Permeable reactive barrier device for underground water treatment

A technology of infiltration reaction wall and groundwater, which is applied in the treatment of polluted groundwater/leachate, biological water/sewage treatment, water/sludge/sewage treatment, etc. To deal with problems such as large amount of sewage, to achieve the effect of low cost, good removal effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

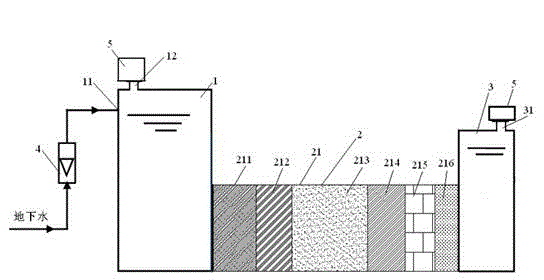

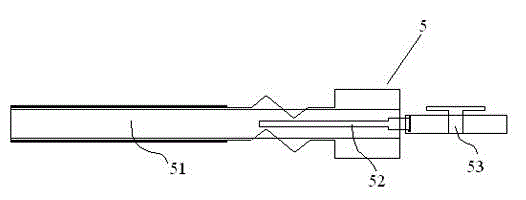

[0028] see figure 1 , the permeable reaction wall device for groundwater treatment according to the present invention comprises: a water inlet tank 1, a permeable reaction tank 2 and a water outlet tank 3 arranged in sequence along the groundwater flow direction, and the water inlet tank 1, the permeable reaction tank 2 and the water outlet tank 3 are provided with a mesh grid; the water inlet tank 1 is provided with a water inlet 11 on the other side wall of the permeable reaction tank 2, and a sampling port 12 is provided on the top; a reaction medium is provided in the permeable reaction tank 2 layer 21, the reaction medium layer 21 includes a first limestone layer 211, a first activated carbon layer 212, an iron filings layer 213, a porous ceramic filter plate 214 covered with a nano-ceramic filter membrane, and a second activated carbon layer that are sequentially stacked along the groundwater flow direction. layer 215, the second limestone layer 216; the top of the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com