Upper end surface of tapered spring rubber body, and method and product for preventing folds and cracks

A conical spring and rubber body technology, which is applied in springs, transportation and packaging, railway car body parts, etc., can solve the problems that it is difficult to meet the multiple stiffness changes of the locomotive, and the rubber body is wrinkled and cracked, so as to prevent the locomotive from derailment and cracking , Increase the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

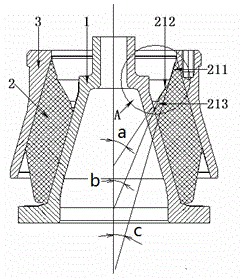

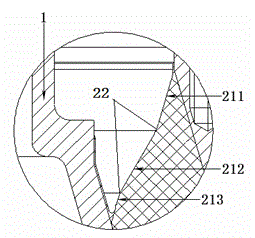

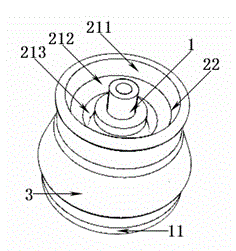

[0040] Such as figure 1 - As shown in 3, a conical spring includes an inner cone 1, a rubber body 2 and an outer cone 3. The lower end of the inner cone 1 extends outward to form an annular inner cone boss 11. The upper end surface 21 of the rubber body 2 is a three-segment multi-segment downhill structure, which are respectively the first circular straight segment 211, the second circular straight segment 212 and the third circular straight segment 213. The circular fillet section 22 is used for transition. In this embodiment, the fillet radii of the two circular fillet segments 22 on the upper end surface of the rubber body 2 are both 4-8 mm. The rubber body 2 surrounds the periphery of the inner cone 1 , and the outer cone 3 surrounds the periphery of the rubber body 2 . The inner cone 1 and the outer cone 3 are metal parts, and the inner cone 1, the outer cone 3 and the rubber body 2 are vulcanized into a whole through the adhesive at a certain temperature and pressure. ...

Embodiment 2

[0050] The structure is roughly the same as that of Embodiment 1, but the upper end surface of the rubber body 2 is not a gentle straight-line edge transition, but a gentle curved edge transition, and the upper end of the rubber body 2 is four sections of annular straight sections 21 and three sections of annular circles. Corner section 22, and the lower end of rubber body 2 is three sections of circular straight section 21 and two sections of annular round corner section 22. Changing the number of segments of the annular straight section 21 can change the number of times the conical spring becomes stiff, that is to say, the number of times of the stiffness of the conical spring can be changed by adjusting the number of ring straight segments 21 . Increasing or reducing the number of annular straight sections 21 can still make the upper and lower ends of the rubber body 2 wrinkle-free and always maintain a smooth shape when the conical spring is from no load to the maximum vert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com