A fast-changing target single-sided reciprocating continuous coating magnetron sputtering roll-to-roll coating machine

A magnetron sputtering and coating machine technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of continuous sputtering three-layer dielectric film, sputtering time and sputtering atmosphere , Electricity and other resources use more problems, to achieve the effect of simplifying electrical control devices and procedures, saving time and energy, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

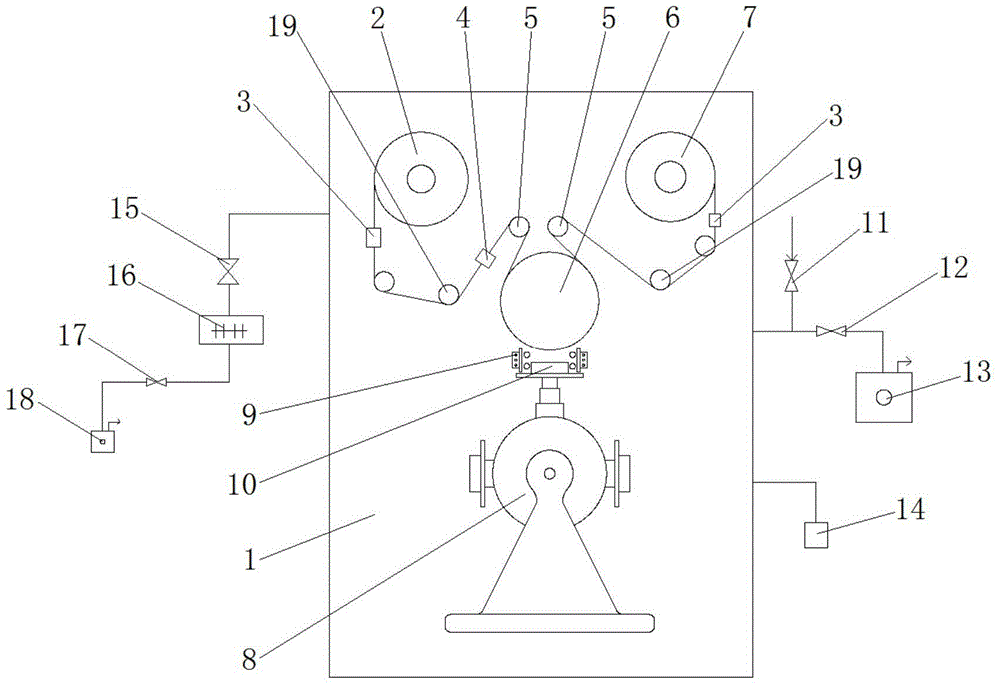

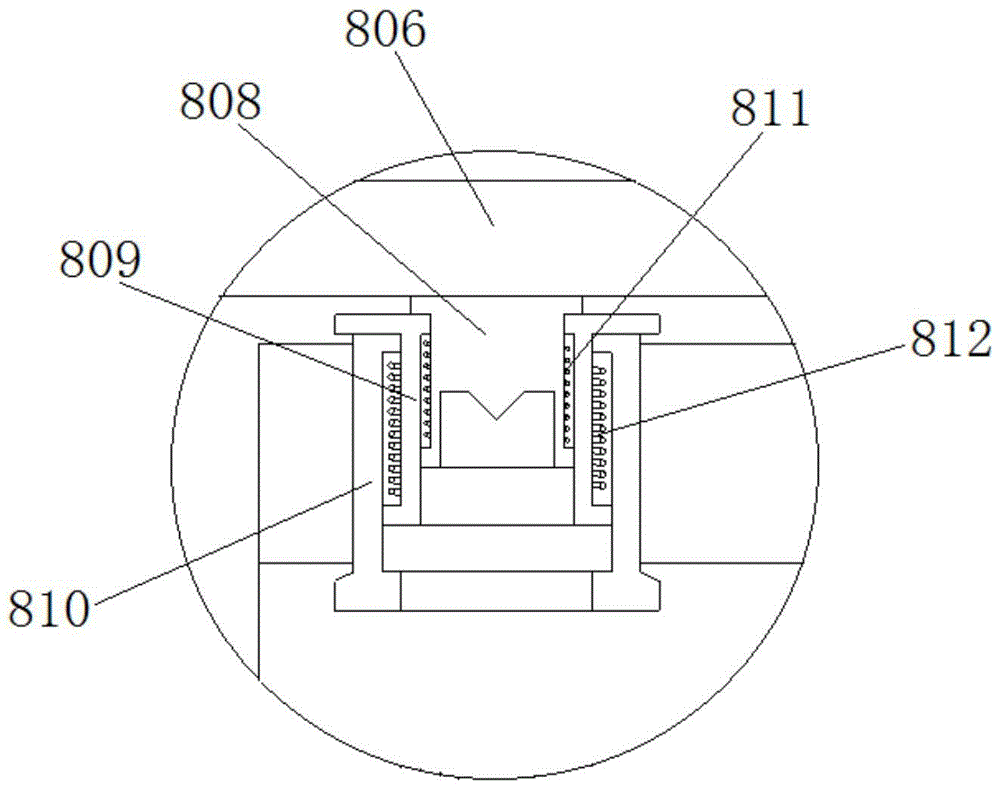

[0036] like figure 1 As shown, a magnetron sputtering roll-to-roll coating machine for rapid target-changing single-sided reciprocating continuous coating in this embodiment includes a vacuum chamber 1, an unwinding mechanism 2, a cooling roller 6, and a winding mechanism sequentially arranged in the vacuum chamber 1 7, and the cathode cell 9 located below the cooling roller 6, also includes a deviation correction device 3 and a return conversion target device 8 located below the cathode cell 9, and the base tape between the unwinding mechanism 2 and the winding mechanism 7 passes through the reversing roller 5 Covered on the cooling roller 6 after reversing, and the base belt is also provided with a tension roller 19, the tension roller 19 is connected with the torque motor for real-time adjustment of the tension of the base belt, the unwinding mechanism 2, the winding mechanism 7 and the cooling The three rollers 6 are synchronously linked. During the coating process, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com