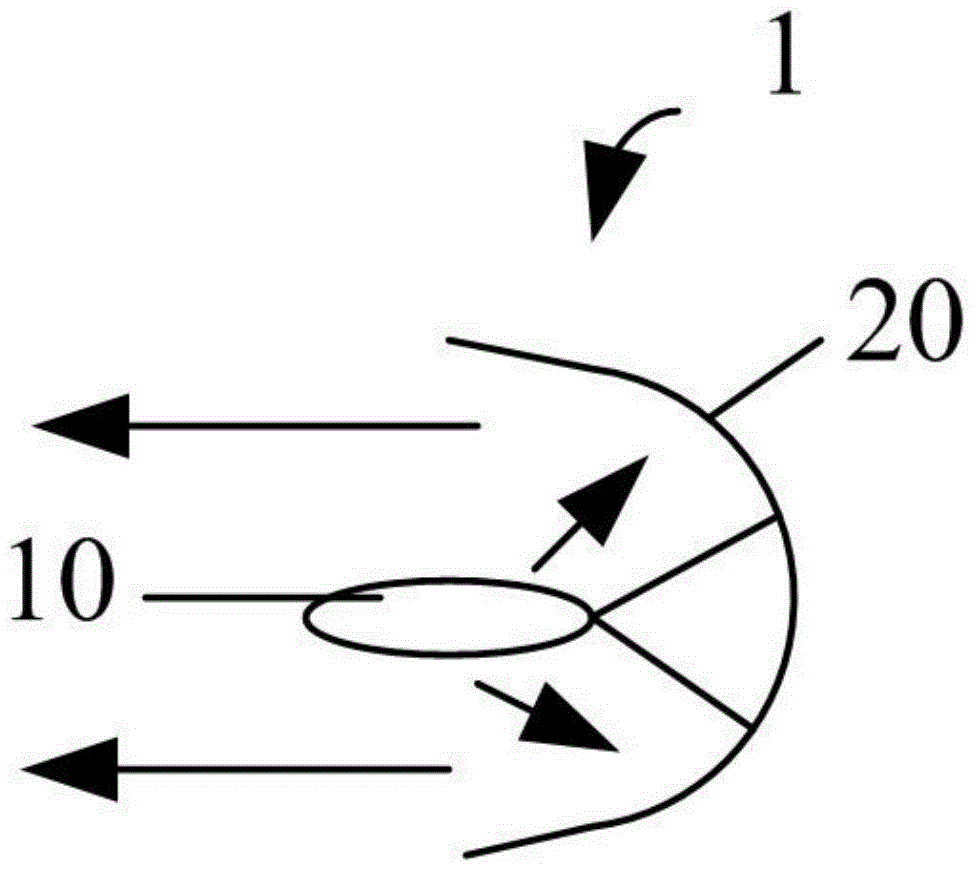

[0012] see figure 1 . In an embodiment of the present invention, a concentrating halogen lamp assembly 1 includes a halogen lamp body 10 . The halogen lamp assembly 1 includes a concave lens-shaped component 20 capable of reflecting light. The halogen lamp body 10 is disposed inside the concave lens-shaped component 20 .

[0013] The halogen lamp body 10 is arranged at the focal point of the concave lens-shaped part 20, and with this structure, the light is more concentrated.

[0014] The concave lenticular member 20 has mercury plating inside. Practice has proved that the reflective effect of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com