Method for preparing reduced graphene oxide/CoFe2O4/Ag composite wave-absorbing material

A composite wave-absorbing material, cofe2o4 technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor performance, complicated process, and harsh conditions of composite materials, and achieve good wave-absorbing performance, simple preparation process, The effect achieved by the preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

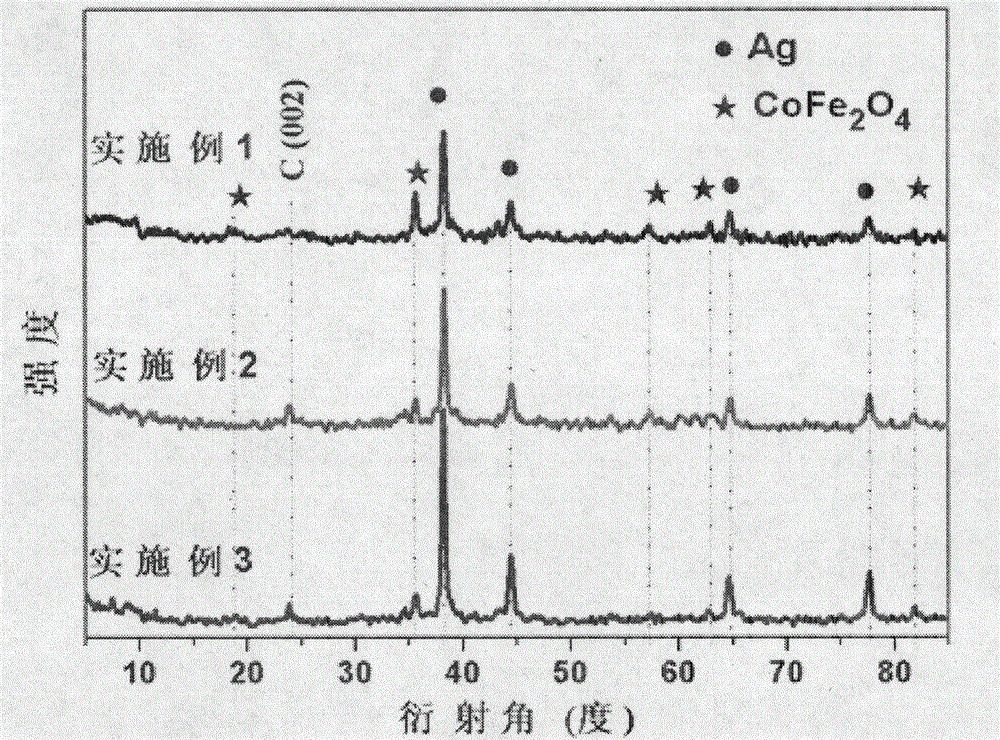

Embodiment 1

[0021] 1. Prepare a GO water solution with a concentration of 0.67 mg / ml, and prepare a 1 mol / L NaOH aqueous solution for later use;

[0022] 2. According to the mass ratio of GO:Co(NO 3 ) 2 ·6H 2 O:Fe(N0 3 ) 3 ·9H 2 O=1:1.24:3.42, weigh 124mg Co(NO 3 ) 2 · 6H 2 O and 342mgFe(NO 3 ) 3 ·9H 2 O, added to 150ml GO aqueous solution, after stirring for 30min, NaOH solution was added dropwise to adjust the pH of the mixture to 11;

[0023] 3. Add the above mixture into a hydrothermal kettle lined with polytetrafluoroethylene, and react at 180°C for 12 hours;

[0024] 4. The obtained precipitate was washed alternately with deionized water and absolute ethanol to pH=7, and the obtained RGO / CoFe 2 O 4 The precipitate was dispersed in 150ml of deionized water, according to the mass ratio of GO:AgNO 3 =1:0.63 Weigh 63mg AgNO 3 , added to the above mixture, stirred for 20min, according to the mass ratio of GO:NaBH 4 =1:5, weigh 500mgNaBH 4 Dissolved in 20ml of water, drop...

Embodiment 2

[0029] 1. Prepare a GO aqueous solution with a concentration of 0.67 mg / ml, and prepare a 1 mol / L NaOH aqueous solution for later use;

[0030] 2. According to the mass ratio of GO:Co(NO 3 ) 2 ·6H 2 O:Fe(NO 3 )3· 9 H 2 O=1:1.24:3.42, weigh 124mgCo (NO 3 ) 2 ·6H 2 O and 342mgFe(N0 3 )3 9H 2 O, added to 150ml GO aqueous solution, after stirring for 30min, NaOH solution was added dropwise to adjust the pH of the mixture to 11;

[0031] 3. Add the above mixture into a hydrothermal kettle lined with polytetrafluoroethylene, and react at 180°C for 12 hours;

[0032] 4. The obtained precipitate was washed alternately with deionized water and absolute ethanol to pH=7, and the obtained RGO / CoFe 2 O 4 The precipitate was dispersed in 150ml of deionized water, according to the mass ratio of GO:AgNO 3 =1:0.95 Weigh 95mg AgNO 3 , add the above mixed liquid, stir for 20min, according to the mass ratio GO:NaBH 4 =1:5, weigh 500mgNaBH 4 Dissolved in 20ml of water, dropped into...

Embodiment 3

[0036] 1. Prepare a GO aqueous solution with a concentration of 0.67 mg / ml, and prepare a 1 mol / L NaOH aqueous solution for later use;

[0037] 2. According to the mass ratio of GO:Co(NO 3 ) 2 ·6H 2 O:Fe(NO 3 ) 3 ·9H 2 O=1:1.24:3.42, weigh 124mg Co(NO 3 ) 2 ·6H 2 O and 342 mg Fe(NO 3 ) 3 ·9H 2 O, added to 150ml of GO aqueous solution, after stirring for 30min, dropwise added NaOH solution to adjust the pH of the mixture to 11;

[0038] 3. Add the above mixed solution to a hydrothermal kettle lined with polytetrafluoroethylene, and react at 180°C for 12h;

[0039] 4. The obtained precipitate was washed alternately with deionized water and absolute ethanol to pH=7, and the obtained RGO / CoFe 2 O 4 The precipitate was dispersed in 150ml of deionized water, according to the mass ratio of GO:AgNO 3 =1:1.26 Weigh 126mg AgNO 3 , added to the above mixture, stirred for 20min, according to the mass ratio of GO:NaBH 4 =1:5, weigh 500mg NaBH 4 Dissolved in 20ml of water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com