Sewage drainage device

A technology for sewage devices and sewage pits, which is applied to water supply devices, drainage structures, waterway systems, etc., can solve the problems of poor anti-pollution ability, low degree of automation, easy backflow of oil, etc., and achieves easy maintenance, reliable performance, and application range. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

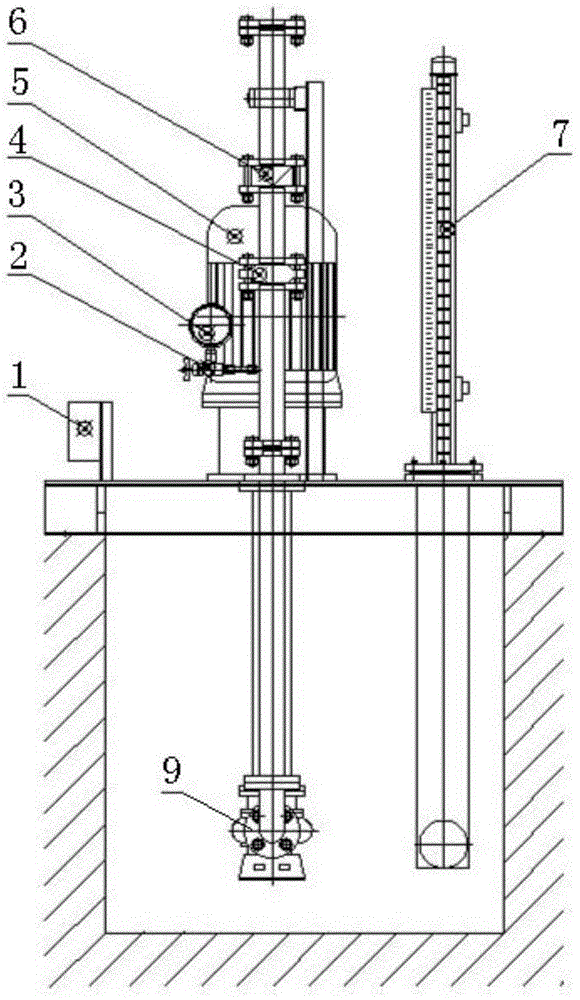

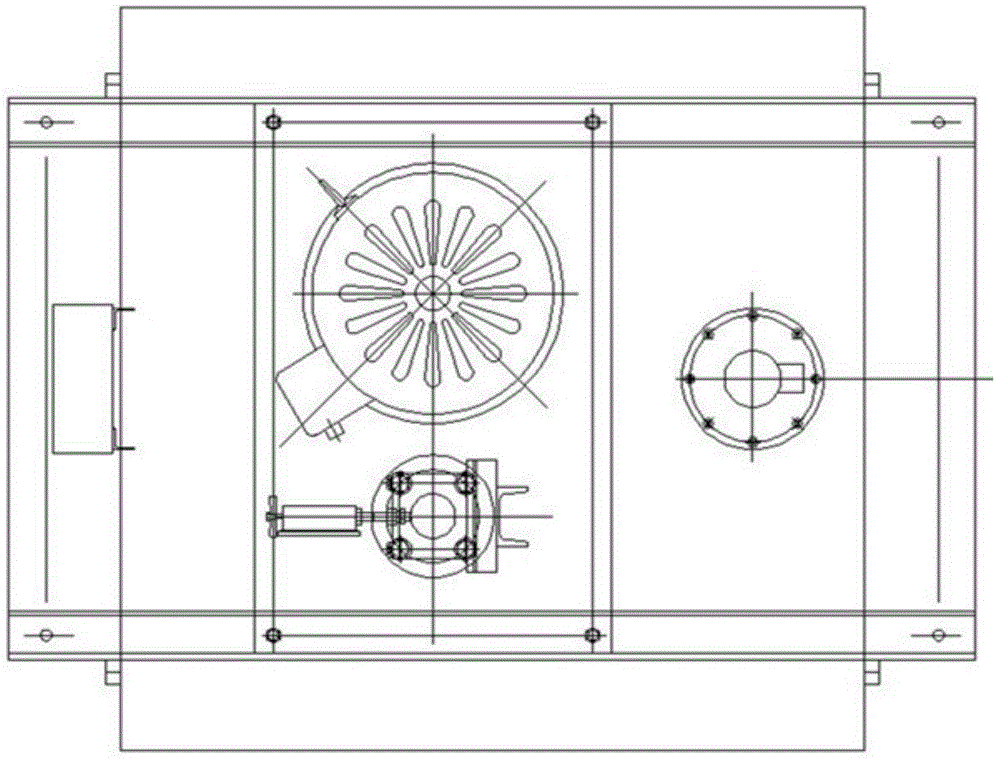

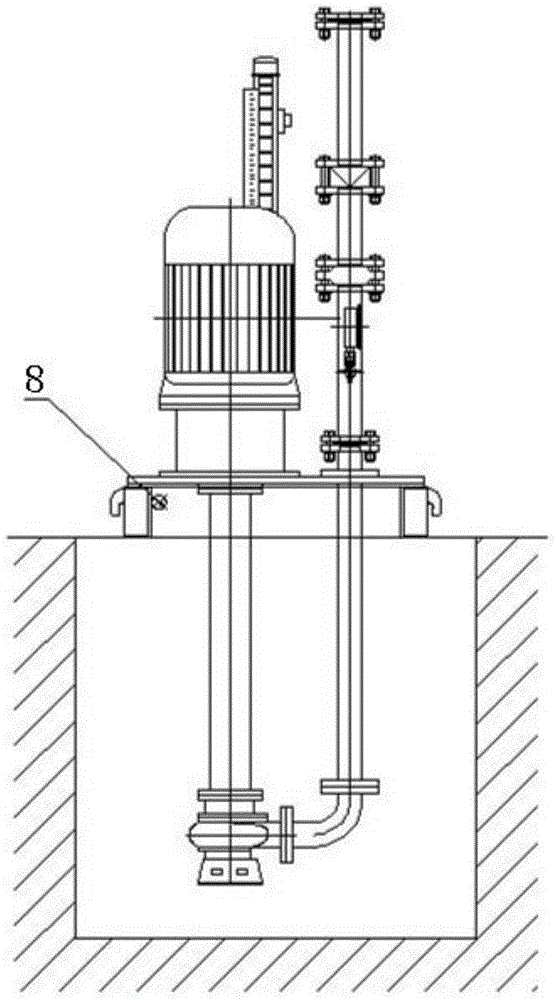

[0012] Such as Figure 1-Figure 4 As shown, the sewage discharge device includes a motor 5, a check valve 6, a magnetic float level gauge 7, a support 8 and a submerged centrifugal pump 9, the support 8 is installed above the sump, and the upper middle part of the support 8 is installed There is a motor 5, and the motor 5 is connected to the submerged centrifugal pump 9 located in the sewage pit. The submerged centrifugal pump 9 is connected to the butterfly valve 4 and the check valve 6 in sequence through the pipeline through the support 8, and the butterfly valve 4 and the support 8 A pressure gauge switch 2 and a pressure gauge 3 are installed on the pipeline. The pressure gauge 3 is a shock-resistant pressure gauge. The terminal box 1 is installed on the upper side of the support 8, and the magnetic float level gauge 7 is installed on the other side. The bottom of the position meter 7 passes through the support 8 and is located in the sewage pit; the present invention has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com